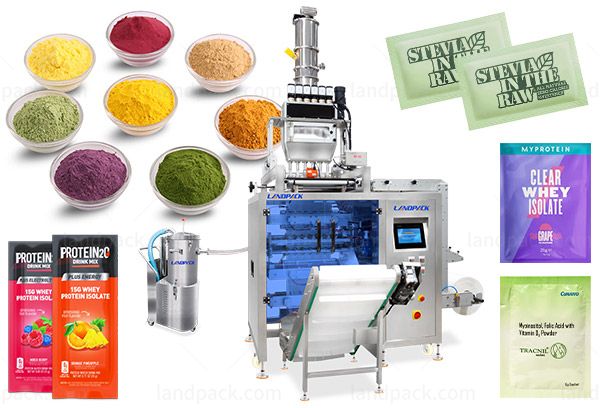

Automatic Seasoning Spice Bottle Filling Capping And Labeling Machine

Model: Spice Bottle Filling Capping And Labeling Machine

Application:

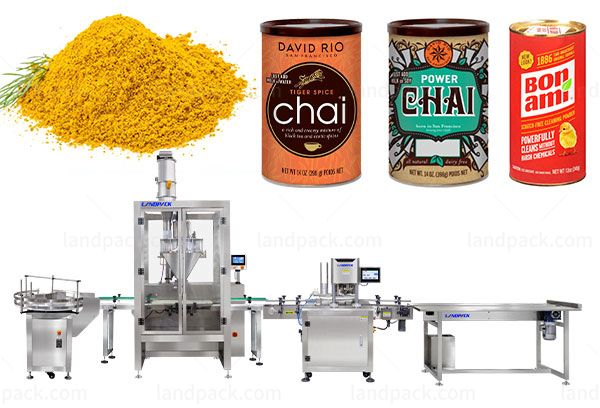

This fully automatic condiment bottle filling machine integrates filling, capping, and labeling, with a maximum speed of 50 bottles per minute. It is also suitable for various fine particles such as salt, sugar, pepper, coffee granules, and candy.

Application:

This spice bottle filling machine is designed for fully automated filling, capping, and labeling of seasoning and spice products. It operates at speeds up to 50 bottles per minute and is widely used for filling spices, seasonings, chili peppers, black pepper, sugar, salt, cumin seeds, and mixed seasonings.

Package Type:

This spice bottle filling machine is compatible with various bottle and cap styles for granular seasoning products, ensuring flexible and precise packaging. Such as Glass Bottles, PET Bottles, Plastic Bottles, Aluminum Bottles

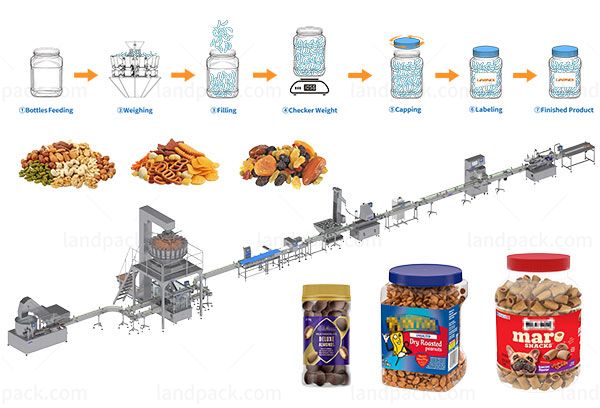

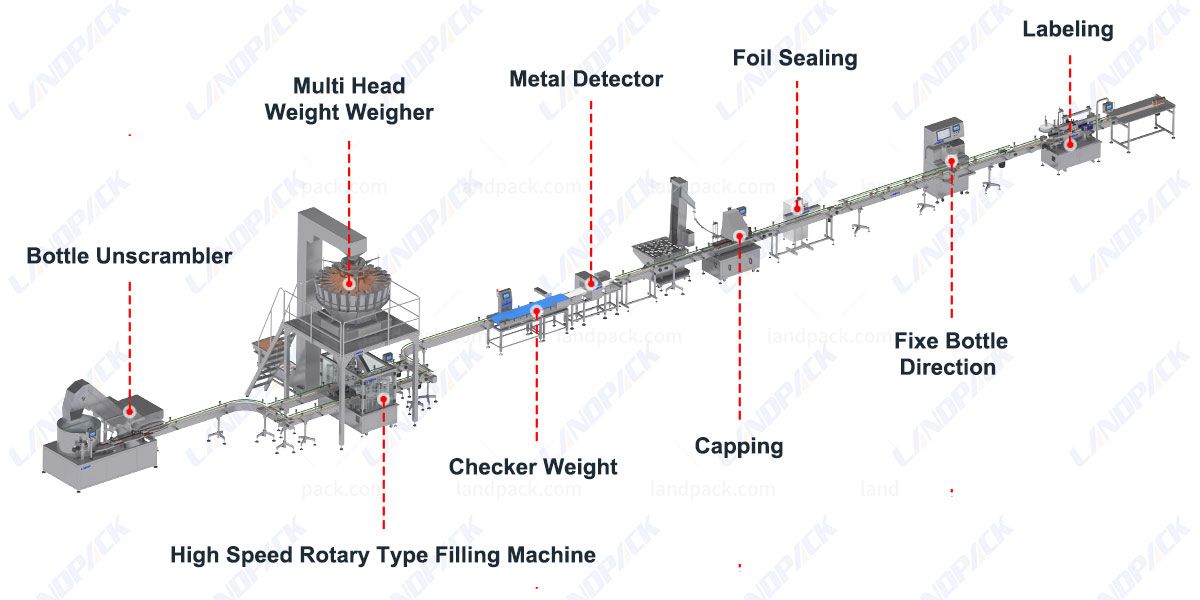

Workflow:

1.Bottles Feeding → 2. Material Weighing → 3. Rotary Filling → 4. Weight Checking → 5. Metal Detecting → 6. Capping → 7. Foil Sealing → 8. Vision Inspection → 9. 3-Side Labeling → 10. Output and Collecting

| High-speed Bottle Unscrambler | |||||

| Model | LFL-800 | ||||

| Capacity | 10rpm | ||||

| Bottle diameter | Φ30-100mm (Could be customized) | ||||

| Bottle height | 30-120mm (Could be customized) | ||||

| Power | 200W | ||||

| Voltage | 220V, 50HZ | ||||

| Weight | 50kg | ||||

| Multi-heads granules weighing double heads rotary filling machine | |||||

| Model | LD-GZJ200M-R(double turntable filling) | LD-GZJ100M-R(Single turntable filling) | |||

| Material | 304# Stainless steel | 304# Stainless steel | |||

| Filling diameter | Φ40-130mm | Φ40-130mm | |||

| Applicable height | 50-200mm | 50-200mm | |||

| Filling speed | 30-50 cans/min | 10-20 cans/min | |||

| Air source | 0.6-0.8Mpa | 0.3-0.5Mpa | |||

| Voltage | 220V, 50HZ | 220V, 50HZ | |||

| Power | 2.5KW | 1.5KW | |||

| N.W./G.W. | 200/320KGS | 100/220KGS | |||

| Size | 2000*1000*1400mm | 2000*500*1400 | |||

| Automatic Weight Detector | |||||

| Model | LD10 | LD100 | LD201 | LD401 | LD1000 |

| Weight Range | 10-99g | 100-200g | 201-400g | 401-999g | 1000-10000g |

| Rate | 65 bags/min | 60 bags/min | 50 bags/min | 45 bags/min | 40 bags/min |

| Precision | ±0.5g | ±1g | |||

| Minimum scale | 0.1g | ||||

| Predesign pattern | 10kinds | ||||

| Size | 1050*681*1260mm | ||||

| Voltage | 220V | ||||

| Power | 300W | ||||

| Metal Detector | |||||

| Model | LD-100 | LD-150 | |||

| Detecting window height(mm) | 100 | 150 | |||

| Effective Detecting width(Max)(mm) | 400 | 400 | |||

| Fe(mm)-iron ball-steel ball(mm) | 0.8-1.0 | 1.0-1.2 | |||

| 304Sus(mm)304-306(mm) | 1.5-2.0 | 2.0-2.3 | |||

| Frame material | Stainless Steel | Stainless Steel | |||

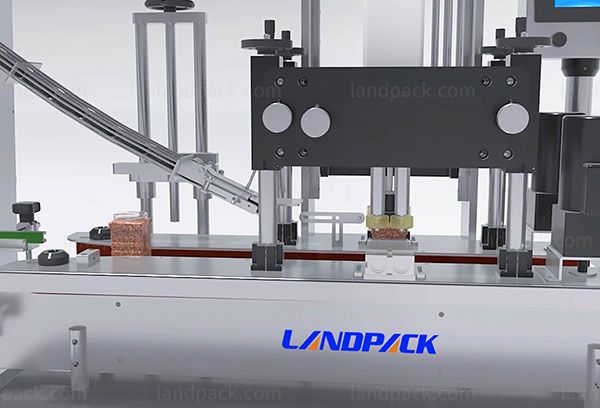

| Automatic capping machine | |||||

| Model | LFX-JX-01 (Four wheel capping) | LFX-GS-150(Eight wheel capping) | LFX-GS-250 (Six wheel capping) | ||

| Capacity | 20-50Bottles/min | 40-100Bottles/min | 30-80Bottles/min | ||

| Bottle cap diameter | Φ22mm-80mm | Φ18mm-80mm | Φ18mm-80mm | ||

| Bottle diameter | Φ35mm-140mm | ||||

| Bottle sealing height | 38mm-300mm | ||||

| Power | 1.5KW | 2KW | 1.5KW | ||

| Voltage | 220V, 50HZ | ||||

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.5-0.7Mpa | ||

| Weight | 250kg | 350kg | 300kg | ||

| Dimensions | H3000*W800*L1600mm | H3120*W1544*L2122 | H3100*W1244*L2122 | ||

Aluminum foil sealing machine | |||||

| Model | LD-ZS (Double Heads Aluminum Foil Sealing) | LF-LB-2000 (Single Heads Aluminum Foil Sealing) | |||

Applicable bottle diameter | Φ10-200mm (Could be customized) | ||||

Applicable bottle height | H:40-300mm (Could be customized) | ||||

Speed | 0-30bottles/min | 0-10bottles/min | |||

Bottle material | Glass, ceramics, plastics, metals | ||||

Voltage | 220V, 50HZ | ||||

Power | 1500W | 1200W | |||

Dimension | 1500*800*1750mm | 1200*600*1550mm | |||

| Vision Inspection and Orientation Machine | |||||

| Model | LDRU-04 | ||||

| Dimensions | Length 1 meter, Width 0.8 meters, Height 1.8 meters | ||||

| Production Speed | 3000BPH | ||||

| Air Supply Pressure | 0.3Mpa | ||||

| Air Consumption | 0.1m³/h | ||||

| Suitable Bottle Types | Depend on customer bottles | ||||

| Power | 1.5KW,220V,50Hz | ||||

| Weight | 300KG | ||||

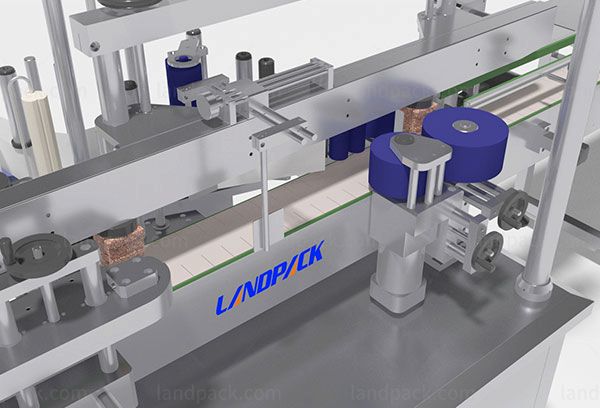

| Automatic Labeling Machine | |||||

| Model | LFT-SM-200C(double heads labeling) | LFT-SM-100C(Single heads labeling) | |||

| Labeling speed | 10-40 Bottles/min | 5-20 Bottles/min | |||

| Labeling accuracy | ±1mm | ||||

| Label maximum width | 200mm (Could be customized) | 150mm (Could be customized) | |||

| Size of the object being attached | Heights400mm; Thicknesss100mm | ||||

| Label ID | Φ76.2mm | Φ25.4mm | |||

| Label OD | MaxΦ330mm | MaxΦ230mm | |||

| Voltage | 220V, 50HZ | ||||

| Power | 3.5KW | 2.5KW | |||

| Weight | 500kg | 400kg | |||

| Dimension | L3002*W1478*H1810mm | L2950*W1400*H1810mm | |||

Machine Key Components:

Feature:

1. Automatic fragrance bottle filling machine, integrating filling, capping, sealing, and labeling.

2. High-precision rotary filling machine.

3. Equipped with weight and metal detection functions.

4. Automatic bottle feeding and orientation adjustment improve filling, capping, and labeling efficiency.

5. Aluminum foil sealing ensures hygiene and product freshness.

6. Three-sided labeling system, high speed and precision.

7. Compatible with various cap types of glass, PET, and plastic bottles.

8. Vision inspection ensures accurate bottle positioning and guarantees filling accuracy.

9. Stable and high-speed operation, up to 50 bottles/minute.

10. Simple operation and maintenance, reducing labor costs and improving efficiency.

Get Price & More Detail