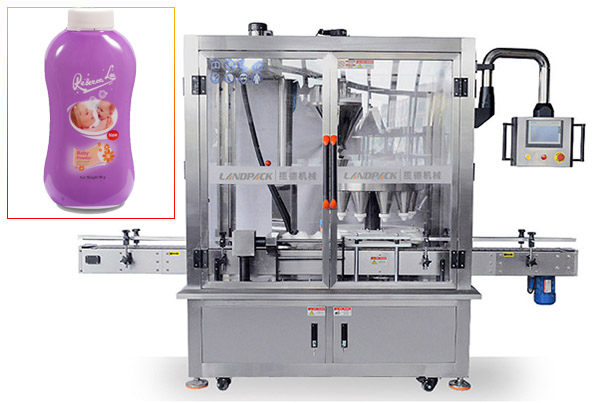

Automatic Powder Bottle Mixing Filling Capping Labeling Line With Dust Collector

Model: LF-LX02W

Application:

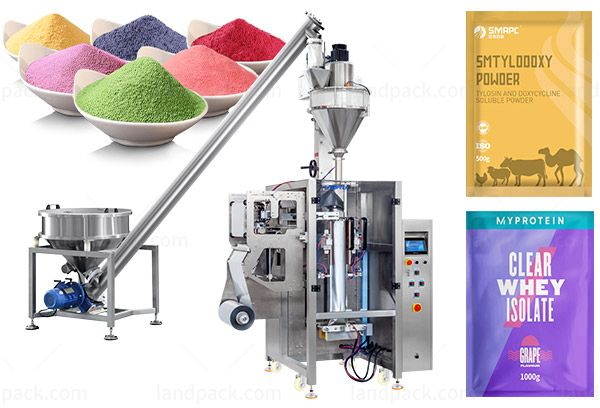

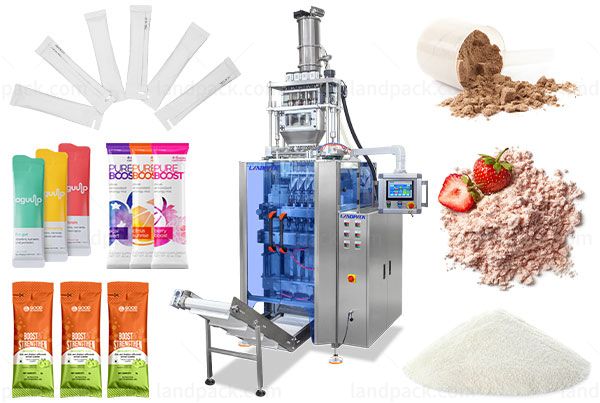

It is suitable for varise of powder products packing, Through the replacement of screw attachments, powder materials can be packaged in various packing specifications such as milk powder, nutritional powder, protein powder, spice, coffee, flour, pesticides, ect.

Application:

Automatic Powder Bottle Mixing Filling Capping Labeling Line With Dust Collector (LF-LX02W), It is suitable for varise of powder products packing, Through the replacement of screw attachments, powder materials can be packaged in various packing specifications such as milk powder, nutritional powder, protein powder, spice, coffee, flour, pesticides, ect.

Packaging Type: Cans, Bottles, Tins, PET, glass bottle, tinplate.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Automatic Powder Weighing Filling Capping And Labeling Machine | ||||

Model | LF-LX02W | |||

Filling Weight | 10-5000g(customizable) | |||

Bottle diameter | Φ30-Φ140mm(customizable) | |||

Bottle height | 50mm-200mm(customizable) | |||

Power | 220V/380V/50/60 HZ | |||

Packing speed | 30-70bottle/min | |||

Measurement accuracy | ≤500g,≤±1%;>500g,≤±0.5% (Varies due to the characteristics of the material) | |||

Powder | 2.5KW | |||

Machine Weight | 750KG | |||

Dimensions (mm) | 4400*1.2*1800(L*W*H mm) | |||

1.The entire machine is made of stainless steel, and it is especially suitable for GMP certification, food hygiene certification, and anti-corrosion chemical products.

2.Touch screen man-machine interface,operation is stable.The weight of the package can be adjusted steplessly at any time, and the working status can be changed at any time.

3.Filling adopts servo motor,with the advantages of accurate positioning, high precision, high speed, large torque, long life,speed can be set, good stability and so on.

4.Double-head cutting, fast speed and high production capacity.

5. Stirring uses Taiwan geared motor: low noise, long life, and lifetime maintenance free.

6.Designed as feedback proportion tracking system, it overcomes the disadvantages of weight changes due to changes in the proportion of materials.

7.The fully sealed air-resistance glass stainless steel side-opening compound material hopper provides clear visibility of materials and dust without leaking. The suction device is installed at the outlet to 8.Twin-screw feeder with a mixing bucket, which can stir the powder evenly. Convenient measurement

9. Replacement screw accessories can adapt to a variety of materials from ultra-fine powder to large particles.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail