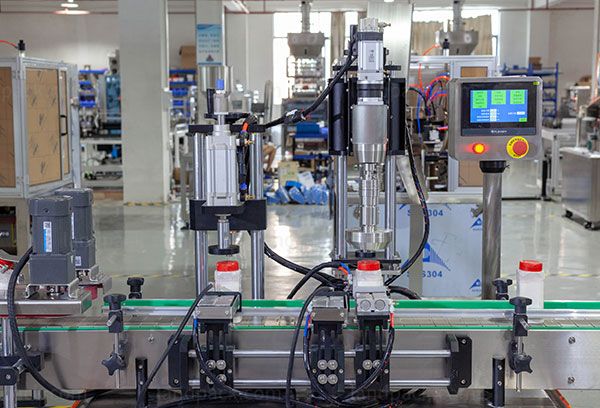

Automatic Powder Bottle Filling Weighing Capping Sealing And Labeling Line

Model: LF-LX-01D

Application:

It is used for automatic measuring, filling, weighing, sealing, labeling and coding of various powder products.

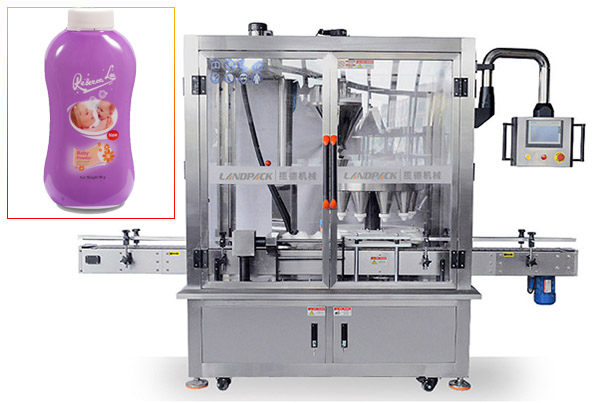

Applicable bottle material: PET, glass bottle, tinplate, etc.

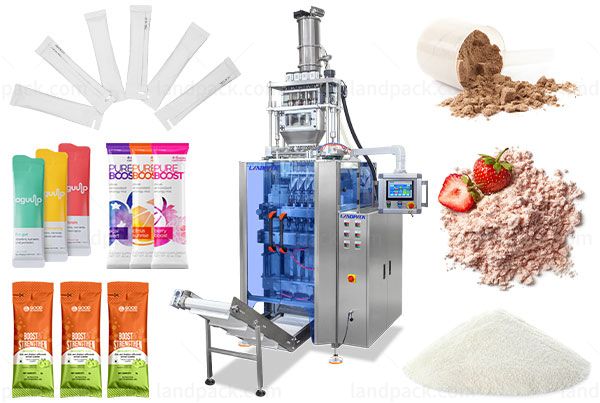

Applicable materials: milk powder, coffee powder, protein powder, peptide powder, nutrition powder, chemical powder, etc.

Application:

Automatic Powder Bottle Filling Weighing Capping Sealing And Labeling Line(LF-LX-01D), It is suitable for filling powdered materials such as milk powder, nutrition powder, protein powder, coffee powder, peptide powder, chemical powder, etc.

Packaging Type: Cans, Bottles, Tins, PET, glass bottle, tinplate.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Name | Automatic powder bottle production line |

Filling weight | According to customer requirement |

Power supply | 3 phase 380V 50Hz |

Compressed air consumption | 6kg/cm² |

Air consumption | 1.45m'/min |

Bottle material | 307#/401#/502#/300#/PET,glass bottle, tinplate |

Filling specification | Changing the mold of no defective filling machine and nitrogen filling & filling machine can canning products of various specifications |

Packing speed | 15-55 bags/min |

Measurement accuracy | ≤ ± 0.5% |

1. This production line is configured according to the conv entional bottling process, and the

whole production process is highly automated, which conforms to the Chinese GMP hygiene standard;

2. The supporting machines of this production line are all stainless steel except the materials indicated. All the machine structures are selected and designed according to the food hygiene standards;

3. The container materials in contact with the materials are food-grade SUS304;

4. The cleaning structure is connected with detachable parts, so as to ensure the sanitation and convenience of handling when transferring or chang ing products;

5. The whole line is fully equipped, saving labor;

6. Water-cooled aluminum foil sealing machine, the sealing effect is better than air-cooled, and the machine is more durable;

7. The labeling adopts belt rolling, and the three sides of the square bottle are shared with the round bottle.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail