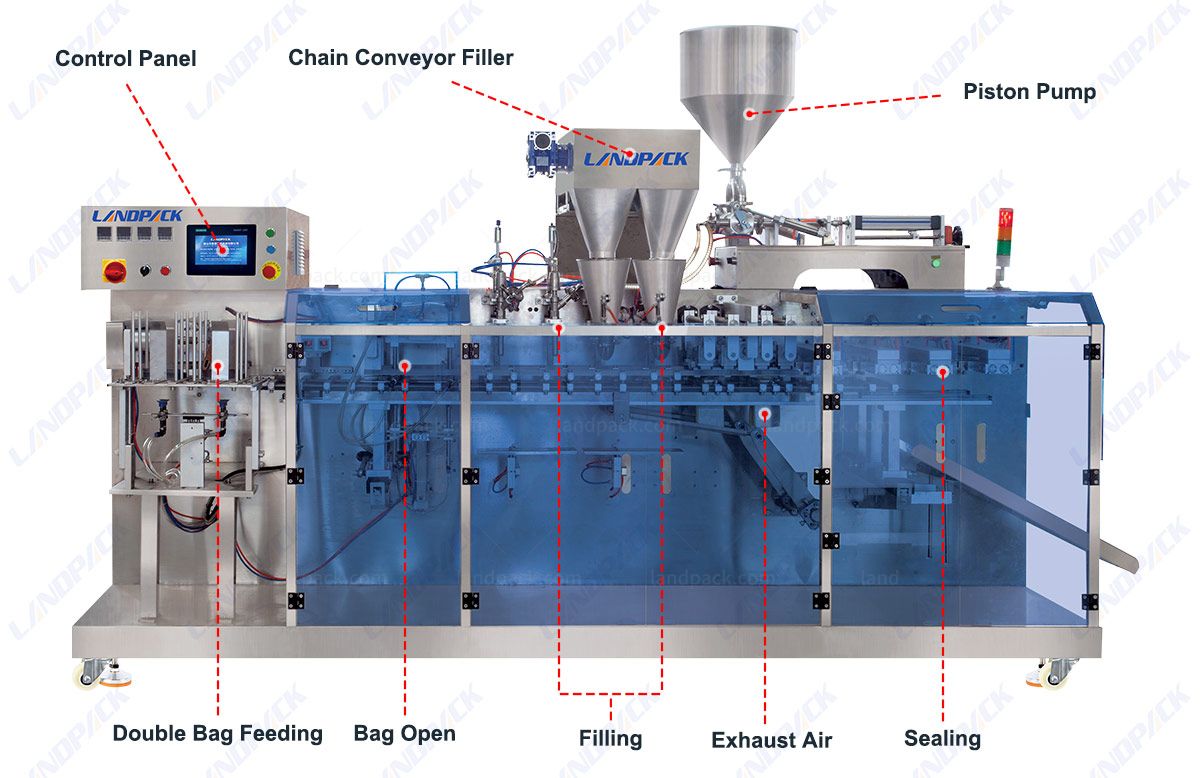

High Speed Duplex Horizontal Pouch Pickles Packing Machine

Model: LDSP-140L+B

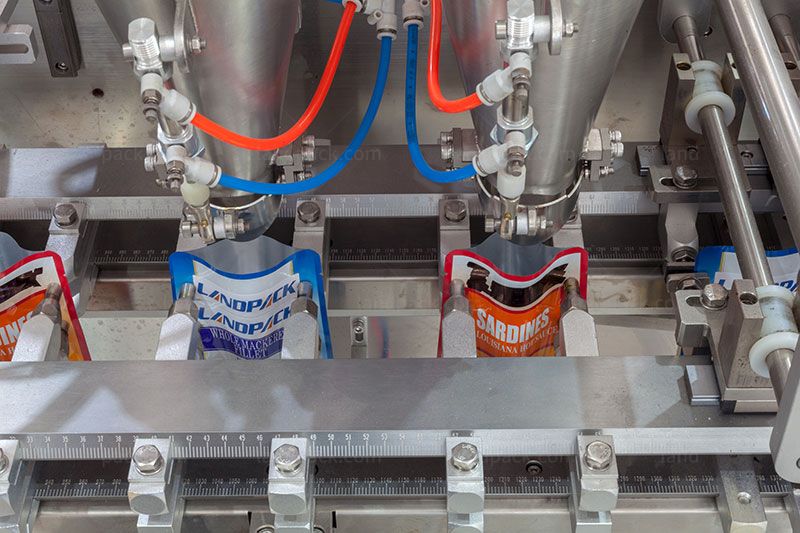

The filling system is optimized for messy, mixed products. It ensures an accurate amount of both the solid pieces and the liquid (like a sauce or brine) goes into every pouch, all while keeping the sealing area clean. This guarantees a strong, reliable seal and a professional look for your finished product.

Application:

This duplex horizontal pouch packing machine is specifically designed for products that contain both solids and liquids—like kimchi, pickled vegetables, saucy fish snacks, or other ready-to-eat meals.

What is a Duplex Horizontal Pouch Packing Machine?

It's key feature is the "duplex" system, which fills and seals two pouches at once. This effectively doubles your output compared to a standard machine, making it a great fit for high-volume production.

Application:

It offers wide adaptability across different industries, ensuring high precision and efficiency. Typical applications include:

- Snacks & Ready Meals

Pickled cucumber, fruit mix, soft-boiled eggs, Thai-style chicken feet, Ready-to-eat side dishes and small portioned meal packs

- Meat & Seafood Products

Fish meat with sauce, chicken cubes with gravy, cooked beans with sauce, rice with curry, and marinated seafood

- Dairy & Dessert Fillings

Yogurt flavored with jams made from fruit custard cream mix of chocolate sauce suking pudding, jelly, and mousse desserts

Package Type:

The double track horizontal pouch packing machine is compatible with a wide range of premade pouch types, including zip lock bags, stand-up pouches, M-shape gusset bags, and other customized pouch styles.

Workflow:

The Operational Sequence:

Dual Pouch Infeed - The process begins as the machine simultaneously grips and feeds two separate premade pouches into the conveyor system.

Pouch Preparation - Both pouches are securely opened and held in position, preparing them for the two-stage filling process.

Liquid Dosing - A precise, pre-measured volume of the liquid component (such as a sauce, oil, or brine) is dispensed into each open pouch.

Solid Ingredient Filling - Immediately following the liquid, the solid or granular items (like vegetables, meat chunks, or snack pieces) are accurately deposited into the pouches.

Air Evacuation - To preserve freshness and create a compact package, excess air is vacuumed from inside each pouch before sealing.

Hermetic Sealing - A high-integrity heat seal is applied to the top of both pouches, creating a secure and leak-proof closure.

Final Discharge - The completed, sealed pouches are then released from the machine onto an output conveyor, ready for final cartoning and distribution.

| Type | LDSP-160 | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, doypack, box pouch, zipper pouch, stand up pouch, stand up pouch with hole, kraft paper bag, side gusset bag, etc. | ||

| Bag Size | 110-230mm*80-160mm(L*W) | 100-210mm/110-320mm(L*W) | 140-260mm/160-380mm(L*W) |

| Filling Range | 20g-500g | 20g-1kg | 20g-1kg |

| Packing Speed | 20-45 bags/min | 20-50 bags/min | 20-40 bags/min |

| Machine weight | 800KG | 900KG | 900KG |

| Total Power | 2.5KW | 2.5KW | 2.5KW |

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | ||

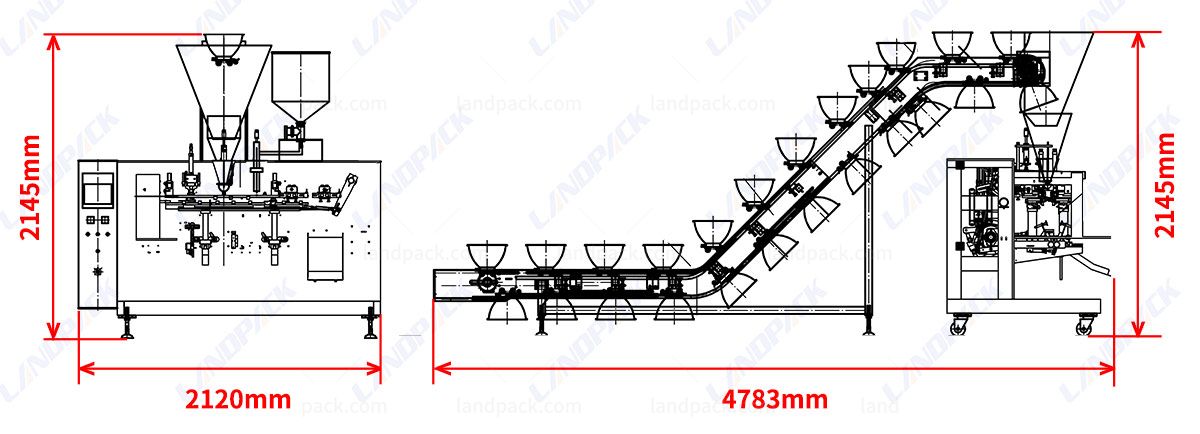

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) |

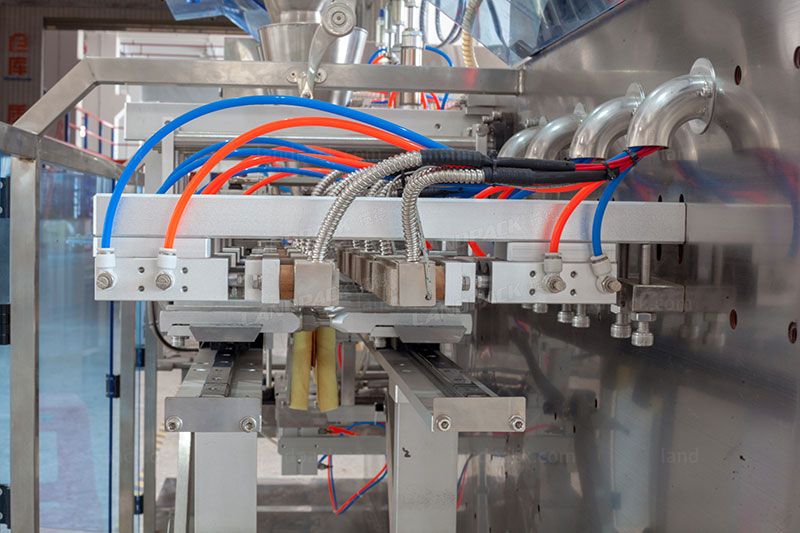

Machine Key Components:

* Control Panel

* Double Bag Feeding

* Double Bag Open

* Chain Conveyor Filler

* Double Bag Filling

* Piston Pump

* Exhaust Air

* Double Bag Sealing

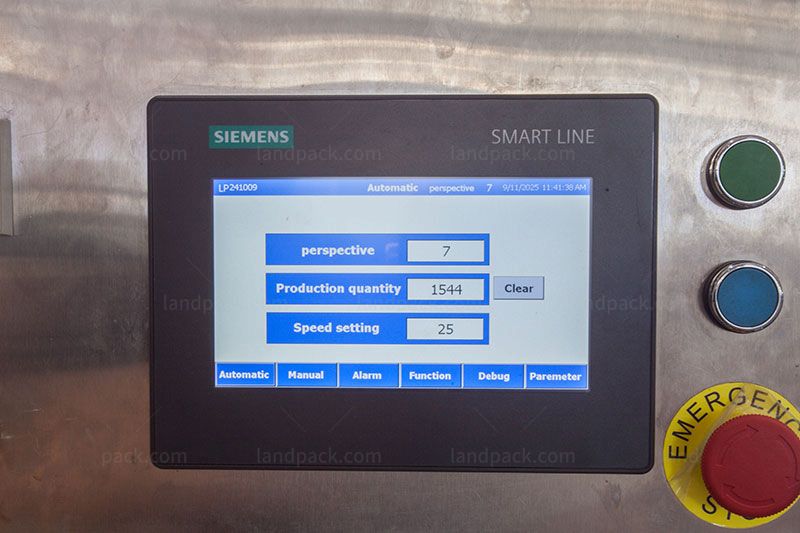

Control Panel User-friendly touch screen for easy operation and parameter setting. |  |

| Chain Conveyor Filler Ensures stable granule food transfer and accurate positioning. |

Piston Pump High-precision liquid dosing, suitable for sauces, jams, and liquids with small particles. |  |

| Double Bag Feeding Reliable suction and mechanical opening system for smooth bag handling. |

Double Bag Opening Reliable suction and mechanical opening system for smooth bag handling. |  |

| Double Liquid Filling Reliable suction and mechanical opening system for smooth bag handling. |

Double Granule Filling Efficient dosing of solid or granular products such as beans, meat cubes, or pickles. |  |

| Exhaust Air Removes excess air inside the pouch to extend shelf life and maintain product quality. |

Double Bag Sealing Strong and consistent sealing ensures freshness and prevents leakage. |  |

Get Price & More Detail