Automatic Cashew Nut Premade Pouch Packing Machine | Horizontal Pouch Packing Machine

Model: LDSP-210A

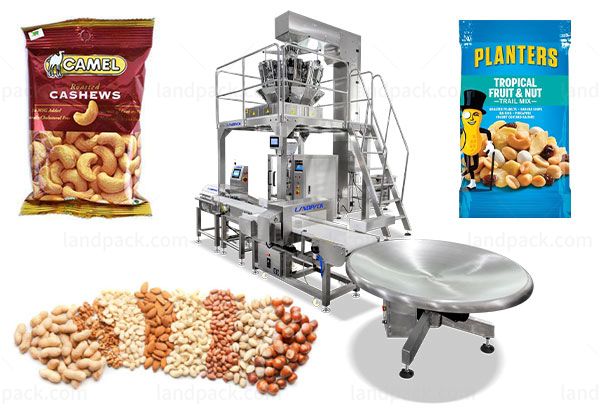

This automatic pouch packing machine is fast, clean, and efficient, easily handling various granular products.

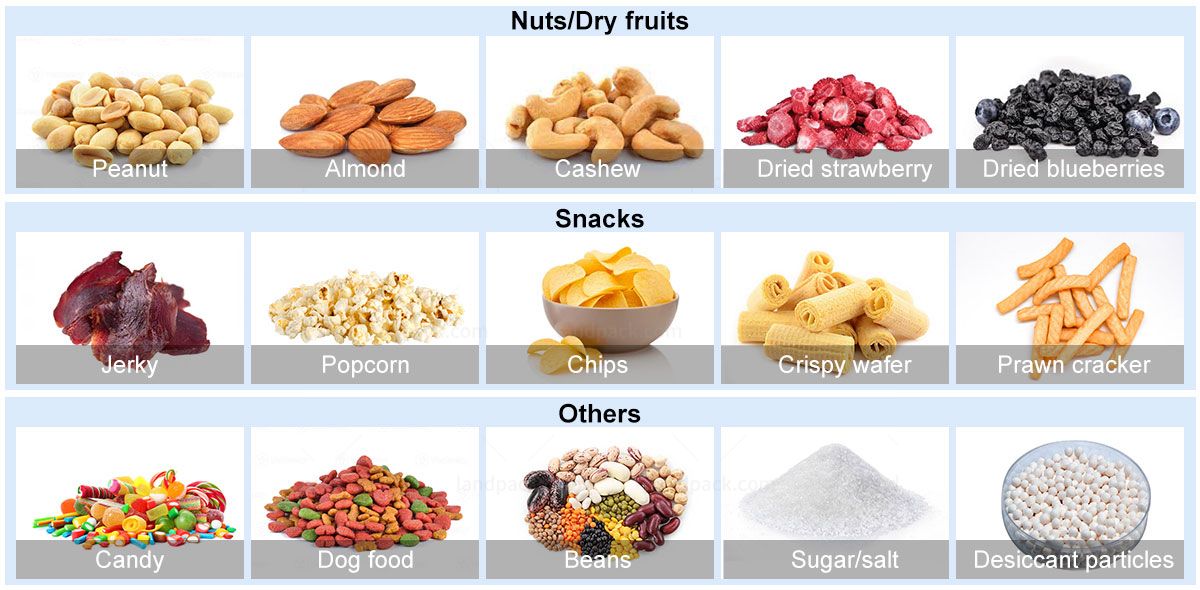

Application:

Using the Landpack horizontal pouch packaging machine, you can quickly and accurately fill packages of nuts and snacks. Our filling equipment is adaptable for packaging a variety of nuts and snacks, such as cashew, coffee beans, pet food, jerky, pretzel pieces, cheese balls, popcorn, sunflower seeds, puffed snacks, pistachios, almonds, raisins, and more.

What is a horizontal pouch packaging machine?

A horizontal premade pouch packing machine is a highly efficient, fully automatic packaging device. It is primarily used to automatically handle tasks such as picking up and opening premade pouches, filling them with materials, sealing, and discharging the finished product. Its core feature is the horizontal pouch handling method, which makes it suitable for various material forms (such as granules, powders, liquids, and solids) and different pouch specifications. It is widely used in industries like food, medicine, daily chemicals, and chemical products.

Application:

Food Industry

Solids: Nuts, candies, potato chips, coffee beans, pet food, etc.

Powders/Liquids: Flour, milk powder, seasonings, fruit juice, tomato sauce, hot pot base (requires a customized filling system).

Pharmaceutical Industry

For the precise and measured packaging of tablets, capsules, and granular medicines.

Daily Chemicals and Cosmetics Industry

For powder or paste products like laundry detergent, shampoo, facial masks, and foundation.

Industrial and Agricultural Sectors

For packaging seeds, fertilizers, feed, and chemical raw materials (such as granular pesticides).

Package Type:

Stand-up Pouch: Features a sturdy bottom gusset that allows it to stand upright on shelves, making it ideal for display and widely used for packaging nuts, coffee, and snacks.

M-shape Pouch: Designed to expand and hold larger volumes while maintaining a compact and stable structure, optimizing space efficiency.

Flat Pouch: A simple and cost-effective packaging solution, often used for single-serve or small-portion products like spices or snacks.

Zipper Pouch: Equipped with a resealable zipper closure to preserve freshness and ensure convenience, making it suitable for dried fruits, seeds, or pet food.

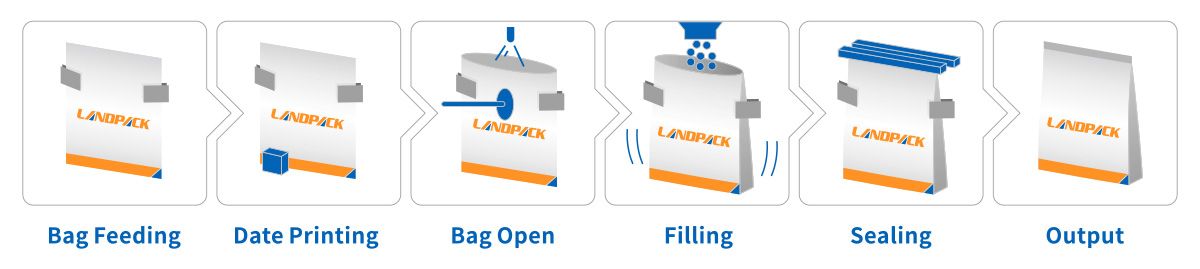

workflow:

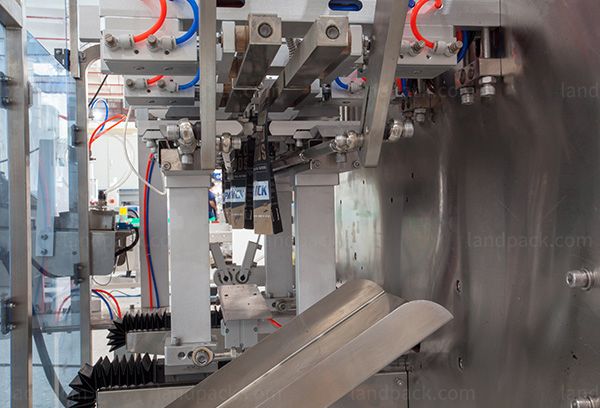

Giving Bag--Pre-made pouches or bags are loaded in bulk into the main bag magazine. This magazine is designed to move vertically. It lowers to facilitate easy loading of new bags. Once raised, a mechanical arm equipped with two vacuum suction cups picks up the top bag and transfers it to a mechanical gripper stationed on the rotary indexing table.

Date Printing--To meet production traceability and labeling requirements, a coding and marking printer, is integrated to print variable data like production dates, expiry dates, and batch numbers directly onto the packaging bag.

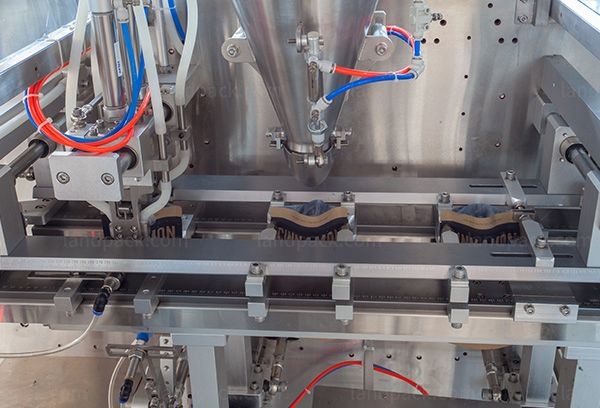

Opening Bag--At this station, suction cups grip and open the mouth of the packaging bag. Simultaneously, an air nozzle from above jets air to inflate and separate the bag's bottom gusset. A bag support plate is then inserted into the opened bag mouth to maintain its shape. A detection system (e.g., sensors or vision systems) verifies two critical conditions: firstly, the presence of a bag, and secondly, whether the bag mouth has been successfully opened. If either check fails (no bag or failed opening), the system signals the subsequent stations to skip operations like filling for this cycle.

Filling & Consolidate--Depending on the physical characteristics of the product being packaged (e.g., granules, powders, liquids, solids), an appropriate automated feeding system is configured. This could include auger fillers for powders, vibratory feeders for granules, pump systems for liquids, or volumetric cup fillers. This station handles the precise (metering) and delivery of the product into the awaiting opened bag.

Buffering (or Other)

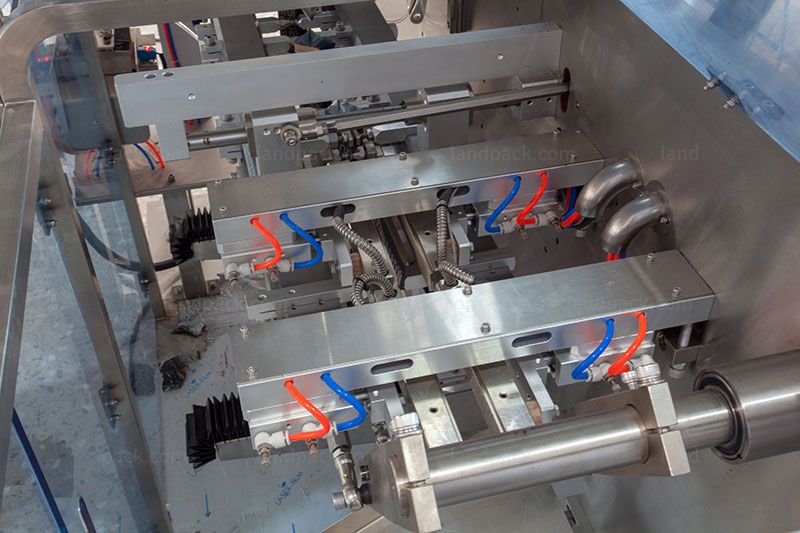

Heat Sealing 1--The mouth of the filled packaging bag is sealed using a pair of heated sealing bars (hot bar sealing or impulse sealing are common methods). The pattern impressed by the seal bars can often be customized (e.g., straight line, grid pattern, or other designs) based on sealing strength requirements and aesthetic preferences.

Heat Sealing 2--Immediately following the heat application, a pair of cold press bars or a cooling station engages the freshly made seal. This critical step rapidly cools and sets the molten plastic, solidifying the seal. It enhances seal strength, improves integrity, prevents seal wrinkling or distortion due to residual heat, and ensures a flat, aesthetically pleasing finish.

| Type | LDSP-160 | LDSP-210 | LDSP-260 |

| Bag Type | Stand-up Pouch, M-shape Pouch, Flat Pouch, Zipper Pouch, etc. | ||

| Bag Size | 110-230mm*80-160mm(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min | 20-50bags/min | 20-50bags/min |

| Machine weight | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of the product | ||

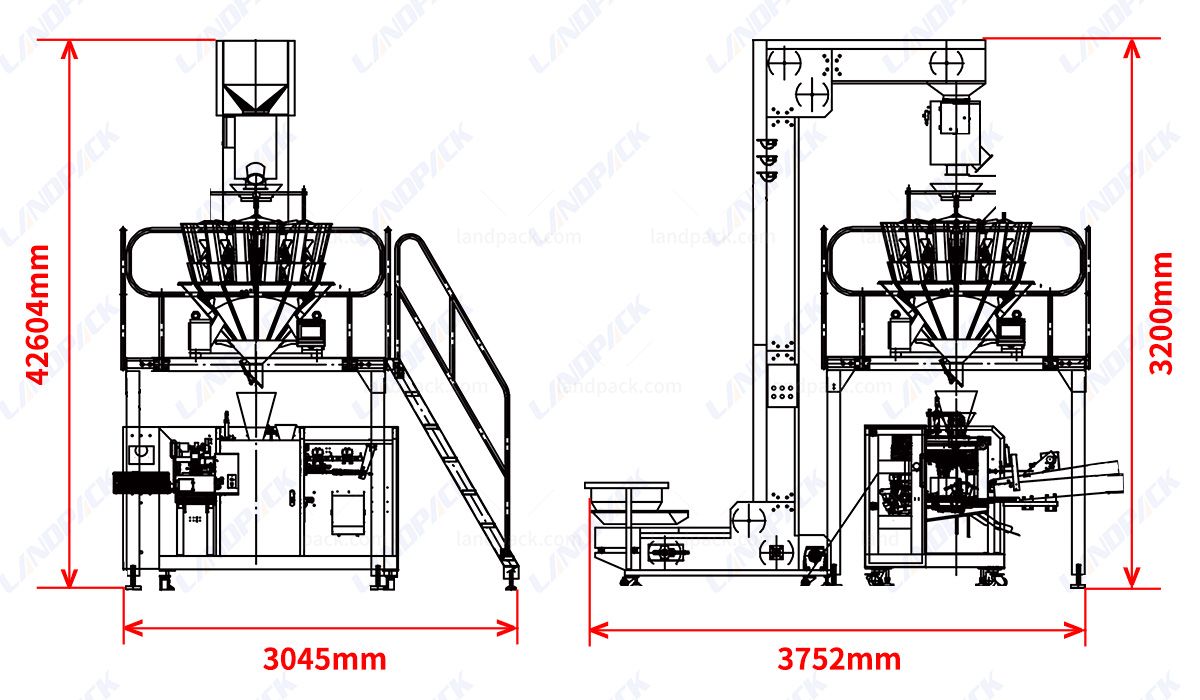

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) |

| Collocation | Screw metering, screw elevator | ||

Machine Key Components:

This doypack pouch packing machine is designed with a clear and practical structure. Each part plays an important role in ensuring smooth, efficient, and hygienic packaging:

* Z Type Conveyor

* Falling Metal Detection

* Multi-Head Weigher

* Control Panel

* Bag Feeding Device

* Filling System

* Sealing System

* Finished Product Conveyor

Feature:

Automatic Material Conveying The conveyor smoothly delivers products to the metal detection unit, ensuring continuous and efficient feeding without manual handling. This design improves production efficiency and reduces labor costs. |  |

| High-Precision 14-Head Weigher Equipped with a 14-head electronic weigher, the system provides precise and rapid weighing, guaranteeing accurate portion control while maintaining high packing speed. Ideal for granular products of different sizes. |

Falling Metal Detection System Metal detection is performed before weighing. This ensures maximum product safety while avoiding unnecessary bag waste when metal contaminants are detected. |  |

| Two heat sealing processes The filled bag mouth is sealed using a pair of heated sealing strips. Immediately after the heat is applied, a pair of cold press strips or cooling stations act on the newly created seal. |

High-Speed Performance The machine achieves speeds of up to 50 bags per minute, ensuring fast and stable production output. Perfect for meeting the demands of large-scale packaging while maintaining consistent quality. |  |

Get Price & More Detail