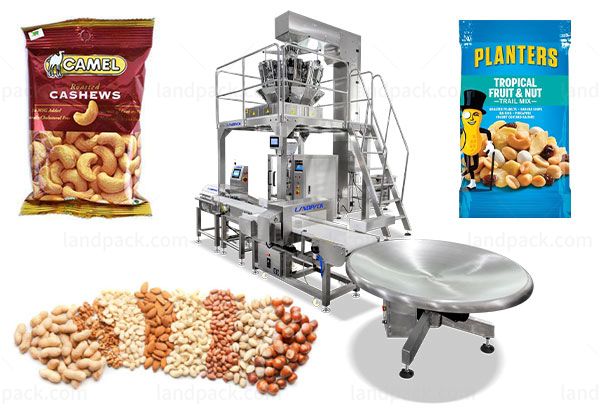

Nuts Packing Machine | Automatic Vertical Form Fill Seal Machine

Model: LD-380AS

The vertical packaging machine with a 2-head linear weigher is designed for compact, efficient weighing and packing of granular products.

Application:

This machine is suitable for packaging various nuts, beans, grains, seeds, snacks, and other free-flowing solids. It also supports non-food items such as hardware granules, small plastic parts, and pet treats.

Application:

This machine is suitable for packaging various nuts, beans, grains, seeds, snacks, and other free-flowing solids. It also supports non-food items such as hardware granules, small plastic parts, and pet treats.

Package Type:

This machine supports common pillow bags, gusseted bags, and flat pouches used for nuts, beans, grains, and small granular products. Optional tear notches, hanging holes, and printed film options allow flexible packaging styles for both food and non-food applications.

Suitable Products:

This vertical packing machine with a 2-head linear weigher is built for accurate, stable, and gentle handling of free-flowing granular products.

- Nuts & Seeds: almonds, cashews, peanuts, mixed nuts, sunflower seeds, pumpkin seeds

- Beans & Grains: red beans, soybeans, lentils, chickpeas, rice blends, small grains

- General Granular Products: pet treats, small hardware pieces, plastic pellets, dehydrated food bits

Process Workflow:

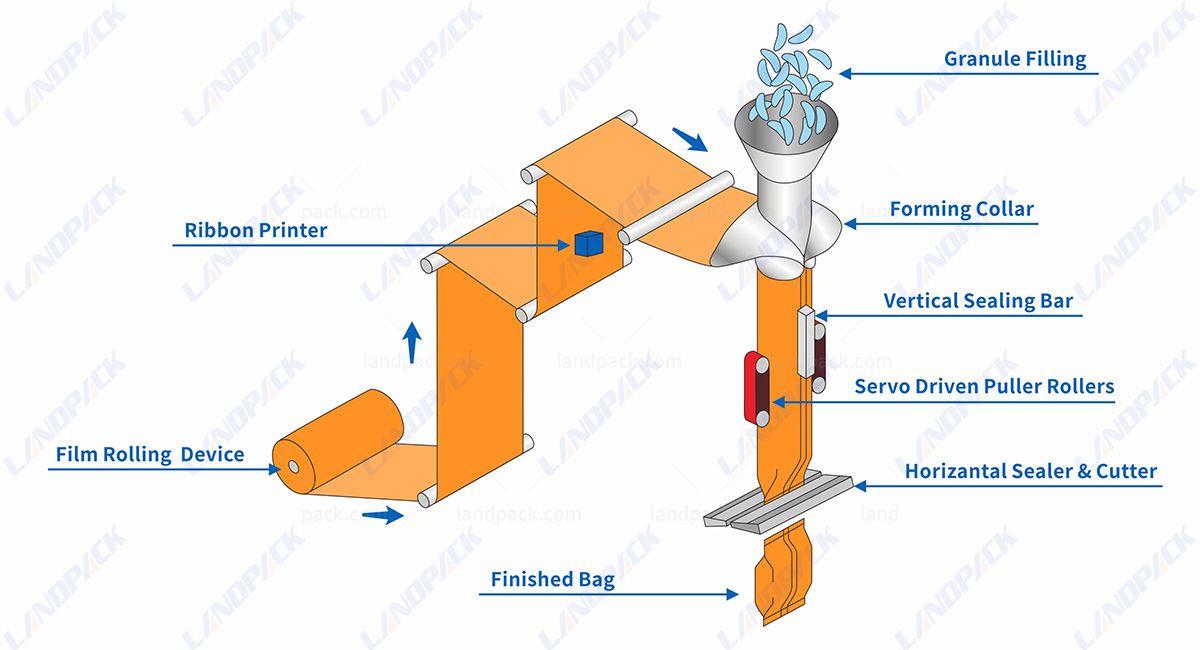

1. Product Feeding: Granular products such as nuts or beans are lifted or fed into the storage hopper.

2. Dual-Head Linear Weighing: Two independent weighing heads measure each portion accurately.

3. Film Unwinding & Bag Forming: The film roll is pulled downward and shaped into a pouch through the forming collar.

4. Vertical Sealing: The machine forms the back seal, securing the pouch structure and preparing it for the filling process.

5. Product Filling: Weighed products are released into the formed pouch.

6. Top Sealing & Cutting: The upper seal is applied, and each pouch is cut into individual bags.

7. Finished Bag Discharge: Completed pouches exit onto the conveyor.

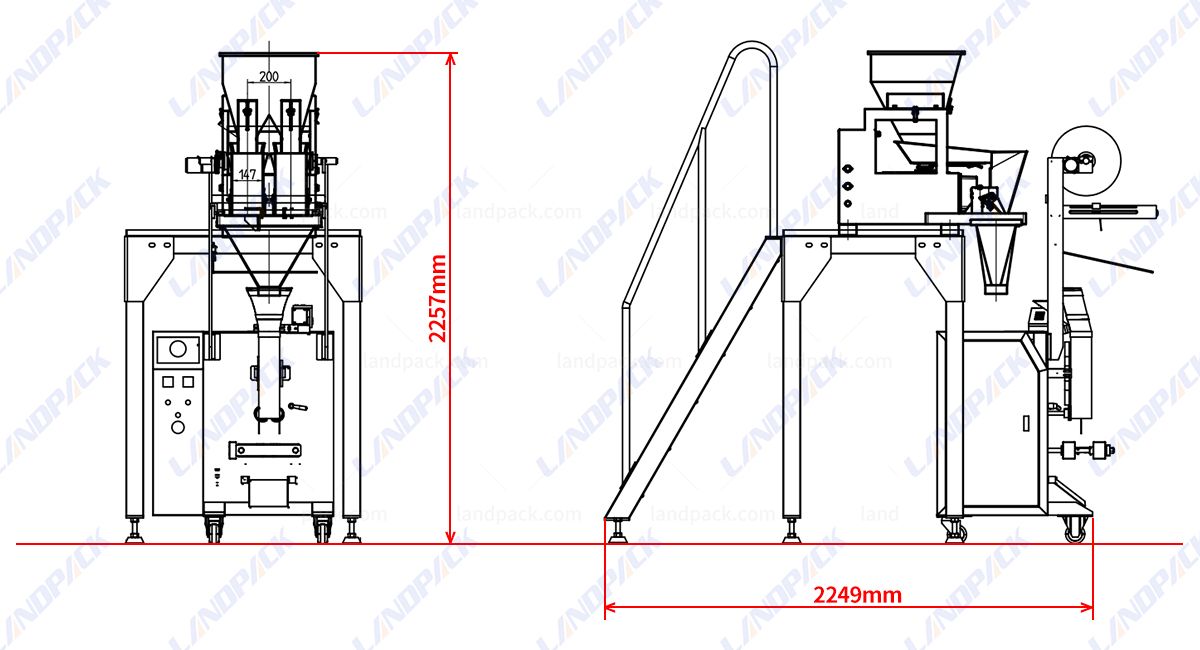

| Model | LD-320 | LD-380 |

| Film width | 120-320mm | 180-380mm |

| Bag length | 50-200mm | 60-280mm |

| Bag width | 50-150mm | 60-180mm |

| Diameter of film roll | Max.300mm | Max.320mm |

| Packing speed | 35-70bag/min | |

| Measuring range | 50-500ml | 50-750ml |

| Film thickness | 0.04-0.07mm | |

| Power | 220V 50/60Hz 2.2KW | 220V 50/60Hz 2.5KW |

| Machine size(L*W*H) | 970*680*1950mm | 1100*800*2150mm |

| Machine weight | About 300kg | About 450kg |

Machine Key Components:

1. Storage Tank

2. Film Rolling Device

3. 2 Heads Linear Weigher

4. Film Rolling Device

5. Touch Screen

6. Form Structure

7. Sealing Structure

Feature:

High-Accuracy Dual Linear Weighing System It is equipped with a two-head linear weigher, designed specifically for light and fragile products such as popcorn, which ensures a steady dosing, a minimal amount of giveaway and a gentle handling that prevents crushing. |  |

| Optimized for Fragile Snack Products The entire filling process is designed using gentle angles and a controlled height to minimize impact and protect chip, snacks, and other fine granules. |

Stable Film Transport & Smooth Bag Forming The film pulling system driven by a servo assures accurate alignment and smooth motion of the film making pouches that are consistently formed with neat edges and a uniform appearance. |  |

| Simple Operation using PLC and Touchscreen The intuitive interface lets you quickly make adjustment of parameters as well as recipe storage and monitoring in real-time. |

Efficient Heat-Sealing Structure High-quality sealing jaws offer secure, airtight seals when operating at high speeds. |  |

| Modular Design for Easy Cleaning & Maintenance Disassembly of hoppers without tools and contact components ensures quick cleaning between different flavors (butter cheese, caramel, and butter). |

Get Price & More Detail