Automatic Carton Case Packing System with Palletizer Machine For Pouch

Model: LD-ZHJ300

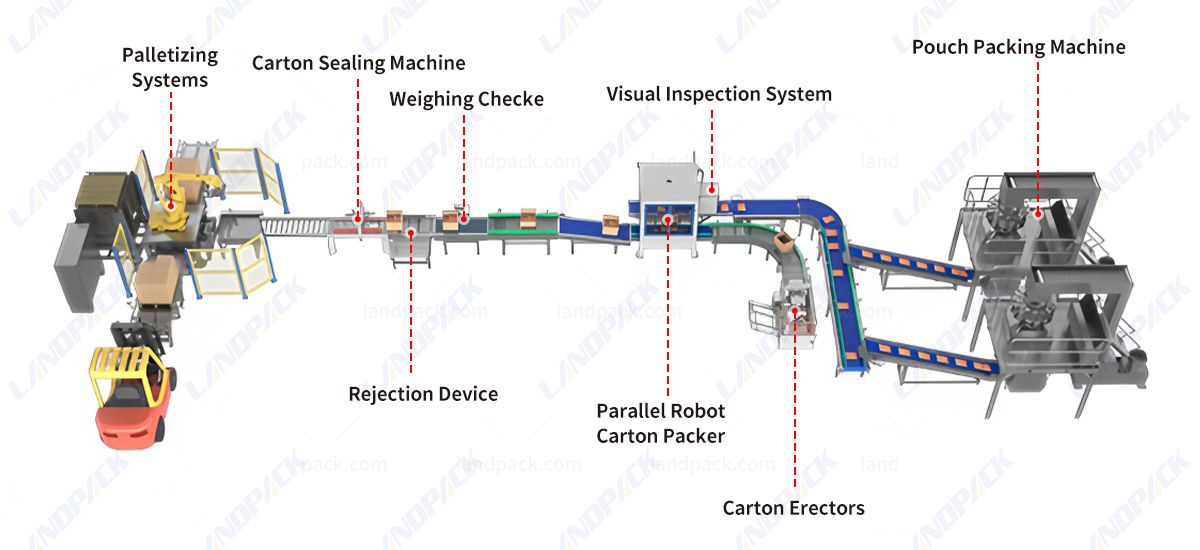

This automatic pouch packing system is a fully integrated end-of-line solution, combining vertical packaging machine, weighing detector, intelligent case packing robot, carton erectors, and palletizer machine.

Designed for continuous high-efficiency production, the professional packaging system ensures accurate bag counting, stable case packing, and neat pallet output.

Application:

Suitable for manufacturers seeking a packing solution for granular products in pouch, this packing system handles the entire process from primary bag packaging to secondary cartoning and final palletizing.

Designed for stable handling of pillow bags, premade pouch, and gusseted pouches, Widely used for food grains, seeds, pet food, chemical granules.

Application:

Suitable for manufacturers seeking a packing solution for granular products in pouch, this packing system handles the entire process from primary bag packaging to secondary cartoning and final palletizing.

Designed for stable handling of pillow bags, premade pouch, and gusseted pouches, Widely used for food grains, seeds, pet food, chemical granules.

Package Type:

This smart packaging system supports pillow pouches, back-sealing bags, gusseted bags, and sachets that have been pre-packed by the vertical packaging machine. Finished bags are automatically counted, arranged, packed into corrugated cartons, sealed, and palletized.

Suitable Products:

This packing system is especially suitable for products requiring high-speed end-of-line packing:

1. Granular Products: Rice, beans, lentils, corn kernels, seeds, coffee beans, nuts, pet food kibbles, plastic pellets, chemical granules, fertilizer particles.

2. Food & Agricultural Products: Sugar, salt, frozen vegetables, dried fruits, grains, cereal mixes, animal feed pellets.

3. Chemical & Industrial Granules: Detergent granules, resin pellets, plastic masterbatch, desiccant beads, mineral particles.

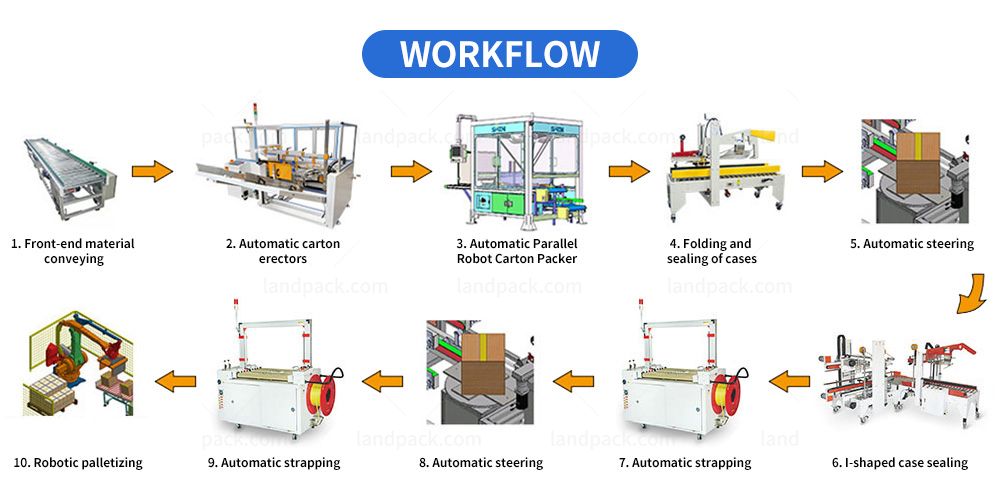

Workflow:

1. Front-end Material Conveying: Convey finished bags from the packaging line to the cartoning system.

2. Automatic Carton Erectors: Automatically form and open cartons from flat blanks.

3. Automatic Parallel Robot Carton Packer: Pick and place bagged products into cartons according to set patterns.

4. Folding and Sealing of Cases: Fold carton flaps and seal cartons automatically.

5. Automatic Steering: Adjust carton orientation for the next process.

6. I-shaped Case Sealing: Apply I-shaped tape sealing to cartons.

7. Automatic Strapping: Strap cartons for transport stability.

8. Automatic Steering: Redirect cartons to the next station.

9. Automatic Strapping: Perform secondary strapping if required.

10. Robotic Palletizing: Stack cartons onto pallets automatically.

| Box Case Sealer Sealing Machine | |||||

| Model | LD-ZHJ300 | ||||

| Power supply | 220V, 50Hz, 0.75kW | ||||

| Air pressure requirement | 0.5-0.8MPa | ||||

| Machine material | Aluminum + stainless steel | ||||

| Applicable | L: 120-300mm, W: 30-150mm, H: 20-60mm | ||||

| Size of carton | Customizable | ||||

| Box material | 300-450g cardboard paper, corrugated paper | ||||

| Working speed | 30-50 cartons/min | ||||

| Machine size | 4008*1354*1633 mm | ||||

| Weight | About 1500kg | ||||

| Carton erecting machine | |||||

| Carton opening speed | 10-12 cartons/min | ||||

| Carton size range | L: 270-450*W: 150-400*H: 100-400mm (Min and max cannot exist at the same time) | ||||

| Power supply | 220V, 50/60Hz, 1 Phase | ||||

| Power | 2400W | ||||

| Adhesive tape width | 48/60/75mm | ||||

| Carton storage quantity | 80-100pcs(800-1000mm) | ||||

| Air consumption | 450NL/min | ||||

| Air compressing | 6kg/cm³ | ||||

| Discharge table height | 600+30 mm | ||||

| Machine size | L2100*W2100*H1450mm | ||||

| Machine weight | 450Kg | ||||

| Automatic Carton Packing Machine | |||||

| Model | LD-B8 | LD-B18 | LD-B30 | LD-B42 | LD-B48 |

| Capacity | 480case/h | 1100case/h | 1800case/h | 2500case/h | 2800case/h |

| Air consumption | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ |

| Power | 3.7KW | 3.7KW | 4.5KW | 4.5KW | 5.2KW |

| Suitable products | Glass bottles, pet bottles, tin cans, bags, small boxes, and so on(customized) | ||||

| Packing way | Paper carton packer, plastic boxes(customized) | ||||

| Packing method | Side push, drop, servo, sprocket, robot, spider hand(customized) | ||||

| Carton Box Case Sealer | |||||

| Voltage | 220V, 60HZ | ||||

| Table height | 620-900mm | ||||

| Tape | W: 48-79mm | ||||

| Carton size | L: 200-600*W: 150-500*H: 150-500mm | ||||

| Machine weight | 165KG | ||||

Machine Key Components:

1. Palletizing Systems

2. Carton Sealing Machine

3. Weighing Checker

4. Rejection Device

5. Visual Inspection System

6. Parallel Robot Carton Packer

7. Pouch Packing Machine

8. Carton Erectors

Feature:

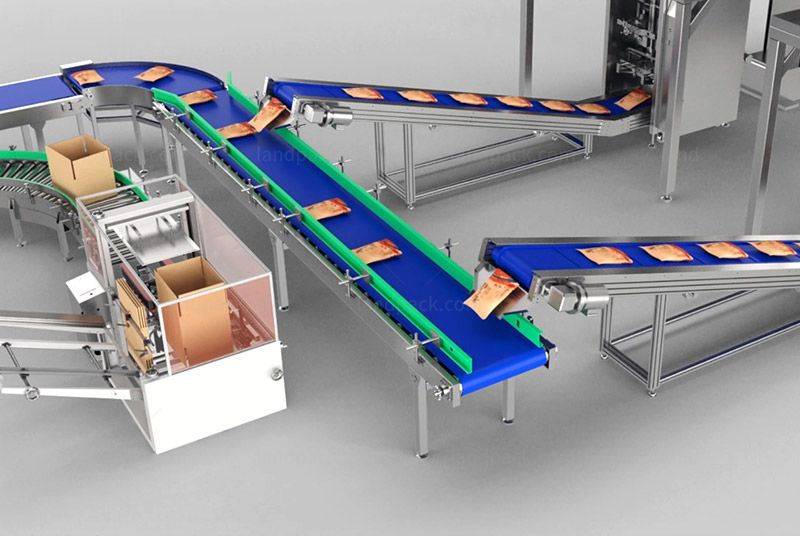

The finished bag output and Carton Erecting Automatically transfers bags that are finished from the packaging line, while simultaneously building cartons, which ensures smooth and steady product flow as well as steady carton formation for continuous, high-speed operation. |  |

| Automated Case Packing The intelligent case packing robot for packing cases accurately chooses and packs bagged goods into boxes, ensuring flexibility for various bag sizes and packing patterns. |

Case Sealing The automatic cartons sealer ensures a secure and constant sealing using durable tape solutions, enhancing the quality of the carton as well as safety for transport. |  |

| Palletizing A palletizer machine is able to stack sealed cartons according to predefined patterns and produces tidy, sturdy pallets that are suitable for storage. |

Get Price & More Detail