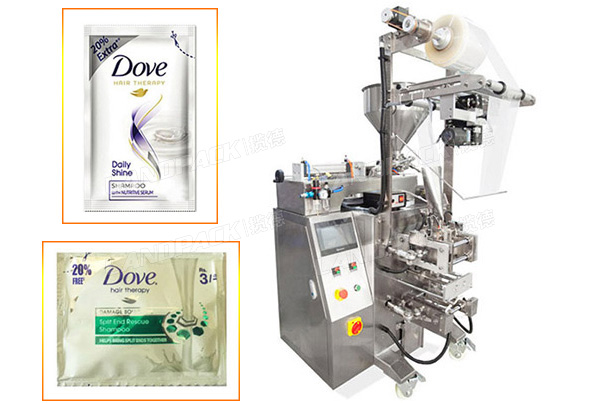

Automatic Horizontal Different Shampoo Premade Twin Pouch Filling Packing Machine

Model: GP-210L

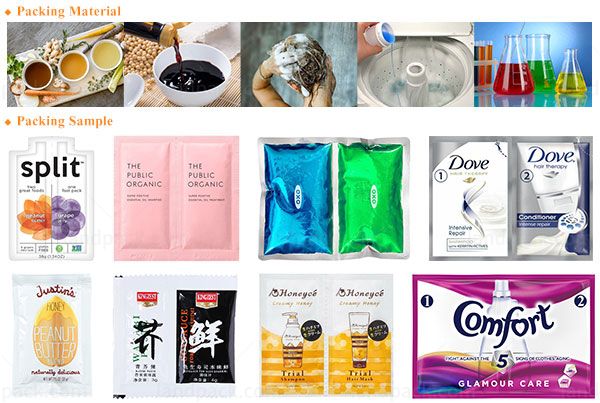

Application:

Suitable for packing liquid standing bags, pre-made bags, zipper bags packaging, such as shampoo, juice, cream, jam, laundry detergent, hand soap, sauces, honey, milk, etc.

Application:

Automatic horizontal different shampoo premade twin pouch filling packing machine(GP-210L), suitable for packing liquid standing bags, pre-made bags, zipper bags packaging.

Examples:

Shampoo, juice, cream, jam, laundry detergent, hand soap, sauces, honey, milk, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

Feature

1.Rapidly change bag specification in one-click antomaticadjustment.

2.Single shaft and the GAM design , faster packing apeed,more stable operation , easier maintence and defective rate reducting.

3.Modular heating ,temperature control is more accurate , heating fault has alarm prompt.

4.Adcanced design idea, reduce the material loss, ensure the stability of operation, extend the operation life.

5.Simple and convenient operation, adopt the adcanced PLC + POD(touchscreen) electric control system and man-machine interface.

Work Flow:

1.Vertical bag giving station.

2.Ribbon coding.

3.Opening bag.

4.Double piston pump with Double filler.

5.Filling different material into twin pack at the same time.

6.Sealing.

7.Outlet.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail