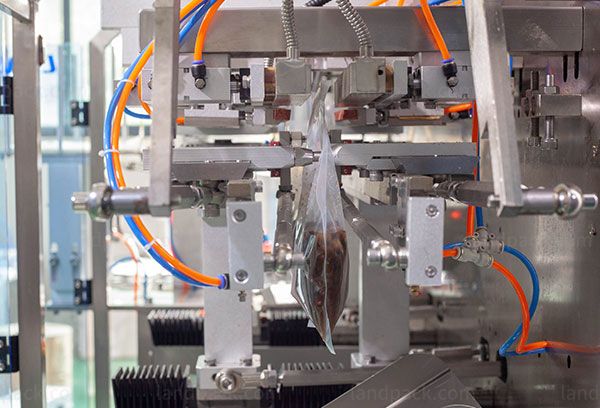

4 Linear Weigher Pickle Horizontal Premade Pouch Filling Sealing Machine

Model: LDSP-210X

Application:

Suitable for packing grains and particles into stand-up pouch doypack pouches premade pouches such as pickles, kimchi, pickled cucumber, kelp, peanuts, candy, beans, granular medicine, seed, etc.

Application:

4 linear weigher pickle horizontal premade pouch filling sealing machine, is also versatile, as it can handle a wide range of products, from food to non-food items.

Examples:

Pickles, kimchi, pickled cucumber, kelp, peanuts, candy, beans, granular medicine, seed, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristic.

Packaging Examples:

| Model | LDSP-210X |

| Packing material | 3-side, four edge-sealing bags, self-reliance bag, handbag, spout bag, zipper bag, compound bag, etc |

| Bag Size | W: 100-210 mm |

| Filling Range | 20-1000g |

| Packing Speed | 20-50 bags/min(speed is determined by the product filling quantity) |

| Average precision | ≤±1% |

| Total Power | 2.5KW |

| Weight | 900 KG |

| Main standard parts | 1. Code printer 2. PLC control system 3. Bag opening device 4. Vibration device 5. Cylinder 6. Electromagnetic valve 7. Temperaturecontroller 8. Vacuum pump 9. Inverter 10. Output system |

1.Versatile Bag Size Compatibility: Our flexible machine is designed to accommodate a wide range of bag sizes, making it suitable for packaging sauce, meat, and vegetables with vacuum sealing.

2.Precise Weight Control: With a weighing range of 200g to 1.5kg, our machine allows you to set the target weight easily on the touch screen, ensuring accurate and consistent packaging.

3.Customizable Packaging Solutions: Our machine offers the flexibility to adapt to different product types and sizes, providing tailored packaging solutions for your specific needs.

4.Efficient and Time-Saving: Automating the packaging process with our machine helps streamline operations, saving valuable time and increasing productivity.

5.High-Quality Vacuum Sealing: Our machine utilizes advanced vacuum sealing technology to ensure optimal freshness and extended shelf life for your sauce, meat, and vegetable products.

6.User-Friendly Interface: The touchscreen interface makes it easy to operate and adjust settings, allowing for seamless integration into your production line.

7.Reliable and Durable Construction: Built with high-quality materials and components, our machine is designed to withstand rigorous production environments, ensuring long-lasting performance.

8.Compliance with Food Safety Standards: Our machine adheres to strict food safety regulations, incorporating features that promote hygienic packaging practices and protect the integrity of your products.

9.Cost-Effective Solution: By optimizing packaging efficiency and reducing material waste, our machine helps lower overall packaging costs, contributing to improved profitability.

10.Enhanced Product Presentation: The precise weight control and customizable packaging options offered by our machine result in visually appealing and well-packaged products, enhancing their market appeal and customer satisfaction.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail