Shampoo Bottle Filling Machine | Hair Oil Filling Line With Capping Labeling Shrinking Machine

Liquid Tracking Filling Line

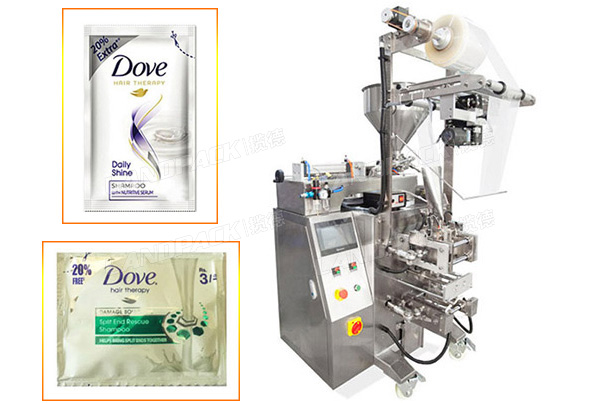

The Automatic Shampoo Hair Oil Filling Line is a mobile, high-efficiency liquid filling solution specifically engineered for the personal care and cosmetic sectors.

Application:

This versatile filling line is ideal for a wide spectrum of liquid and moderately viscous products, including: shampoo, hair conditioner, body lotion, hair oils, liquid soap, and hand sanitizer.

Application:

This versatile filling line is ideal for a wide spectrum of liquid and moderately viscous products.

Package Type:

It offers exceptional versatility in container handling, effortlessly managing a wide range of packaging types, including glass and plastic bottles in various geometries such as oval, round, flat, and square shapes. Furthermore, the system is compatible with multiple closure styles, accommodating screw caps, flip caps, and pump caps. It perfectly handles the filling and packaging of essential liquids like shampoo, body lotions, hair oils, detergents, and disinfectants, ensuring product presentation is flawless.

Suitable Products:

This versatile filling line is ideal for a wide spectrum of liquid and moderately viscous products, including:

Personal Care/Cosmetics: Shampoo, hair conditioner, body lotion, hair oils, liquid soap, and hand sanitizer.

Household Chemicals: Laundry detergent, dish soap, fabric softener, and general-purpose disinfectants.

Food & Beverage: Various edible oils, syrups, sauces, and non-carbonated drinks.

The system is engineered to handle liquids of different viscosities, ensuring smooth and precise filling across diverse product categories.

Workflow:

1. Bottle Unscrambler - Arranges and feeds bottles onto the line automatically.

2. Filling Machine - 4 Head Tracking Filler accurately fills hair oil or shampoo.

3. Caps feeder - Sorts and supplies caps automatically.

4. Capping machine - Tightens caps tightly to prevent leakage.

5. Inkjet printer - Prints batch codes and expiration dates.

6. Labeling machine - Applies labels neatly, precisely and accurately.

7. Shrink-Sleeve Machine - Shrinks sleeves to give a finished, clean look.

| Liquid Tracking Filling Machine | |||

| Number of filling nozzles | 2 Nozzle | 4 Nozzle | 8 Nozzle |

| Filling range | 1000-5000ml | ||

| Filling speed | ≤1800 bph | ≤2500 bph | ≤6000 bph |

| Measurement accuracy | ≤±1% | ||

| Power | 3.2KW | 7.2KW | 9.8KW |

| Voltage | AC380V 50-60HZ | ||

| Air pressure | 0.5 - 0.7 Mpa | ||

| Dimension | 1800*1500*2200mm | 2200*1600*2200mm | 4600*1800*2200mm |

| Weight | About 600kg | About 1000kg | About 2000kg |

| Automatic Bottle Capping Machine | |||

| Model | LFX-JX-01 (Four wheel capping | LFX-GS-150 (Eight wheel capping) | LFX-GS-250 (Six wheel capping) |

| Capacity | 20-50 bottles/min | 40-100 bottles/min | 30-80 bottles/min |

| Bottle cap diameter | Ф22mm-Ф80mm | Ф18mm-Ф80mm | Ф18mm-Ф80mm |

| Bottle diameter | Ф35mm-Ф140mm | Ф35mm-Ф140mm | Ф35mm-Ф140mm |

| Bottle sealing height | 38mm-300mm | 38mm-300mm | 38mm-300mm |

| Power | 1.5KW | 2KW | 1.5KW |

| Voltage | 220V, 50HZ | 220V, 50HZ | 220V, 50HZ |

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.5-0.7Mpa |

| Weight | 250kg | 350kg | 300kg |

| Dimensions | H3000*W800*L1600 mm | H3120*W1544*L2122 mm | H3100*W1244*L2122 mm |

| Automatic Labeling Machine | |||

| Model | LFT-SM-200C(double heads labeling) | LFT-SM-100C(Single heads labeling) | |

| Labeling speed | 10-40 bottles/min | 5-20 bottles/min | |

| Labeling accuracy | ±1mm | ±1mm | |

| Label maximum width | 200mm (Could be customized) | 150mm(Could be customized) | |

| Size of the object being attached | Height≤400mm; Thickness≤100mm | ||

| Label lD | Ф76.2mm | Ф25.4mm | |

| Label OD | MaxФ330mm | MaxФ230mm | |

| Voltage | 220V, 50HZ | 220V, 50HZ | |

| Power | 3.5KW | 2.5KW | |

| Weight | 500kg | 400kg | |

| Dimension | L3002*W1478*H1810mm | L2950*W1400*H1810mm | |

| Shrink Wrapping Machine | |||

| Voltage | Sleeve machine 220V can be customized, the shrink machine must be 380V | ||

| Power | 1.3KW/18KW | ||

| Sleeve machine packing size | Max 420*330*330mm, Min 250*60*60mm | ||

| Packing speed | 0-6 pieces/min | ||

| Tunnel size | 1500*600*400 mm | ||

| Tunnel out dimension | 2500*850*1520 mm | ||

| Sleeve out dimension | 1500*600*402 mm | ||

Machine Key Components:

1. Bottle unscrambler

2. 4 Head Tracking Filling Machine

3. Capping Machine (with Caps Feeder)

4. Inkjet Printer

5. Labeling Machine

6. Sleeve Shrink Packing Machine

Feature:

Bottle Unscrambler The bottle feeder automatically feeds the bottles in an upright position onto the conveyor, ensuring a smooth and continuous supply of bottles for the filling procedure. Ideal for a variety of bottle shapes and materials. |  |

| 4-Head Tracking Filling Machine The tracking nozzles follow the moving bottles to ensure precise, drip-free filling. Ideal for viscous liquids like hair oils, conditioners, and shampoo. |

Caps Feeder Automatically sorts and delivers caps to the capping station, maintaining a steady cap supply and minimizing manual operation. |  |

| Capping Machine The cap can be tightened on different bottles with the same consistency and security. The torque can be adjusted to prevent overtightening or leakage. |

Inkjet Printer Printing clear batch codes, dates or logos onto bottle surfaces improves product traceability and control. |  |

| Labeling Machine Apply self-adhesive labelling accurately to round, square or flat bottles. This will ensure a professional look and a strong adhesive. |

Sleeve Shrink Packing Machine Automatically applies shrink sleeves to bottles and passes them through a heated tunnel to ensure wrinkle-free, tight labeling. This enhances product protection and brand appearance. |  |

Get Price & More Detail