Automatic Pickles Packing Machine | Vertical Pouch Packing Machine

Model: LD-420BL

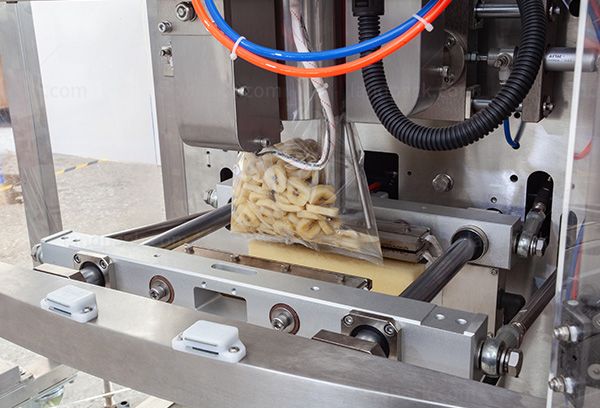

The LD-420BL vertical packaging machine is designed for combined solid and liquid packaging in one pouch. It integrates a chain plate elevator for solid products and a piston liquid filling system for sauces or brine.

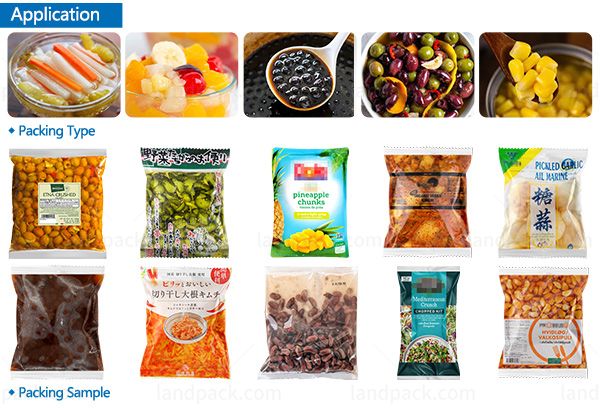

Application:

This packaging system is suitable for products that require both solid pieces and liquid filling in a single bag. The solid materials are gently conveyed by a chain plate elevator, while liquids are precisely dosed through a piston filler.

Application:

This vertical packing machine is engineered to package solid ingredients and liquid components together in a single pouch. It combines a chain-type elevator for handling solid materials with a piston-based liquid filling unit for sauces or brines. Through coordinated dosing and stable vertical sealing, the system ensures clean product separation, uniform fill accuracy, and dependable operation for mixed-product food packaging applications.

Package Type:

This vertical packaging system is compatible with pillow bags, three-side seal pouches, and four-side seal formats. Bag size parameters can be flexibly adjusted to suit different solid-to-liquid ratios, maintaining reliable sealing quality and a uniform package appearance for mixed-product packaging.

Suitable Products:

This vertical packaging machine is designed for combined solid and liquid packaging, integrating a chain-bucket elevator for granules and a piston filling system for liquids. It enables precise proportion control and stable sealing, making it ideal for products requiring both particulate and sauce or syrup in a single bag. Typical applications include:

1. Pickled & Preserved Foods: Kimchi, pickled vegetables, mixed pickles with brine, marinated radish, and fermented cabbage products.

2. Fruit & Sauce-Based Products: Fruit pieces with syrup, fruit cocktail packs, preserved fruits in juice, diced mango with syrup, and mixed fruit toppings.

3. Ready-to-Eat & Specialty Foods: Vegetable mixes with seasoning liquid, seasoned bean products, snack kits with sauce, and specialty condiment combinations.

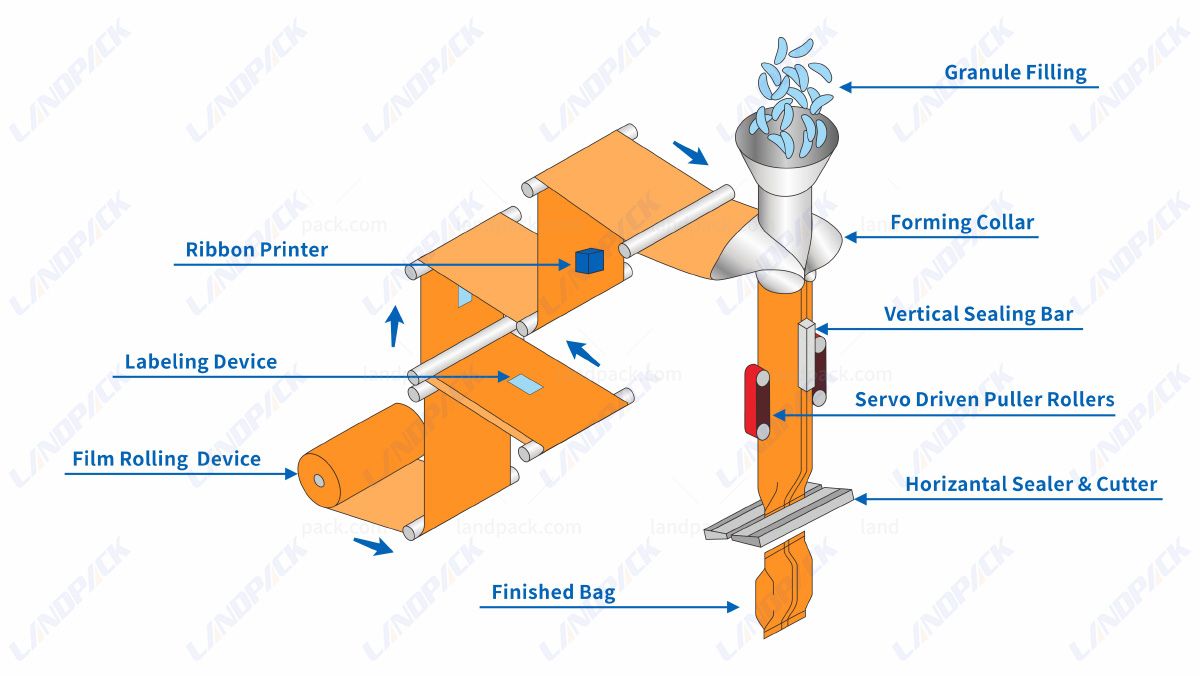

Workflow:

1. Granule Feeding: Solid materials are smoothly lifted by the chain-bucket elevator and guided into the forming system with stable, continuous feeding.

2. Liquid Dosing: The piston filling unit accurately dispenses liquid or sauce into the bag, synchronized with the granule filling process.

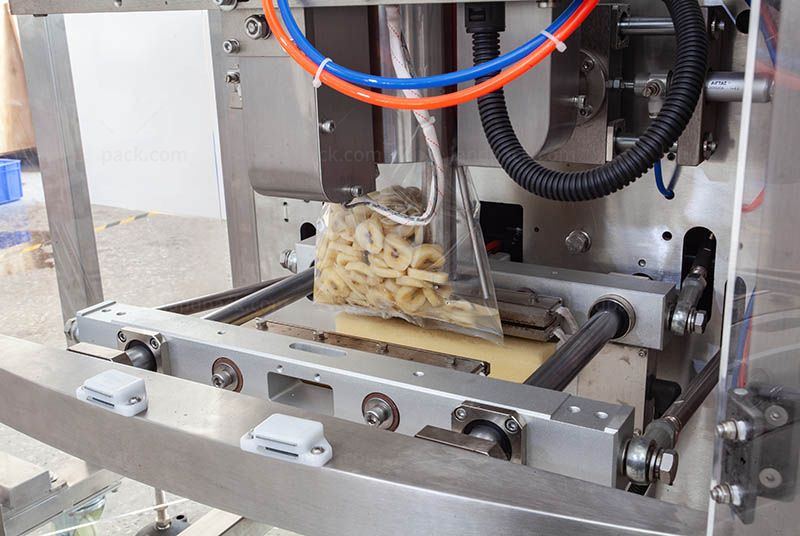

3. Bag Forming & Filling: Film is shaped into bags while solid and liquid components are filled in controlled proportions.

4. Sealing & Cutting: The filled bags are securely heat-sealed and precisely cut to ensure leak-free, consistent packages.

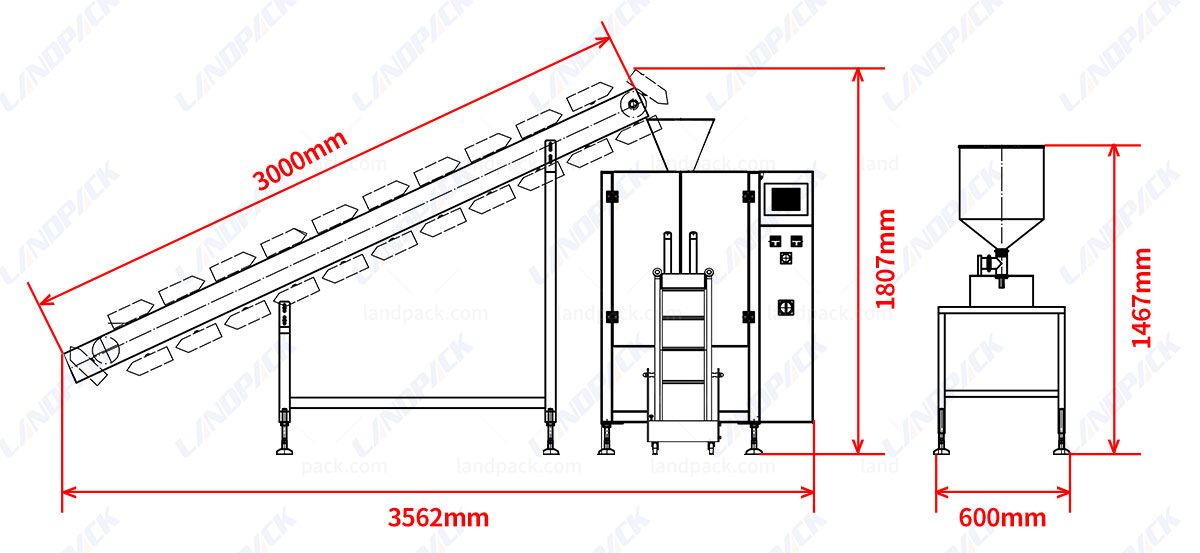

| Model | LD-420BL | LD-520BL | LD-620BL | LD-720BL |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 60-400mm | 60-450mm | 60-500mm |

| Bag Width | 60-200mm | 100-250mm | 65-300mm | 65-350mm |

| Film Roll Diameter | Max.600mm | Max.600mm | Max.600mm | Max.600mm |

| Pakaging Rate | 5-60 bags/min | 5-40 bags/min | 5-35 bags/min | 5-30 bags/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.620mm | 150-Max.720mm |

| Making bag volume | 1000ml | 2000ml | 3000ml | 5000ml |

| Power Supply | 220V, 50/60HZ, 3KW | 220V, 50/60HZ, 3KW | 220V, 50/60HZ, 3.2KW | 220V, 50/60HZ, 3.5KW |

| Machine Size | 1217*1015*1343 mm(L*W*H) | 1488*1080*1490 mm(L*W*H) | 1488*1180*1550 mm(L*W*H) | 1780*1350*2050 mm(L*W*H) |

Machine Key Components:

1. Chain Elevator

2. Packing Machine

3. Piston Pump

Feature:

Chain Conveyor Ensures stable and hygienic transfer of granular materials with minimal spillage. |  |

| Emergency Stop Integrated safety button allows immediate shutdown to protect operators and equipment. |

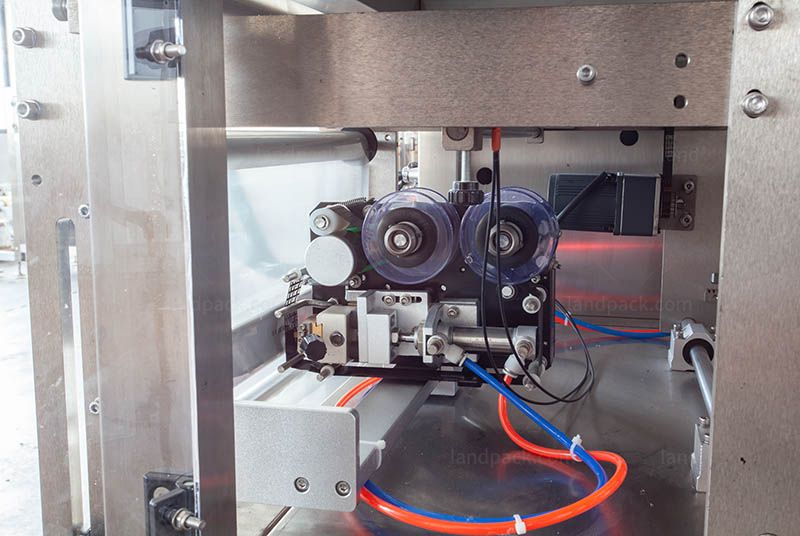

Coding Machine Prints clear production dates and batch codes in real time for easy traceability. |  |

| Liquid Pump Delivers precise, stable liquid dosing, suitable for sauces, syrups, and brine-based products. |

Sealing and Cutting Station Provides strong, consistent seals and clean cuts for reliable package integrity. |  |

Get Price & More Detail