Automatic Horizontal Cartoning Machine 20-60 Cartons/min

Model: Cartoning Machine

This system is extensively employed for the automated boxing of beauty and personal care items, including creams, lotions, facial washes, fragrances, and skincare kits.

Application:

It efficiently handles oral care products, bar soaps, moist towelettes, moisturizers, emulsions, face washes, fragrances, aromatherapy candles, and treatment kits, etc.

Application:

It efficiently handles oral care products, bar soaps, moist towelettes, moisturizers, emulsions, face washes, fragrances, aromatherapy candles, and treatment kits, etc.

Package Type:

Engineered for high-efficiency case and box packaging, this horizontal system supports end, side, and top-loading formats with either tuck-in or adhesive sealing. It offers full compatibility with paperboard cartons across a broad range of dimensions and material thicknesses.

Suitable Products:

The cartoning machine is designed for secondary packaging, integrating automatic carton forming, product feeding, insertion, and box closing in one continuous process. Typical applications include:

- Beauty and Personal Care: Serums, moisturizing creams, hand cream, toothpaste, , and high-end fragrance.

- Daily Essentials: Toothpaste, soap, disinfectant wet wipes, and laundry pods.

- Medical and Health: Treatment kits, ointment tubes, medical disposables, and adhesive bandages.

Workflow:

1. Product Feeding: Products are automatically transported and organized for a steady, continuous supply.

2. Leaflet Insertion: Instructional manuals are precisely inserted into each case as specified.

3. Carton Erecting: Flat cartons are retrieved, expanded, and aligned by the mechanical assembly.

5. Product Loading: Items are transitioned smoothly into the pre-formed cartons.

6. Carton Closing: Flaps are folded and secured to create a clean, professional finish.

7. Finished Carton Output: Finished packages are discharged for final casing or robotic palletizing.

| Model | LD-80A | LD-80L | |

| Cartoning speed | 30-70 Cartons/min | 20-60 Cartons/min | |

| Carton | Quality requirement | 250-450g/m2(According to box dimensions) | |

| Dimension range (LxWxH) | L:90-250mm W:50-200mm H:20-80mm | L:120-360mm W:50-260mm H:20-90mm | |

| Compressed air | Working pressure | ≥0.6Mpa | |

| Air consumption | 20m' | ||

| Power supply | 220V/50HZ | ||

| Motor Power | 8kw | ||

| Machine dimension(Lx Wx H) | 5970mm x 1610mm x 2262mm | 6236mm x 1867mm x 2262mm | |

| Machine weight | 1800kg | 2000kg | |

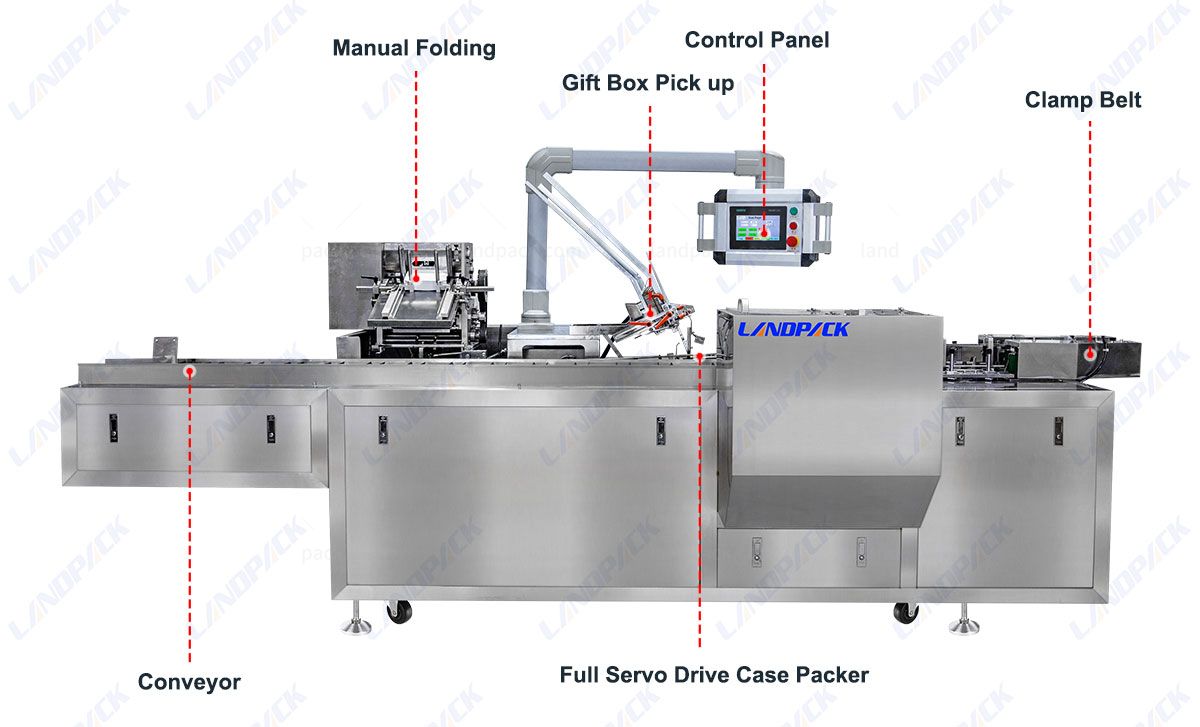

Machine Key Components:

1. Manual Folding

2. Control Panel

3. Gifz Box Pick up

4. Clamp Belt

5. Conveyor

6. Full Servo Drive Case Packer

Feature:

1. Fully automated horizontal cartoning that incorporates cart erecting, product loading leaflet insertion, as well as sealing all in one seamless process.

2. PLC and HMI control system that includes recipe storage, quick changeovers, and real-time parameters adjustment.

3. Product compatibility is high, suited for bottles, tubes and blisters. It is also suitable for sachets, blisters and many other items that are regular in shape.

4. Automatic rejection and detection of the missing product or leaflet to ensure accuracy of packing.

5. Secure and reliable operation, with safety features such as overload alarms, fault alerts and stop-by-automatic functions.

6. Simple operation and maintenance thanks to modular design and clear interface. This reduces the amount of work required.

Get Price & More Detail