Horizontal Cartoner Cartoning Packaging Machine for Pouch, Sachet,Tube,Bottle

Model: Horizontal Cartoning Machine

The horizontal cartoner machine is a fully automatic end load cartoner designed for continuous product feeding, carton erecting, product inserting, and carton sealing. It integrates precise servo control and stable mechanical transmission to consistent cartoning quality for a wide range of packaged products.

Application:

The horizontal cartoning machine is widely used for packing toothpaste, facial cleanser, hand cream, ointment tubes, cosmetic masks, shampoo bottles, soap bars, wet wipes, pharmaceutical blister packs, sachets, medical devices, daily-use stationery, and small hardware accessories.

Application:

The horizontal cartoning machine is widely used for packing toothpaste, facial cleanser, hand cream, ointment tubes, cosmetic masks, shampoo bottles, soap bars, wet wipes, pharmaceutical blister packs, sachets, medical devices, daily-use stationery, and small hardware accessories.

Package Type:

- Compatible with cartons, cases, and paper boxes, including tuck-in boxes and glue-sealed cartons.

- Supports single-piece loading, multi-piece grouping, and insert-with-leaflet packing.

- Suitable for various box sizes with fast adjustment and reliable carton forming.

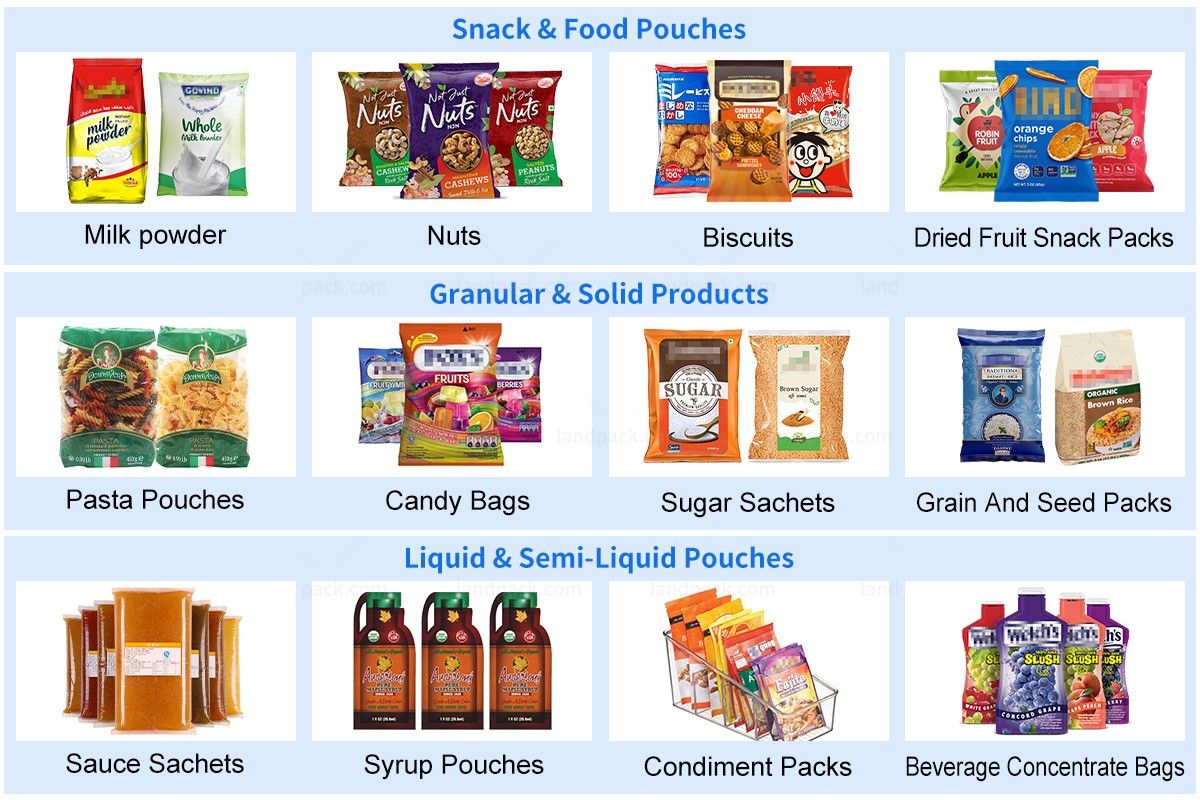

Suitable Products:

Designed for automatic cartoning of regular and semi-regular products, such as:

Food Industry: Biscuits, chocolate bars, wafers, snack packs, instant food sachets

Daily Necessities: Toothpaste, soap bars, wet wipes, detergent packs, household items

Pharmaceutical & Healthcare: blister packs, medicine bottles, ointment tubes, medical disposables

Workflow:

1. Product Feeding – Products are conveyed and spaced evenly to ensure accurate and stable cartoning.

2. Carton Erecting – Flat cartons are automatically picked up, opened, and positioned for loading.

3. Product Insertion – Products are horizontally pushed into the opened cartons with precise positioning.

4. Carton Closing – Cartons are closed by tuck-in or glue sealing

5. Finished Carton Output – Completed cartons are discharged smoothly for packing or palletizing.

| Model | LD-80A | LD-80L | |

| Cartoning speed | 30-70 Cartons/min | 20-60 Cartons/min | |

| Carton | Quality requirement | 250-450g/m2(According to box dimensions) | |

| Dimension range (LxWxH) | L:90-250mm W:50-200mm H:20-80mm | L:120-360mm W:50-260mm H:20-90mm | |

| Compressed air | Working pressure | ≥0.6Mpa | |

| Air consumption | 20m' | ||

| Power supply | 220V/50HZ | ||

| Motor Power | 8kw | ||

| Machine dimension(Lx Wx H) | 5970mm x 1610mm x 2262mm | 6236mm x 1867mm x 2262mm | |

| Machine weight | 1800kg | 2000kg | |

Machine Key Components:

1. Gift Box Pick up

2. Clamp Belt

3. Conveyor

4. Full Servo Drive Case Packer

Feature:

Stable horizontal end-load Design Continuous motion design ensures smooth product transfer as well as efficient cartoning.

Servo and PLC Control System Accurate positioning of the device, storage for recipes and rapid changeover of formats with simple HMI operation.

Large Product Compatibility Uses flow wrapped bags, bottles or stacked items with a high degree of flexibility.

Secure Carton Formation A precise opening and closing to ensure a clean appearance and safe packaging.

Automatic Detection and Protection The missing product detection over-protection, alarm for fault and stop-and-go functions that automatically.

Simple and Easy maintenance: Space-saving layout with modular design that makes it easy to clean and maintenance.

Get Price & More Detail