Spice Filling Machine | Powder Bottle Filling Capping and Labeling Line

Model: Powder Filling Capping and Labeling Line

Improve your seasoning production efficiency with a high-speed spice filling system designed for reliable performance. Operating at up to 40 bottles per minute, this all-in-one powder filling solution accurately handles everything from fine chili powders to blended and granulated spices with consistent, high-quality results.

Application:

This versatile bottle filling line is compatible with both glass jars and PET bottles, integrating accurate dosing with automatic capping and marking functions.

Application:

Boost your seasoning production with a high-speed spice filling system designed for efficiency and consistency. With an output of up to 40 bottles per minute, this integrated powder filling solution accurately processes a wide range of products, from fine chili powders to granulated spice blends. The flexible bottling line supports both glass jars and PET bottles, combining precise dosing with automatic capping and marking. Compact and efficient, it is an ideal spice bottle filling solution for manufacturers aiming to increase productivity while maintaining strict quality control.

Package Type:

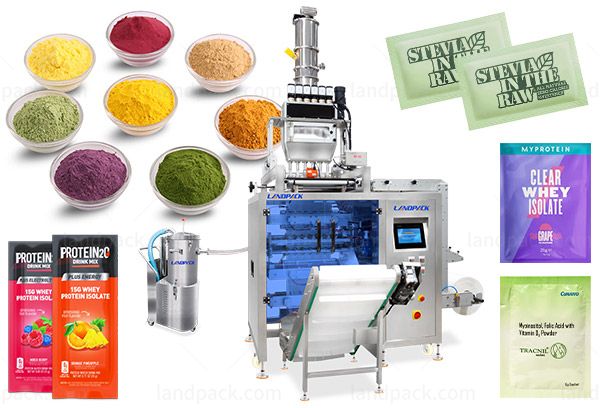

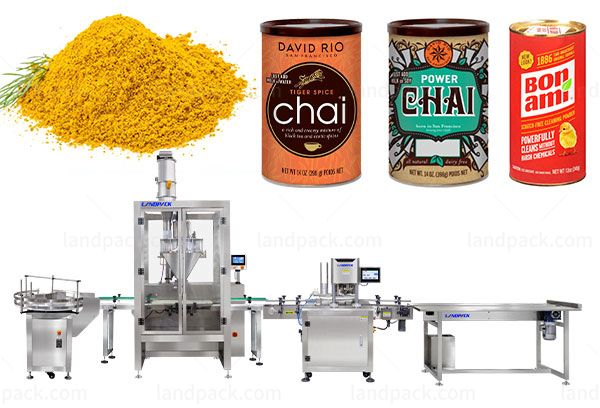

This adaptable bottling line is designed to handle a wide range of rigid container types with minimal changeover time. Whether using classic glass jars or lightweight plastic containers, the spice filling system ensures smooth product flow and accurate positioning across plastic bottles and jars, glass containers, metal tins, and cans in various shapes and formats.

Suitable Products:

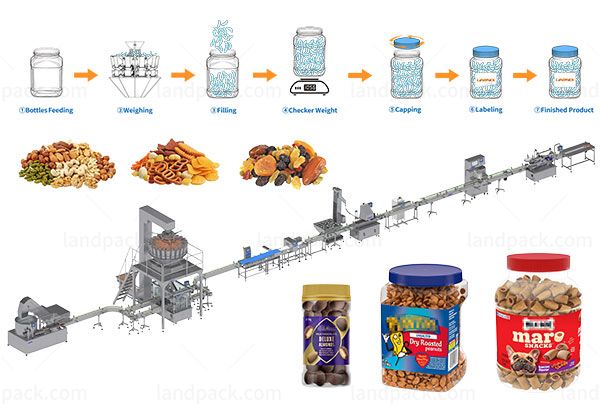

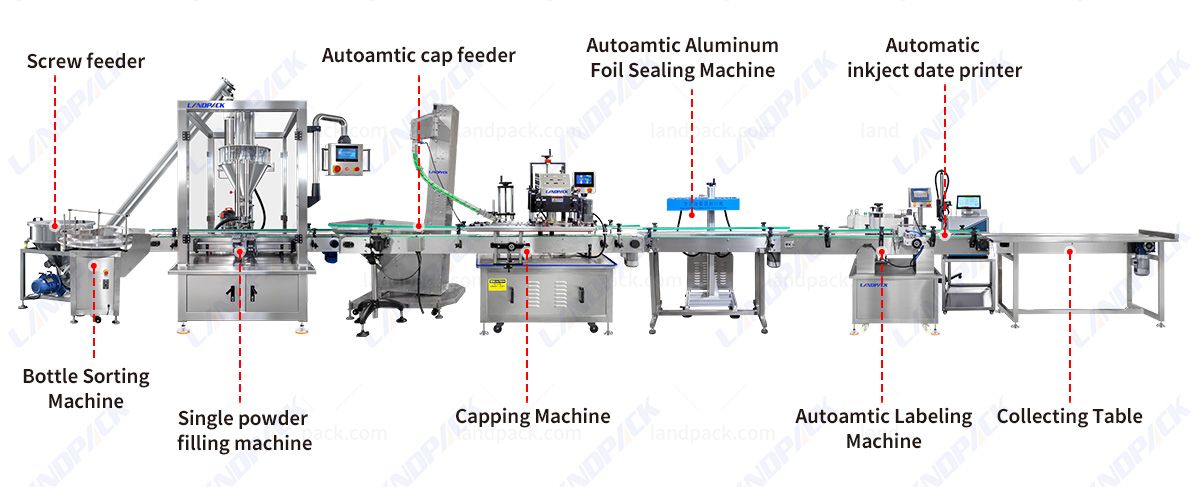

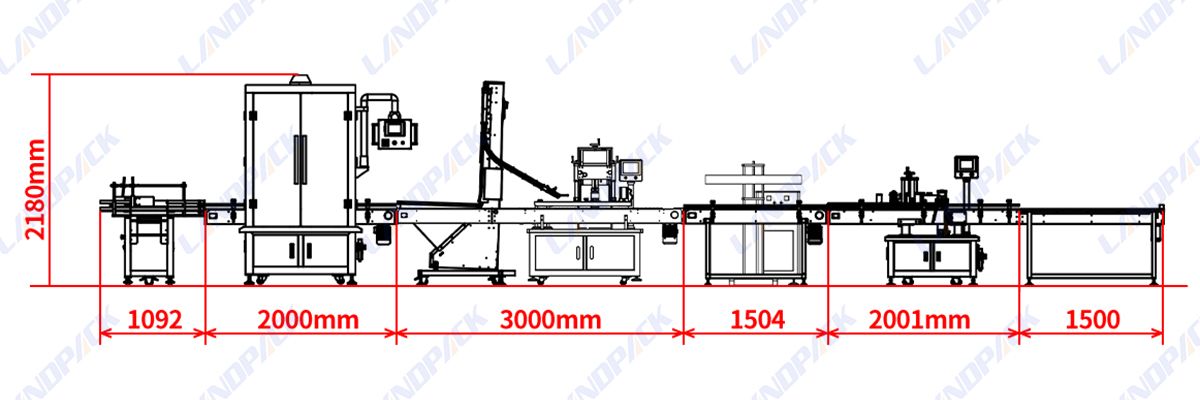

This fully automatic chili powder and spice filling line combines bottle unscrambling, single-head powder filling, cap lifting and capping, aluminum foil sealing, labeling, and finished product collection into a compact and efficient system.

Designed for spice and seasoning powders, all product-contact parts are made of SS304 stainless steel to ensure hygiene and food safety. With a stable output of 15–20 bottles per minute, it is ideal for professional spice manufacturers.

1. Chili & Pure Spice Powders: chili powder, paprika powder, garlic powder, ginger powder, turmeric powder, cumin powder

2. Seasoning & Flavor Blend Powders: flavoring powder, chicken flavor powder, beef flavor powder, soup base powder

3. Salt & Salt-based Powders: fine sea salt powder, iodized salt powder, seasoned salt powder

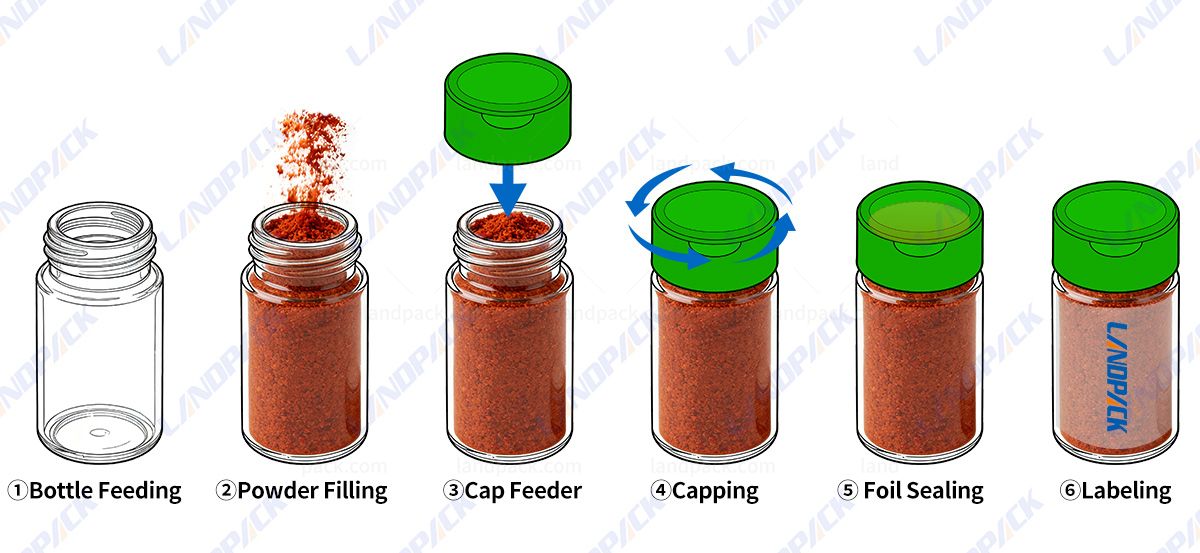

Workflow:

1. Bottle Feeding: Automatic loading via turntable or conveyor for a continuous container flow.

2. Powder Filling: High-precision auger dosing specifically calibrated for fine and granulated spices.

3. Cap Feeding: Synchronized sorting and delivery of caps to the capping head.

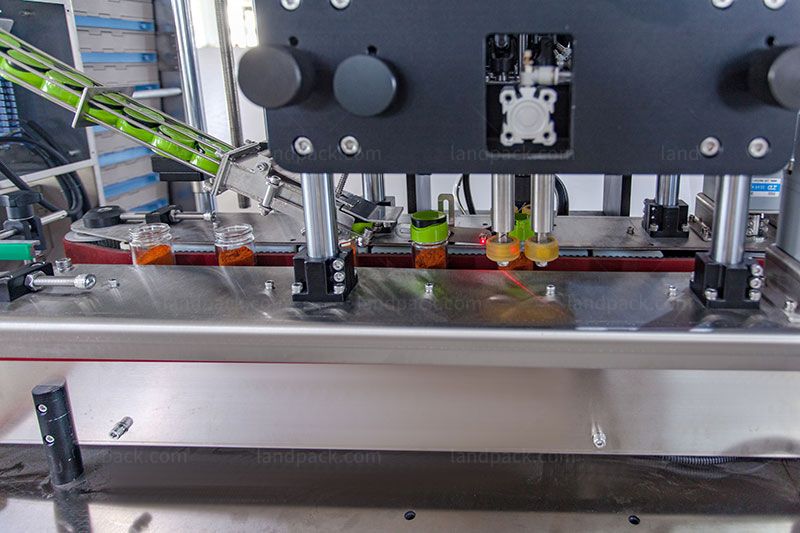

4. Capping: A solid screw cap that can be adjusted to prevent leaks or overtightening.

5. Foil Sealing: High-frequency induction sealing that preserves the flavor of spices and offers tamper-evident evidence.

6. Labeling: Precise wrap-around or side-surface application for a professional retail finish.

| Single Head Powder Automatic Filling Machine | ||

| Item | LFP-01(Single Head) | LFP-01(Dual Head) |

| Model | LFP-01 | LFP-01 |

| Filling Weight | 10-5000 g(by changing auger) | 10-5000 g(by changing auger) |

| Bottle Diameter | Φ30-Φ140 mm (customizable) | Φ30-Φ140 mm (customizable) |

| Bottle Height | 50-200mm (customizable) | 50-200 mm (customizable) |

| Capacity | 10-20 bottles/min | 20-40 bottles/min |

| Filling Accuracy | 500g:1% >500g:0.5%(varies bymaterial) | |

| Power Consumption | 2.5kW | 5kW |

| Hopper Capacity | 50L | 50L |

| Power Supply | 220V,50Hz | 220V,50Hz |

| Air Pressure | 0.6-0.8 MPa | 0.6-0.8 MPa |

| Machine Weight | 350kg | 550 kg |

| High Speed Capping Machine | ||

| Model | LFX-GS-150(Eight wheel capping) | LFX-GS-250(Six wheel capping) |

| Capacity | 40-100 Bottles/min | 30-80 Bottles/min |

| Bottle cap diameter | Φ18mm-Φ80mm(Could be customized) | Φ18mm-Φ80mm(Could be customized) |

| Bottle diameter | Φ35mm-Φ140mm(Could be customized) | Φ35mm-Φ140mm(Could be customized) |

| Bottle sealing height | 38mm-300mm(Could be customized) | 38mm-300mm(Could be customized) |

| Power | 2KW | 1.5KW |

| Voltage | 220V, 50HZ | 220V, 50HZ |

| Air pressure | 0.6-0.8Mpa | 0.5-0.7Mpa |

| Weight | 350kg | 300kg |

| Dimensions | H3120*W1544*L2122 | H3100*W1244*L2122 |

| Automatic Aluminum Foil Sealing Machine | ||

| Model | LD-ZS (Double Heads Aluminum Foil Sealing) | LF-LB-2000 (Single Heads Aluminum Foil Sealing) |

| Applicable bottle diameter | Φ10-Φ200mm (Could be customized) | Φ10-Φ200mm (Could be customized) |

| Applicable bottle height | H: 40-300mm (Could be customized) | H: 40-300mm (Could be customized) |

| Speed | 0-30 bottles/min | 0-10 bottles/min |

| Bottle material | Glass, ceramics, plastics, metals | Glass, ceramics, plastics, metals |

| Voltage | 220V, 50HZ | 220V, 50HZ |

| Power | 1500W | 1200W |

| Dimension | 1500*800*1750mm | 1200*600*1550mm |

| Automatic Labeling Machine | ||

| Model | LFT-YP-00 | |

| Labeling Speed | 20-60 bottles/minute | |

| Labeling Accuracy | ±1mm | |

| Max Label Width | 100mm | |

| Applicable Product Size | Φ30mm-Φ80mm (Can be customized) | |

| Applicableinner diameter of paper | Φ76mm | |

| Applicable outer diameter of paper | Max.Φ330mm | |

| Air Source | 4-6 KG 30L/min | |

| Dimension | 2000*800*1600mm | |

| Voltage | 220V, 50 Hz, 2000W | |

| Weight | 250KG | |

| Inkjet Printer Machine | ||

| Power supply | 220V 60Hz | |

| Printing speed | 1024 seconds (5*7) | |

| Printing materials | Paper, plastic products, pipes, food bags, metal, glass, paper cups, etc. | |

| Store information | The system can store 1000 print information | |

| Machine size | length 370mm width 260mm height 500mm | |

| Ink consumption | 70 million words per print (5*7) | |

| Machine weight | 21kg | |

| Package size | 560*350*570mm | |

Machine Key Components:

1. Bottle Feeder

2. Bottle Filling Machine

3. Cap Feeder

4. Capping Machine

5. Foil Sealing Machine

6. Labeling Machine

Feature:

Bottle Feeder A high-speed rotary turntable continuously feeds empty jars onto the conveyor, minimizing manual handling and preventing congestion at the infeed section. |  |

| Bottle Filling Machine The system uses a servo-controlled auger optimized for spice applications, delivering accurate weights for fine powders and granules while keeping dust to a minimum. |

Cap Feeder Caps are automatically sorted and supplied in the correct orientation, with a sensor-controlled elevator or vibratory feeder that stops when the cap chute is full. |  |

| Capping Machine Adjustable capping torque protects caps from damage while ensuring tight, leak-resistant closures across a range of screw-cap types. |

Foil Sealing Machine High-frequency electromagnetic sealing produces a tamper-proof, airtight liner seal, helping preserve spice freshness and extend product shelf life. |  |

| Labeling Machine A precision labeling system with advanced sensors applies wrap-around or side labels accurately, delivering a smooth, wrinkle-free appearance suitable for retail display. |

Get Price & More Detail