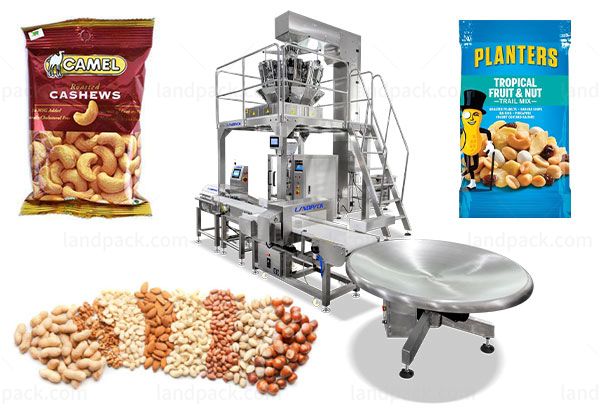

Automatic Mixed Nuts Snack Mini Doypack Packing Machine With Measure & Mixture

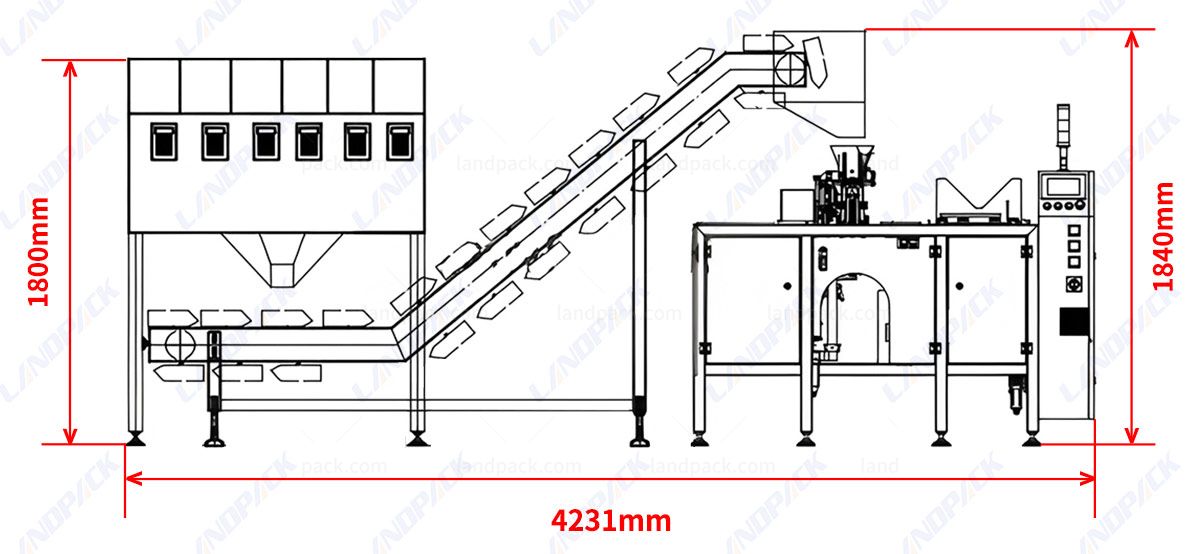

Model: LG1-300B

Automatic mini stand-up pouch packaging machine for mixed nut snacks. Features precise metering, mixing, filling, and sealing. Ideal for packaging mixed nuts, trail mixes, dried fruits, and snack blends in stand-up pouches.

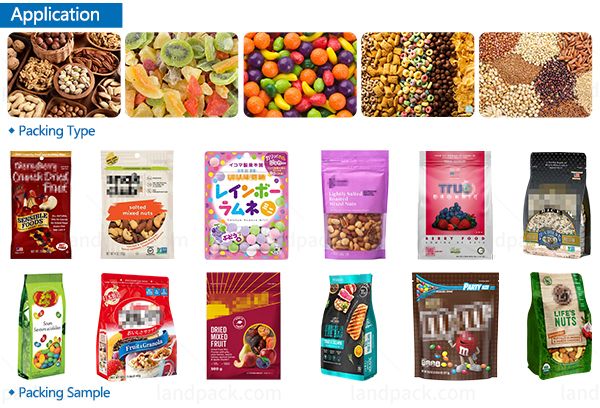

Application:

Ideal for mixed nuts, trail mixes, seeds, grains, beans, sugar, salt, puffed snacks, oatmeal, candies, and small pet food.

What is a Mini Doypack Packing Machine With Measure & Mixture?

Compact automatic pouch packaging machine designed for mixed granules. Integrates weighing, mixing, filling, and sealing functions to ensure accuracy, freshness, and premium presentation.

Package Type:

This machine is compatible with various premade pouch styles, offering flexibility for different product needs. Suitable bag types include stand-up pouches (doypacks), flat pouches, zipper resealable bags, gusseted bags, and M-shaped bottom bags.

Suitable Products:

1. Nuts, Dried Fruits, and Trail Mixes:

almonds, cashews, walnuts, cranberries, apricots, mangoes, cranberries, apricots,

2. Confectionery, Snacks, and Bakery Goods:

candies, gummies, jelly beans, crackers, popcorn, and extruded snacks, cookies and biscuits

3. Grains, Cereals, and Health Foods:

breakfast cereals and granola, rice and grains, beans and legumes

4. Pet Food and Non-Food Granular Products:

Pet Food, horticultural products, water softener salts, desiccant beads, screws, nuts, or bolts

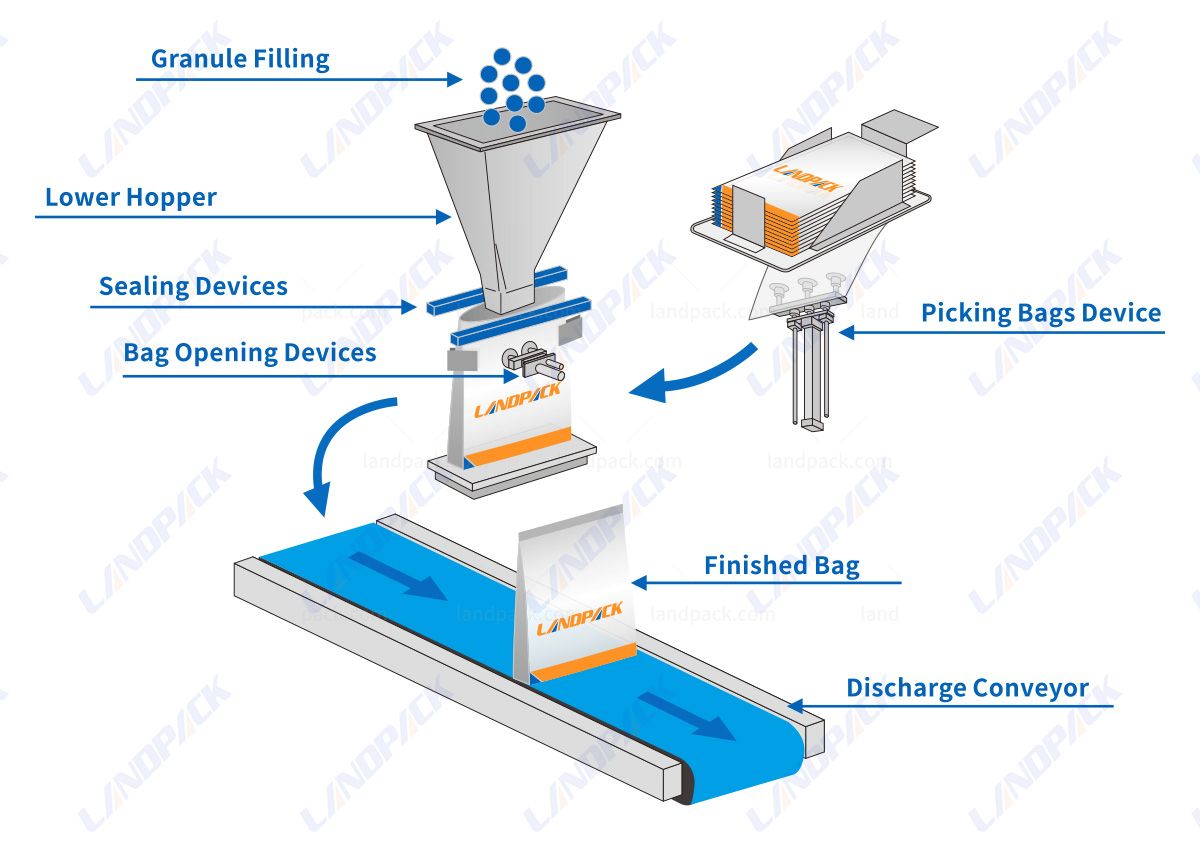

Process Workflow:

Measure & Mix: Different granular ingredients, such as nuts or seeds, are accurately weighed and evenly mixed.

Chain Conveyor Filler: The blended materials are smoothly transported by the chain conveyor to the filling station.

Bag Storage: Premade pouches are neatly stacked and stored in the bag magazine.

Bag Feeding: The system automatically picks and positions each pouch for filling.

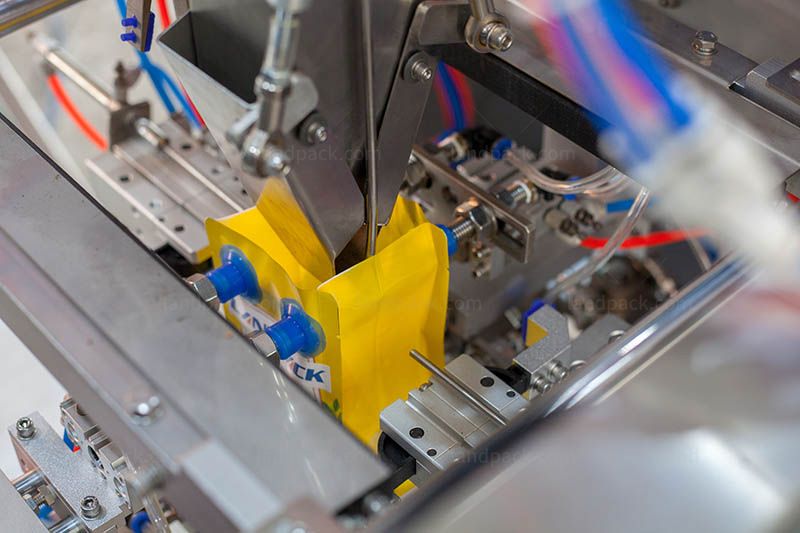

Bag Opening: The vacuum suction device opens the bag mouth precisely.

Filling & Nitrogen Injection: Granular materials are dispensed into the opened pouch, while nitrogen is injected simultaneously to maintain product freshness and extend shelf life.

Sealing: The filled pouch is securely heat-sealed under controlled temperature and pressure.

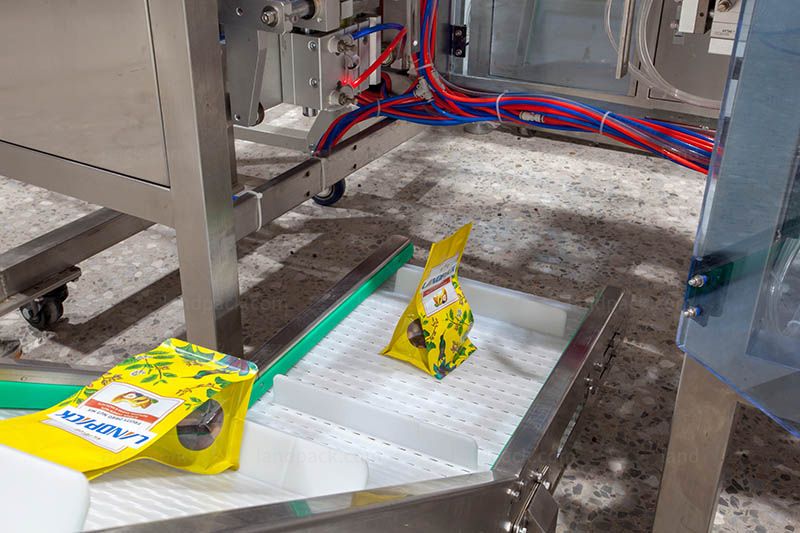

Output: Finally, the sealed pouches are conveyed to the output belt for easy collection.

| Model | LDB-300 | LDB-430 | LDB-600 |

| Bag Material | Multilayer Composite Premade Bag (e.g.: PET/PE) | ||

| Bag Type | 3 Side Seal Bag, Stand-up Bag, M Shape Pouch | ||

| Upgradable Bag Type | Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device) | ||

| Size Range | 80mm≤W≤300mm, 100mm≤L≤300mm | 80mm≤W≤300mm, 100mm≤L≤430mm | 250mm≤W≤500mm, 380mm≤L≤600mm |

| Speed | 0-15bags/min | 0-10bags/min | |

| Sealing Type | Straight grain, the pitch is 1mm (Optional reticulate) | ||

| Sealing Width | 10mm (5-20mm can be customized) | ||

| Voltage | 220V, Single-phase, 50/60HZ, 1.2KW | ||

| Air Pressure | 0.65Mpa | ||

| Air Consumption | 0.3m³/min (Standard machine, no additional function) | ||

| Body Dimension | 1770*600*1230mm | 1677*1140*1450mm | |

| Machine Weight | 300 kg | 350 kg | 450 kg |

Machine Key Components:

1. 6 Heads Linear Weigher

2. Chain Conveyor Filler

3. Control Panel

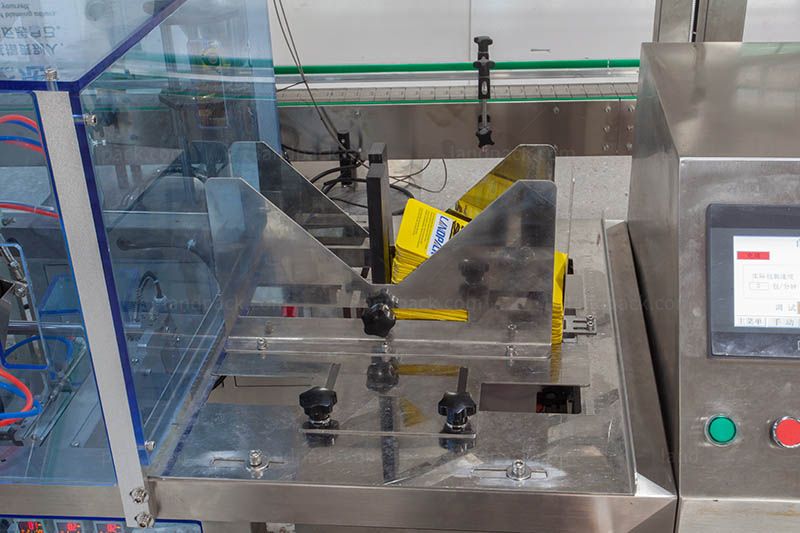

4. Bag Feeding Device

5. Mini Doypack Machine

6. Electrical Box

7. Finished Product Conveyor

6 Heads Linear Weigher Ensures accurate and consistent weighing of multiple granular ingredients. Each head operates independently for high-speed, precise dosing. |  |

| Chain Conveyor Filler Transports materials steadily to the filling station. Its smooth chain design minimizes spillage and ensures even product feeding during the packaging process. |

Bag Feeding Device Automatically picks up and positions premade pouches for filling. Ensures stable pouch opening, accurate placement, and reliable operation to enhance packaging efficiency. |  |

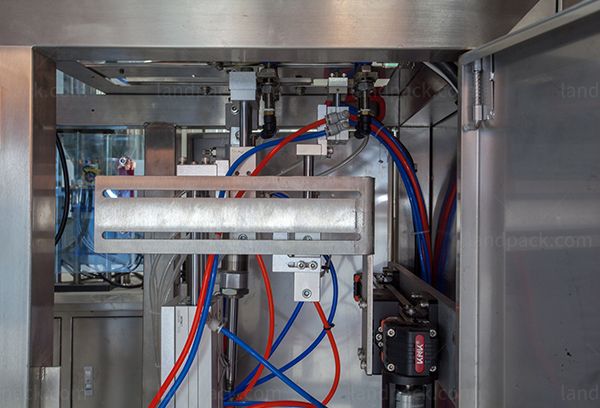

| Bag Opening Device Uses vacuum suction and mechanical arms to automatically open each premade pouch with precision. Ensures smooth entry for product filling and minimizes air leakage or misalignment during packaging. |

Heat Sealing Device Applies stable temperature and pressure to create strong, airtight seals. |  |

| Finished Product Conveyor Transports sealed pouches smoothly to the collection area. Supports continuous production flow and allows easy connection to downstream packaging or inspection systems. |

Get Price & More Detail