Pickled Cans Filling Machine | Automatic Fruit Cans Filling Seaming Coding Line

Model: Pickled Cans Filling Line

This automatic fruit canning filling line integrates container unscrambling, multihead weighing, solid and liquid filling, sealing, coding, and collection into one continuous system.

Application:

Engineered for fruit canning manufacturers, this system supports high-speed filling of fruit pieces followed by controlled syrup or juice dosing.

Application:

Engineered for fruit canning manufacturers, this system supports high-speed filling of fruit pieces followed by controlled syrup or juice dosing.

Package Type:

This fruit canning filling line is designed for a wide range of metal and rigid containers commonly used in food canning. It supports round tin cans, aluminum cans, and composite cans with standard diameters and heights. The system is compatible with easy-open lids and press-on caps, ensuring stable filling, sealing, and coding throughout continuous canning operations.

Suitable Products:

This fruit canning filling line is engineered for accurate solid-liquid portioning and continuous can sealing, making it suitable for a wide range of canned food products that require stable filling ratios and reliable closure performance.

Canned Fruits & Fruit Pieces: Peaches, pineapples, pears, mandarin segments, cherries, mango chunks, mixed fruits, and diced tropical fruits.

Fruit in Syrup & Juice: Fruits filled with light syrup, heavy syrup, natural fruit juice, flavored juice, or glucose-based soaking liquids.

Solid-Liquid Canned Foods: Fruit salads, dessert cups, cocktail fruits, and other food products combining solid pieces with liquid media that require consistent weight and visual presentation.

Workflow:

1. Cans Feeding: Empty cans are automatically organized and conveyed into the filling line, maintaining a stable and uninterrupted production flow.

2. Weighing: A high-accuracy weighing system precisely regulates the fill weight, ensuring consistent portions and improved operational efficiency.

3. Granule Filling: The pickle filling unit accurately doses solid or granular ingredients, making it well suited for pickled fruits and vegetable products.

4. Liquid Filling: Liquid components such as brine or sauce are added automatically to achieve dependable solid–liquid combination filling.

5. Cans Seaming: The can seaming module creates secure, leak-proof seams that help protect product quality and extend shelf life.

6. Cap Pressing: Caps are pressed firmly and evenly to strengthen sealing performance and enhance packaging safety.

7. Laser Printer: An integrated laser marking system applies production dates, batch codes, or traceability details directly onto each can.

8. Finished Product Output: Completed cans are smoothly transferred out of the line, ready for inspection, cartoning, or further packaging operations.

| Automatic Bottle Feeder | |

| Machine Model | LD-LP800N |

| Power Supply | 220V/110V, 50-60Hz, 200W |

| Turntable Diameter | 800mm |

| Suitable Bottle Diameter | 20-100mm |

| Suitable Bottle Height | 30-320mm |

| Working Speed | 40-60 bottles/min (depending on bottle size) |

| Package Size | 1230*1010*1260 mm |

| Gross Weight | 141kg |

| Automatic Grunale Filling Machine | |

| Model | LF-ZP-10 |

| Output | 20-30 bottles/min |

| Bottle diameter | Ф30mm-Ф135mm (customizable) |

| Bottle height | 40mm-200mm (customizable) |

| Power | 750W, 220V, 50Hz |

| Weight | 200kg |

| Automatic Liquid Pump Filling Machine | |

| Model | LD-YTZL4A |

| Filling head | 10 Heads |

| Air pressure | 0.5-0.8MPa |

| Liquid level accuracy | ±1mm |

| Viscosity range | <20Cps (static viscosity) |

| Working speed | 30-60 Bottles/Min |

| Machine size | About 1600*1150*1530mm |

| Machine weight | About 298kg |

| Package size | About 1660*1310*1670mm |

| Automatic Can Sealing Machine | |

| Number of sealed cans | 1 |

| Sealing speed | 15-24 bottles/min |

| Can sealing height | 50-200mm |

| Applicable bottle diameter | 50-126mm |

| Power | 0.55KW |

| Weight | 130KG |

| Size | 400*600*1450mm |

| Voltage | 220V, 50/60Hz |

| Automatic Plastic Lids Pressing Machine | |

| Seal Can diameter | φ40-φ130mm (can be customised) |

| Bottle's height | 60-300mm(can be customized) |

| Cap's height | 5-15mm |

| Speed | 30-50 Cans/min (can be customised) |

| Storage can cover | about 100pcs |

| Machine Size | 1900x800x1700 mm |

| Power | 220V/380V, 0.68KW |

| Air Pressure | 0.6MPa |

| Laser Printer | |

| Print range | 100*100mm |

| Positioning way | Infrared focusing |

| Focuslens | focal length 150mm |

| Speed | Max10000mm/s (can be customised) |

| Laser | fiber laser generator |

| Machine voltage | 220V (can be customised) |

| Machine size | 825*545*1425mm |

| Machine weight | 60kg |

Machine Key Components:

1. Bottle unscrambler

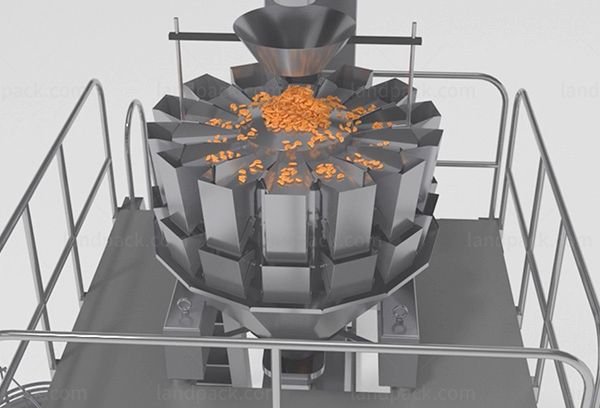

2. Multi Head Weight Weigher

3. Granule Filling Machine

4. Liquid Filling Machine

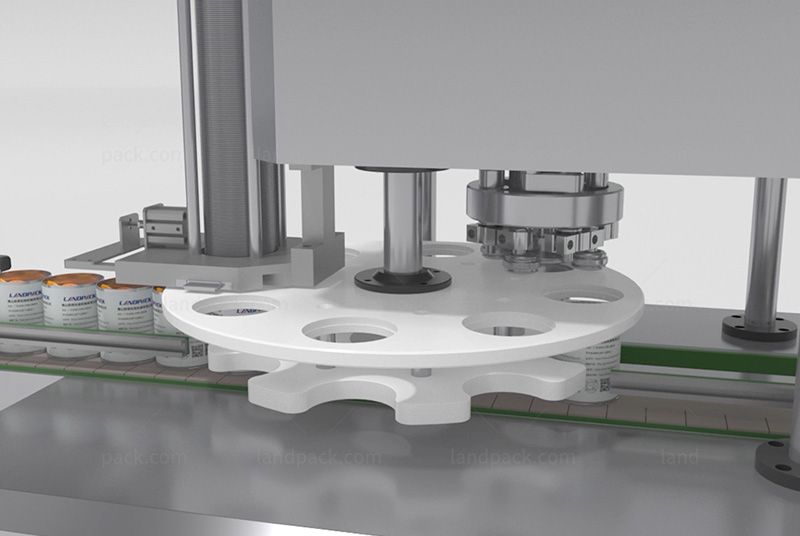

5. Seaming Machine

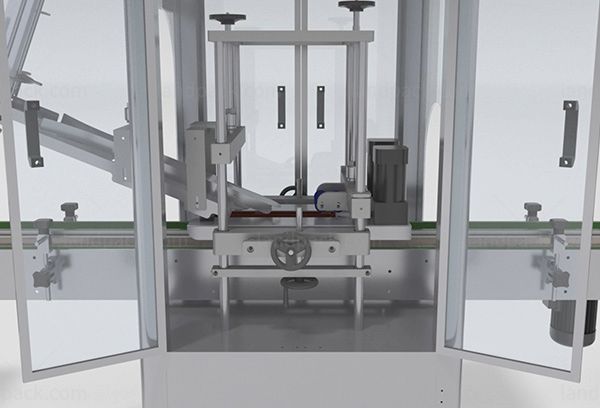

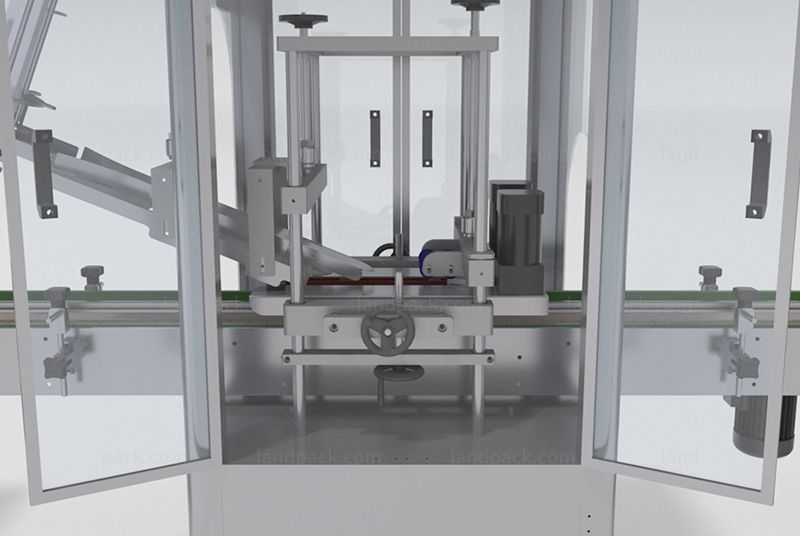

6. Caps Pressing Machine

7. Laser Printer

8. Collection Table

Feature:

Bottle Unscrambler Automatically arranges and delivers empty cans to the filling section in a smooth, continuous flow, reducing manual intervention and improving overall production efficiency. |  |

| Multi Head Weight Weigher The high-accuracy multi-head weighing unit precisely manages fill weights for solid products, ensuring uniform portions of pickled fruits, vegetables, and granular materials. |

Granule Filling Machine Engineered for handling solid and granular ingredients such as fruit chunks or vegetable pieces, the system provides fast and reliable filling performance. |  |

| Liquid Filling Machine Liquid filling modules accurately dispense brine, sauces, or other liquids into the cans, enabling clean and stable solid–liquid combination filling. |

Seaming Machine The can seaming system creates strong, leak-resistant seams that help preserve product quality and extend shelf life, making it ideal for canned and pickled foods. |  |

| Caps Pressing Machine The cap pressing mechanism applies consistent pressure to ensure secure closures, improving package integrity during transport and storage. |

Laser Printer A non-contact laser coding unit clearly and permanently marks production dates, batch codes, or QR codes on each can, supporting full product traceability. |  |

Get Price & More Detail