Liquid Detergent Filling Machine | Packing System

Model: LD-ALF01

A liquid detergent filling machine integrating bottle conveying, large-capacity mixing, multi-head gear pump filling, capping, labeling, sleeve shrinking, and stretch wrapping.

The filling line is designed for viscous and foaming liquids, ensuring stable filling accuracy, clean operation, and efficient secondary packaging.

Application:

An automatic liquid filling line for 40 bottles/min.

Supports efficient handling of viscous detergents from mixing to secondary packaging, ideal for liquid manufacturers seeking consistent filling accuracy, reduced labor, and ready-to-ship packed bottles.

Application:

An automatic liquid filling line for 40 bottles/min.

Supports efficient handling of viscous detergents from mixing to secondary packaging, ideal for liquid manufacturers seeking consistent filling accuracy, reduced labor, and ready-to-ship packed bottles.

Package Type:

Designed for plastic bottles, glass jars, metal tins, and cans in different shapes.

Supports single packing, sleeve-wrapped multipacks, and pallet-level stretch film wrapping.

Suitable Products:

This automatic bottle filling machine is designed for stable handling of viscous and foaming liquids:

1. Household Cleaning Products: Dishwashing liquid, laundry detergent, fabric softener, floor cleaner, glass cleaner, toilet cleaner, kitchen degreaser.

2. Personal Care & Hygiene Products: Liquid hand soap, hand wash, body wash, shampoo, disinfectant liquid, antiseptic solutions.

3. Industrial & Institutional Liquids: Industrial detergents, surface cleaners, sanitizing solutions, commercial-use cleaning chemicals, bulk liquid cleaners.

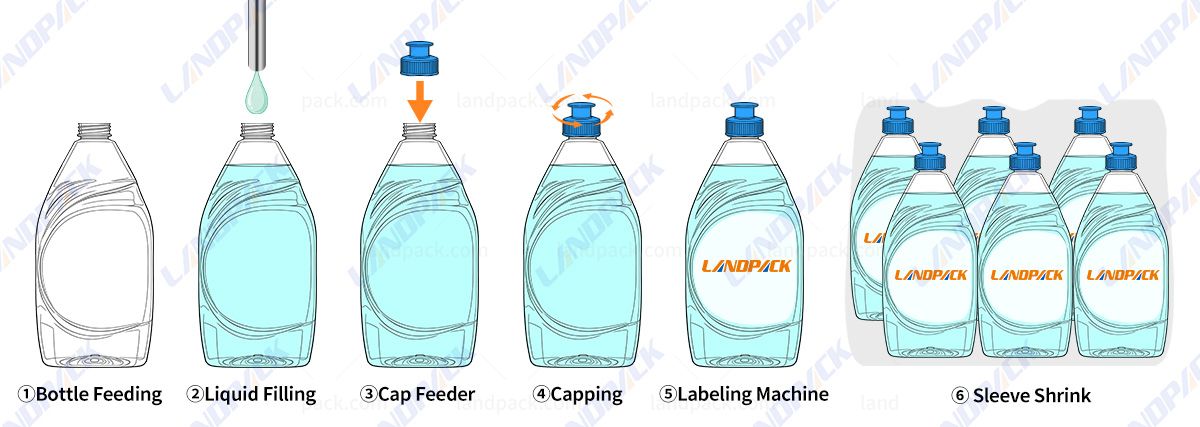

Workflow:

1. Bottle Unscrambling & Conveying: Empty bottles are automatically oriented and conveyed smoothly into the filling line.

2. Liquid Mixing & Storage: Detergent is fully mixed in the stirring tank to ensure uniform consistency before filling.

3. Gear Pump Filling: Six gear pumps perform precise, splash-free filling for viscous liquid products.

4. Automatic Capping: Caps are applied and tightened with stable torque to ensure leak-free sealing.

5. Labeling: Front and back labels are applied accurately to different bottle shapes.

6. Shrink Wrapping & Output: Finished bottles are shrink-wrapped and collected for storage or shipment.

Product Name | Automatic Liquid Filling Production Line |

Model | LD-ALF01 |

Filling Range | 50-1000ml(Customizable) |

Filling Speed | 15-50 bottle/min |

Measurement accuracy | ±1% |

Power | 2 KW |

Working power supply | 220V、50Hz |

Working pressure | 0.6-0.8MPa |

Weight | 400kg |

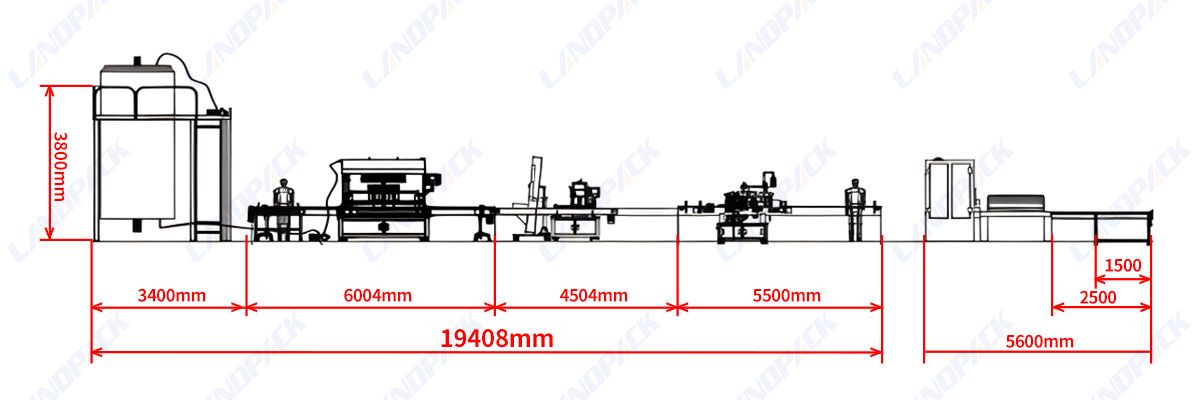

Size | L4000*W1320*H2090(mm) |

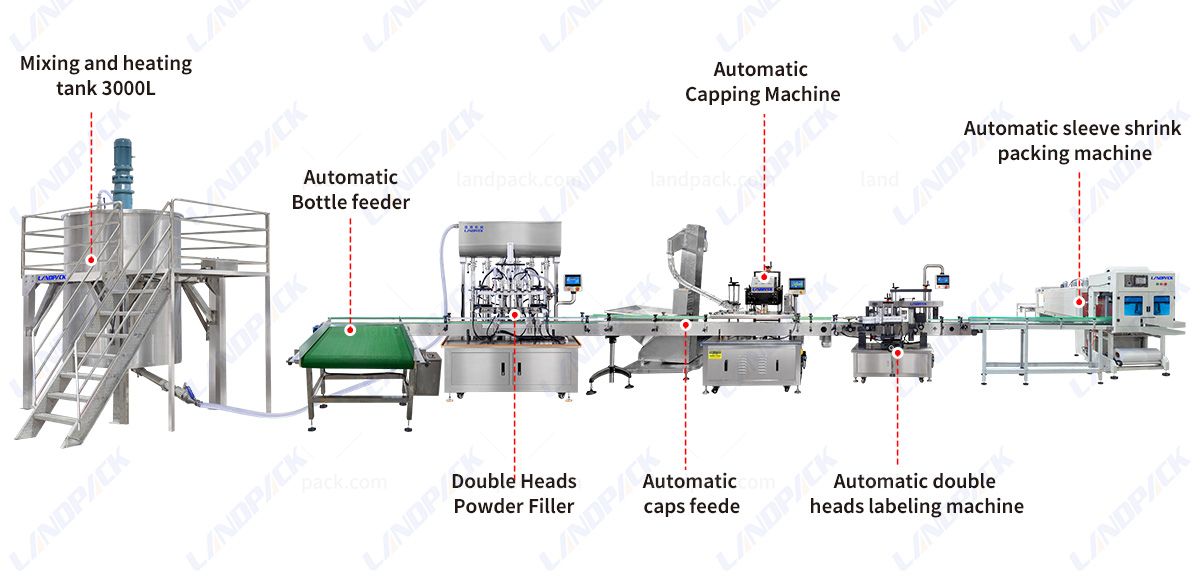

Machine Key Components:

1.Mixing and heating tank 3000L

2.Automatic bottle feeder

3.Automatic capping machine

4.Six heads liquid filler

5.Automatic caps feeder

6.Automatic sleeve shrink packing machine

7.Automatic double heads labeling machine

Feature:

Large-Capacity Mixing System Equipped with a 4 ton mixing tank, it ensures consistency in formulation and constant material supply, decreasing batches and ensuring reliable production. |  |

| Multi-Head Gear Pump Filling The six-head gear pump filling machine offers precise and consistent dosing for foaming and viscous liquids, which reduces splashing, dripping and waste product. |

Stable Bottle Handling and Conveying Positioning and conveying of bottles is designed to facilitate smooth flow between capping, filling, and labeling stations, which reduces the likelihood of tipping bottles and causing line stoppages. |  |

| Reliable Capping and Labeling Automated capping and double-sided labeling assures secure closures and consistent label positioning appropriate for different bottles of different shapes and sizes. |

Integrated Sleeve Shrinking Packaging The sleeve wrapping system that is automated and heat shrinking system allows efficient single or bundle bottle packaging, enhancing the appearance of products and retail ready. |  |

| End-of-Line Stretch Wrapping This stretch wrap unit is used to secure packaged products for palletizing and ensuring stability during transport and storage. |

Get Price & More Detail