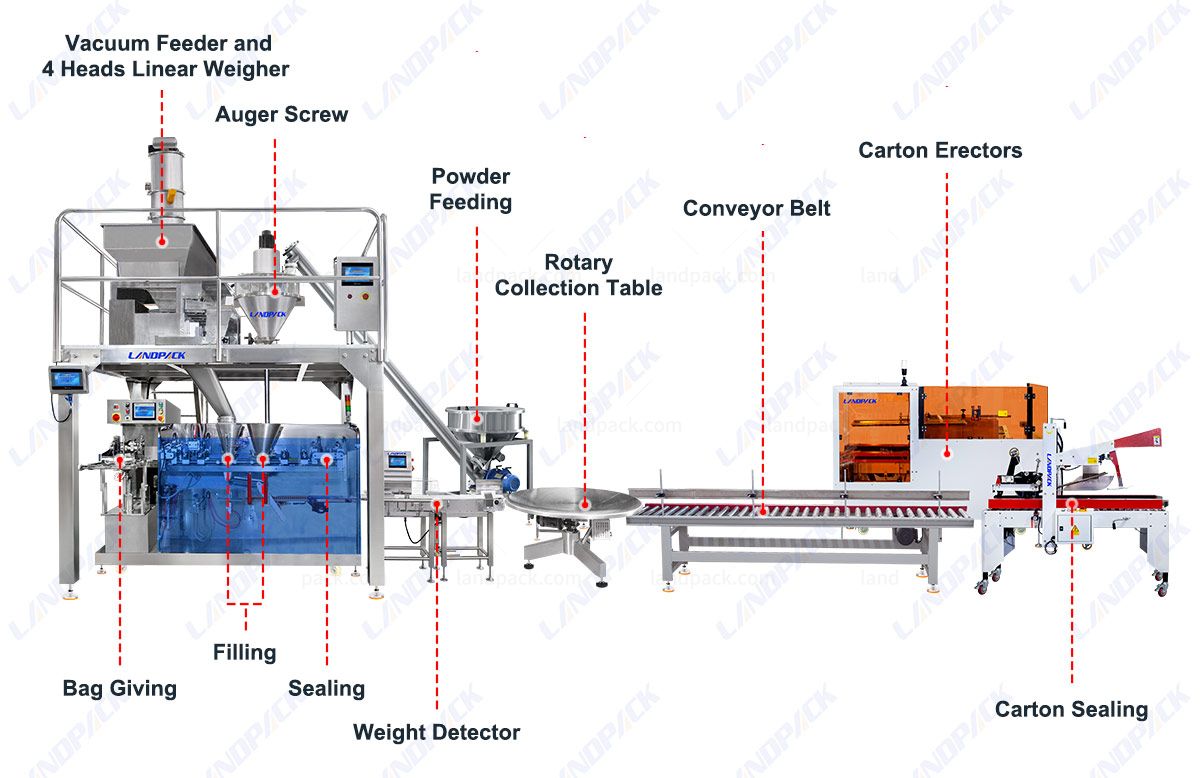

Automated Horizontal Premade Pouch Spice Packaging Line With Case Packer

Model: LDSP-260AS

This automated system precisely weighs and fills powders using a 4-head linear weigher. The horizontal premade pouch packing machine then seals the premade pouches, seamlessly integrating with a case packer and sealer for a complete, streamlined packaging line.

Application:

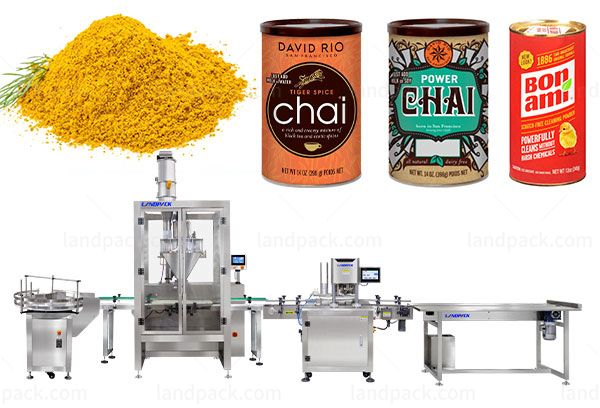

Perfect for packaging granular and fine-particle products. This machine is ideal for items like sugar, salt, coffee grounds, seeds, spices, MSG, detergents, and various pharmaceutical or chemical granules.

What is a Horizontal Premade Pouch Packaging Line?

This automated system precisely weighs and fills powders using a 4-head linear weigher. The horizontal premade pouch packing machine then seals the premade pouches, seamlessly integrating with a case packer and sealer for a complete, streamlined packaging line.

Application:

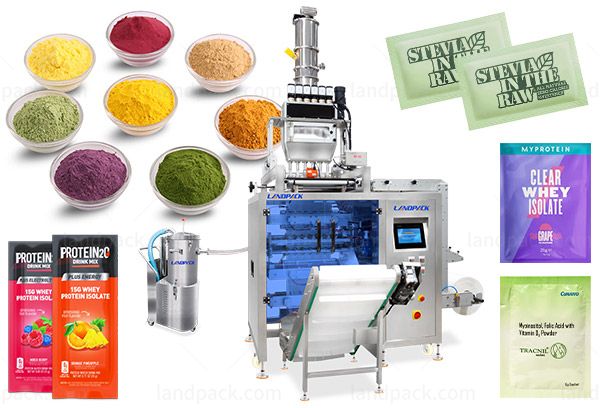

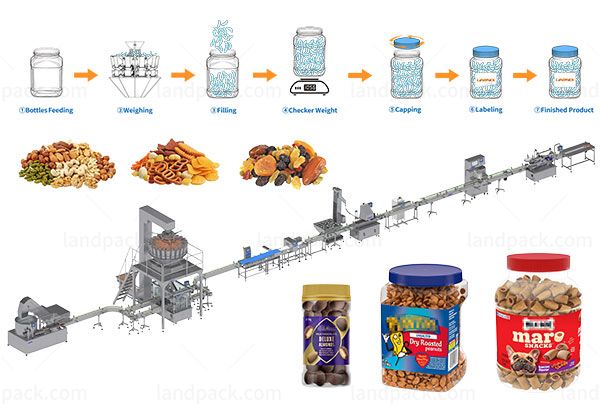

The Horizontal Premade Pouch Packing Machine Line with Carton Erector and Sealer is widely used for packing different types of granule and powder material, ensuring efficient pouch packaging and secondary carton packaging. It is suitable for:

- Powder Seasonings:

Curry powder, chili powder, pepper powder, five-spice powder, and other spice blends.

- Granule Seasonings:

Salt granules, sugar granules, chicken essence granules, sesame seeds, and other granular condiments.

- Other Food Ingredients:

Coffee powder, baking soda, starch powder, instant drink powder, and similar powdered or granulated raw materials.

Package Type:

It is compatible with various premade pouch styles, including stand-up pouches, flat pouches, M-shape gusset pouches, and Doypacks, which are ideal for packaging powders, granules, and other food or non-food products.

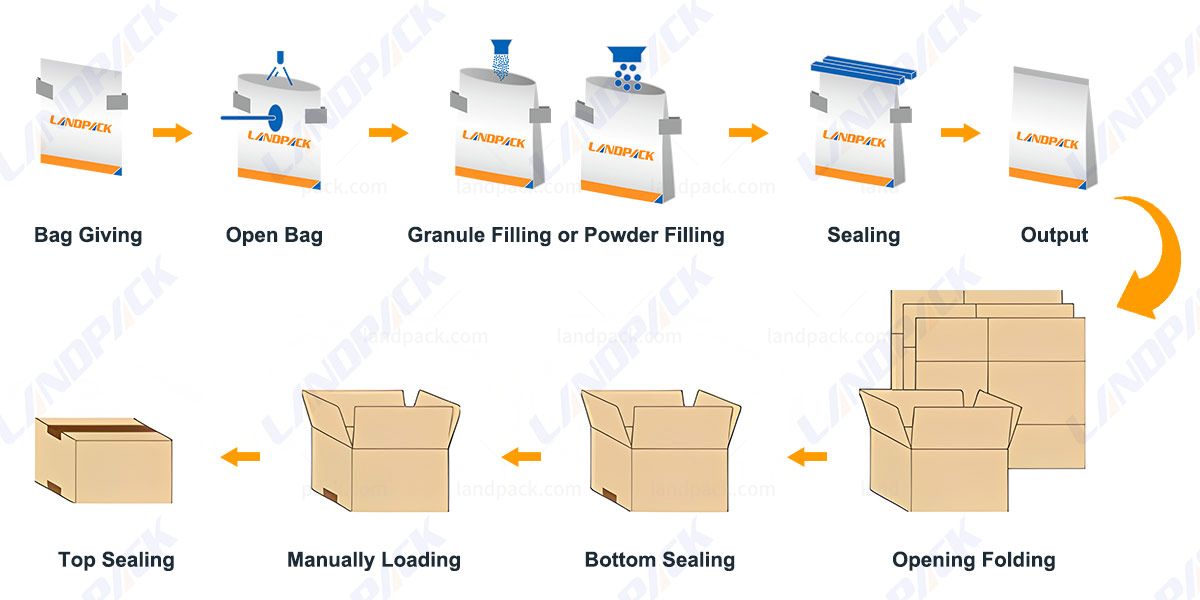

Process Workflow:

Vacuum Material Transfer System – Product is automatically and cleanly conveyed from the storage container to the dosing unit.

Multi-Head Dosing Unit (e.g., 4 Heads Linear Weigher) – Precisely measures and dispenses the required product mass with high speed.

Powder Metering Device (e.g., Auger Filler) – Ensures consistent and non-drip volumetric filling of fine powders.

Pouch Presentation – Automatically feeds the pre-formed bags into the gripping system of the machine.

Coding and Marking – Applies the production date, expiration date, or lot number directly onto the pouch surface.

Pouch Preparation – The bag is smoothly gripped and opened at the top, preparing it to receive the product.

Product Discharge – The pre-measured contents are accurately dropped into the now-open pouch.

Internal Cleaning/De-dusting – A mechanism to vacuum or brush away residual dust or product particles from the sealing area.

Secure Closure – Applies heat and pressure to hermetically seal the top of the pouch, preserving freshness.

Final Pouch Ejection – The completed, sealed pouches are smoothly released from the machine.

Check Weigher – An in-line verification step that inspects each pouch to confirm it falls within the specified weight tolerance.

Indexing and Collection System (e.g., Rotary Collection Table) – Organizes and accumulates the finalized pouches for further handling or transfer.

Carton Forming – Flat cardboard blanks are automatically erected and opened into three-dimensional boxes.

Carton Closure – The filled cartons are securely sealed, typically with tape or hot glue, for secondary packaging and distribution.

| Horizontal Pouch Packing Machine | |||||

| Type | LDSP-140 | LDSP-160 | LDSP-210 | LDSP-260 | |

| Bag Type | 3-side, 4 side sealing bag, doypack, box pouch, zipper pouch, stand up pouch, stand up pouch with hole, kraft paper bag, side gusset bag, etc. | ||||

| Bag Size | 110-230mm*80-160mm (L*W) | 110-230mm*80-160mm (L*W) | 110-320mm/100-210mm (L*W) | 160-380mm*140-260mm (L*W) | |

| Filling Range | 20g-500g | 20g-1kg | 20g-1kg | 20g-1kg | |

| Packing Speed | 20-45 bags/min | 20-50 bags/min | 20-50 bags/min | 20-40 bags/min | |

| Machine weight | 800KG | 900KG | 900KG | 900KG | |

| Total Power | 2.5KW | 2.5KW | 2.5KW | 2.5KW | |

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | |

| Weight Detector | |||||

| Model | LD10 | LD100 | LD201 | LD401 | LD1000 |

| Weight Range | 10-99g | 100-200g | 201-400g | 401-999g | 1000-10000g |

| Rate | 65 bags/min | 60 bags/min | 50 bags/min | 45 bags/min | 40 bags/min |

| Precision | ±0.5g | ±1g | |||

| Minimum scale | 0.1g | ||||

| Predesign pattern | 10 kinds | ||||

| Size | 1050*681*1260 | ||||

| Voltage | 220V | ||||

| Power | 300W | ||||

| Carton Erecting Machine | |||||

| Carton Opening Speed | 10-12 cartons/min | ||||

| Carton Size Range | L270-450×W150-400×H100-400mm(Min and Max cannot exist at the same time) | ||||

| Power Supply | 220V 50/60Hz 1 Phase | ||||

| Power | 240W | ||||

| Adhesive Tape Width | 48/60/75mm | ||||

| Carton Storage Quantity | 80-100pcs (800-1000mm) | ||||

| Air Consumption | 450NL/min | ||||

| Air Compressing | 6kg/cm³ | ||||

| Discharge table height | 600+30 mm | ||||

| Machine Size | L2100*W2100*H1450mm | ||||

| Machine Weight | 450kg | ||||

| Carton Box Case Sealer | |||||

| Voltage | 220V 60HZ | ||||

| Table Height | 620-900mm | ||||

| Tape | W48-79mm | ||||

| Carton Size | L200-600W*150-500*H150-500mm | ||||

| Machine Weight | 165kg | ||||

Machine Key Components:

* Vacuum Feeder and 4 Heads Linear Weigher

* Auger Screw

* Horizontal Pouch Packing Machine

* Weight Detector

* Rotary Collection Table

* Conveyor Belt

* Carton Erector

* Carton Sealer

Vacuum Feeder Efficiently transports powder or granular material with minimal spillage, ensuring consistent feeding for precise packing. |  |

| 4 Heads Linear Weigher Multi-head weighing guarantees speed and accuracy. It is ideal for fine powders and bulk material. |

Auger Screw Delivers powder consistently and precisely into pouches, making it less wasteful and ensuring uniform filling. |  |

| Powder Feeding Smooth and continuous feeding system designed for delicate or free-flowing powders. |

Horizontal Pouch Packing Machine Forms, fills and seals pouches with one easy process, ideal for different types of pouches. |  |

| Weight Detector Automatically checks the pouch's weight to make sure it's in compliance with the specifications, thus reducing mistakes. |

Rotary Collection Table Neatly collects completed pouches ready for packing downstream or for inspection. |  |

| Conveyor Belt Effectively moves pouches between machines while maintaining the smooth flow of production. |

Carton Erector Creates fast-forming cartons to accept pouches, increasing the effectiveness of packaging. |  |

| Carton Seale Seals cartons securely for transport and storage, completing the end-to-end packing process.r |

Get Price & More Detail