Juice Jelly Horizontal Pouch Packing Machine Spout Pouch Filling and Sealing Machine

Model: LDSP-260L

This type of machine is widely used for packaging a variety of liquid and semi-liquid products in industries such as food and beverage, cosmetics, pharmaceuticals, and household goods.

Application:

It is ideal for packaging a wide variety of liquid and semi-liquid products, including juice, milk, laundry detergent, baby puree, juice, sauces, jelly, butter, pastes, and chemical liquids, ensuring efficiency and precision in every step of the process.

What is a Juice Horizontal Pouch Packing Machine?

A horizontal pouch packing machine for spout pouches is an automated system designed for the efficient filling and sealing of pre-made, flexible pouches that have an integrated spout. These machines are a key component in a variety of industries, including food and beverage, cosmetics, and household goods, for packaging liquid and semi-liquid products.

Application:

It is ideal for packaging a wide variety of liquid and semi-liquid products, including juice, milk, laundry detergent, baby puree, juice, sauces, jelly, butter, ketchup, lotion, syrup, pastes, and chemical liquids, ensuring efficiency and precision in every step of the process.

Package Type:

This automatic horizontal pouch packing machine is compatible with spout pouches, stand-up pouches, and flat pouches, providing flexible packaging options for various liquid and semi-liquid products.

Workflow:

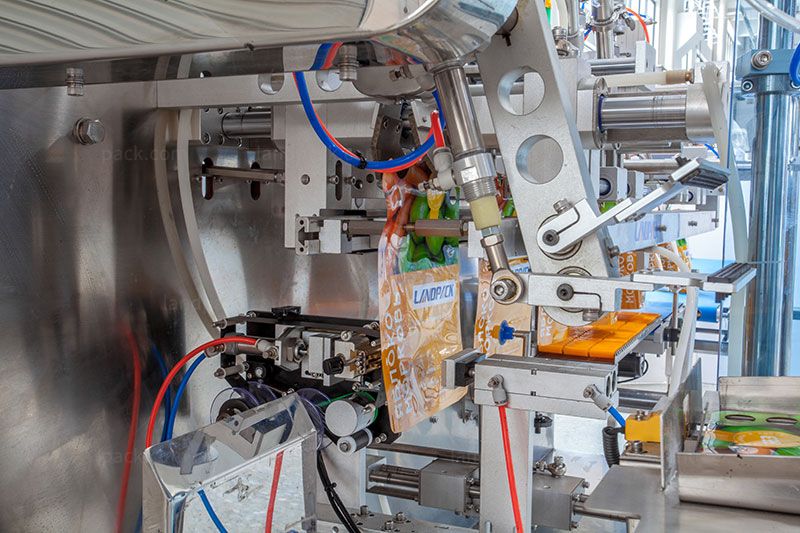

This is automatic horizontal pouch filling and sealing machine for liquid/paste products in spout pouches. Here's how it works step-by-step:

1. Mixer Feeding Tank

2. Automatic Empty Pouch Feeding Device

3. Bag Opening Device

4. 2 Nozzles Filling Machine

5. Automatic Nitrogen Filling Device

6. Double Sealing Station

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | spout pouches, 3-side, 4 side sealing bag, stand-up bag, handbag, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | |||

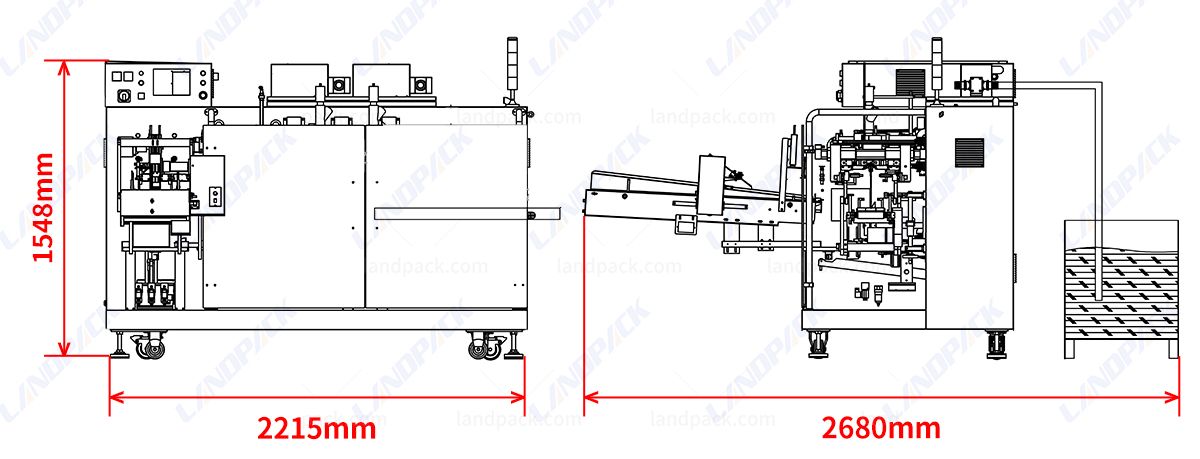

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | |

| Collocation | Screw metering, screw elevator | |||

Machine Key Components:

* Central Storage Hopper: The main reservoir that stores the bulk material prior to its precise portioning and discharge.

* Control Panel: The main interface panel providing operators with complete command over all machine operations, settings, and monitoring.

* Bag Gripping & Manipulation Unit: A mechanism that uses air-powered clamps to securely grasp and position the open bag directly beneath the fill nozzles.

* Weighing Scale: The integrated high-accuracy scale (housed beneath the hopper) responsible for measuring the exact product weight.

* Ribbon Code Printer: A built-in printer that marks each filled bag with vital data, including batch codes, best-before dates, or barcodes.

* Dual Nozzles: A dual-head dispensing system that releases the measured product into two bags at once, significantly boosting output speed.

* Dual-Sealing Mechanism: An integrated system that creates two parallel seals on each filled bag, ensuring a secure closure for enhanced product protection and leak prevention.

* Discharge Conveyor: A belt system that receives the finished, sealed, and labeled bags, moving them smoothly downstream for boxing or palletizing.

Feature:

High-Speed Performance Engineered for efficiency and stability, it achieves speeds of up to 50 bags per minute for maximum productivity. |  |

| Heating & Mixing System An integrated heating and mixing function ensures your product remains consistent and high-quality throughout the filling process. |

PLC Control The user-friendly touch screen simplifies machine operation, from initial setup to real-time monitoring. |  |

| Integrated Coding The system includes a ribbon code printer for crisp, clear marking of essential batch, date, or barcode information on every bag. |

Dual Nozzle Design With its two-nozzle design, the machine fills bags simultaneously, making the process much faster and more efficient. |  |

| Seamless Conveyance The system includes an output conveyor that automatically transfers completed bags, creating a continuous and efficient workflow. |

Get Price & More Detail