Automatic Powder Canister Tins Filling Production Line With UV Sterilization

Model: LD-PA01U

Application:

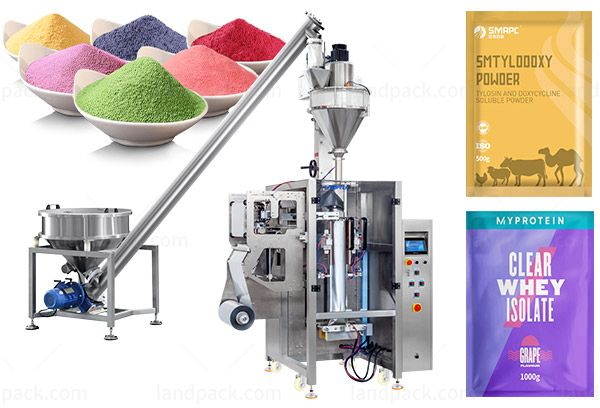

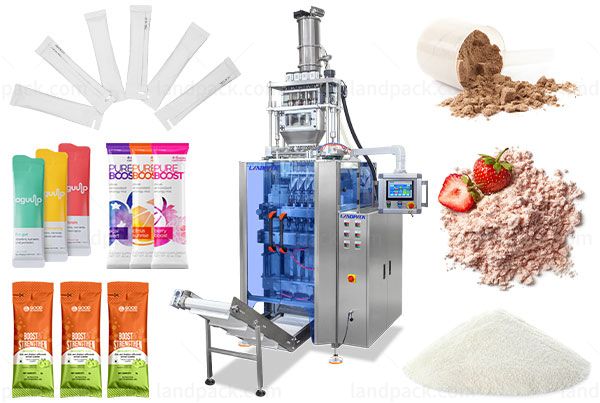

Automatic Powder Canister Tins Filling Production Line With UV Sterilization , automatic dropping spoon and nitrogen filling functions, It is suitable for many kinds of powder such as: milk powder, protein powder, medicine powder, coffee powder, collagen powder, flour, rice powder, seasoning powder, chemical powder, organic plant powder, soy flour etc.

Application:

Automatic Powder Canister Tins Filling Production Line With UV Sterilization , automatic dropping spoon and nitrogen filling functions, It is suitable for many kinds of powder such as: milk powder, protein powder, medicine powder, coffee powder, collagen powder, flour, rice powder, seasoning powder, chemical powder, organic plant powder, soy flour etc.

Packaging Type: Cans, Bottles, Tins, PET, glass bottle, tinplate Other.

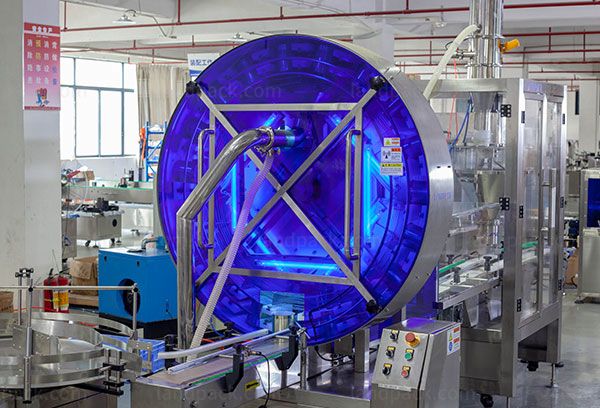

Packaging Material: Glass, Metal, Paper, Plastic, Wood, Other.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

| Product Name | Automatic Powder Filling Line |

| Model | LD-PAF01 |

| Filling Range | 100-2000g (Customizable) |

| Filling Speed | 10-25 bottle/min |

| Measurement accuracy | ±1% |

Power | 4.5 KW |

| Working power supply | 220V、50Hz |

| Working pressure | 0.6-0.8MPa |

| Weight | 500kg |

| Size | L11782*W3465.09*H2523.52(mm) |

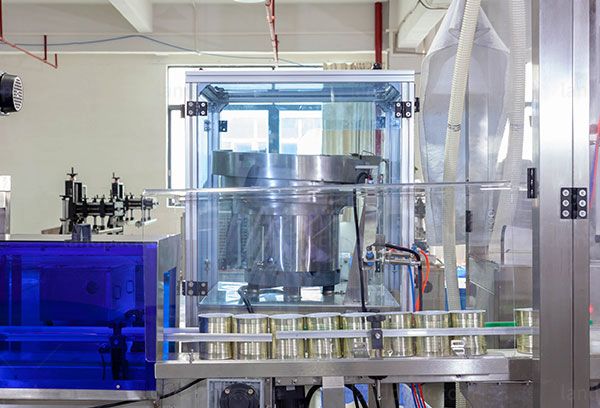

1.Automatic two-head Auger type metering/filling system works with the automatic capping machine;

2.Able to work with the double star wheels for bottle/can conveying & positioning system to perform the filling operation;

3.Conveyor is mounted a precision splitter to perform the intermittent movement for bottle/can to achieve the accurate positioning function;

4.Transmission system of the filling machine is driven by Japan Panasonic servo motor for high accuracy and stability;

5.Auto bottle/can positioning, lifting and vibrating, filling system is able to stop filling automatically when there's no bottle, and when bottle jammed occurs, the machine (system) will also stop automatically;

6.10 sets of memory modules for memorizing different kinds of products and filling weights;

7. This line is especially suitable for canned milk powder, protein powder, nutrition powder and so on, equipped with UV sterilization and purging;

8. Drop the spoon automatically;

9. The filling machine adopts the weighing filling measurement, the precision is higher than the screw measurement;

10. Vacuum sealed tank filled with nitrogen to extend the shelf life of products;

11. This line is especially suitable for canned milk powder, protein powder, nutrition powder, etc., equipped with UV sterilization and purging;

12. Automatic spoon drop;

13. The filling machine adopts bottom weighing filling measurement, which has higher precision than screw measurement;

14. Vacuum sealed cans filled with nitrogen to extend product shelf life.

We have many different kinds of powder customer packing case videos, please feel free to contact us to obtain your product packing case videos.

Get Price & More Detail