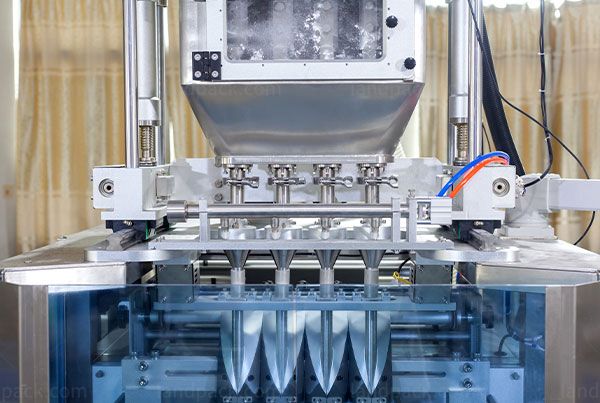

Automatic 4 Lanes Tea Powder Medical Powder Stick Packaging Machine

Model: LDBk560D-4

Application:

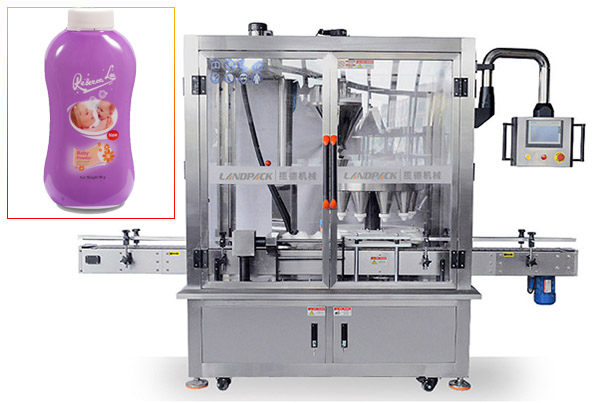

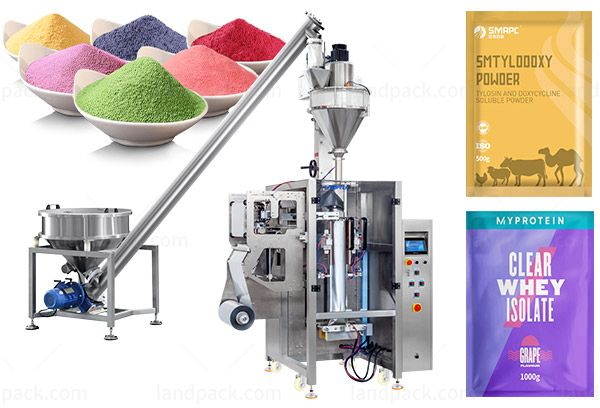

High accuracy powder multi track packing machine, it is suitable for many kinds of powder products, such as tea powder, medical powder, chemical powder, flour, milk powder, coffee powder, glucose, medical powder, nutrition powder, etc.

Application:

Automatic 4 lanes tea powder medical powder stick packaging machine, it can automatically complete packaging, sealing, cutting and other operations, reducing manual intervention.

Examples:

Tea powder, medical powder, chemical powder, flour, milk powder, coffee powder, glucose, medical powder, protein powder, nutrition powder, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examples:

| Model | LD-280BF |

| Production capacity | 140-210 bags/min |

| Diameter of the film roll | Maximum 300mm |

| Packaging film width | 17-30 mm |

| Outer bag size | The longest 180mm widest 30mm product packaging |

| Air pressure | 0.5-0.7Mpa |

| Machine noise | Less than 80db(A)decibel |

| Heating power | 3.5 Kw |

| Total weight of the machine | 350KG |

| Machine size | 1385mm*918mm*2005mm |

1. High production efficiency, 4 lanes speed can reach 100-150 packets per minute, improve production capacity and save manpower.

2. High degree of automation: filling, feeding, printing batch number, cutting easy to tear, finished bag output is completed in one time, quick and convenient adjustment.

3. Servo motor system control, accurate measurement, accurate film drawing, and film feeding.

4. Vacuum pump feeding is more sanitary.

5. Easy to use, do not need to switch different modes and frequent debugging, all parameters set before the factory, only need to set simple parameters on the screen can be used.

Work Flow:

1. Vacuum feeder is more hygienic in conveying materials.

2. Air shaft roll film device.

3. Date coding.

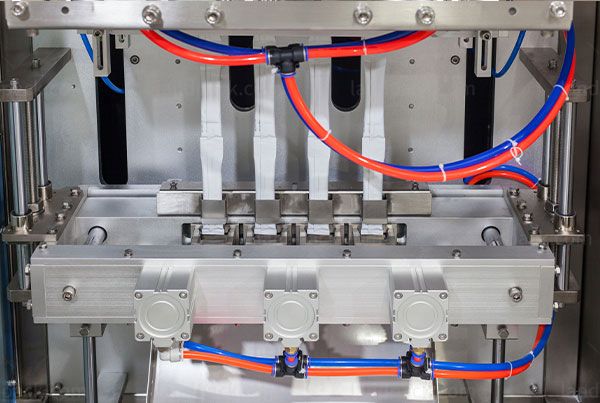

4. Screw the metering device with an anti-leaking device.

5. Pulling film is under servo motor driven.

6. Pull packing film and sealing.

7. Feed powder into a sachet.

8. Cutting and outputting the finished product.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail