Automatic Horizontal Side Load Cartoner 20-60 Cartons/Min

Model: LD-60

Designed for Secondary Packaging automation, this machine excels in loading bagged or sachet-packed goods into pre-glued cartons.

Application:

This high-speed secondary packaging system operates at a capacity of 20 to 60 cartons per minute, catering specifically to the food, medical, beauty, household chemical, and retail sectors.

Application:

The equipment automates the entire process—including case forming, product collation, horizontal side-loading, and final carton sealing—for various formats like sachets, sticks, bags, containers, and overwrapped goods.

Package Type:

This machine is engineered for pre-glued paper cartons, accommodating a wide range of styles including tuck-in flap cartons, straight-tuck, and reverse-tuck boxes. It is particularly optimized for gift boxes and premium secondary packaging, ensuring clean edges and precise flap alignment.

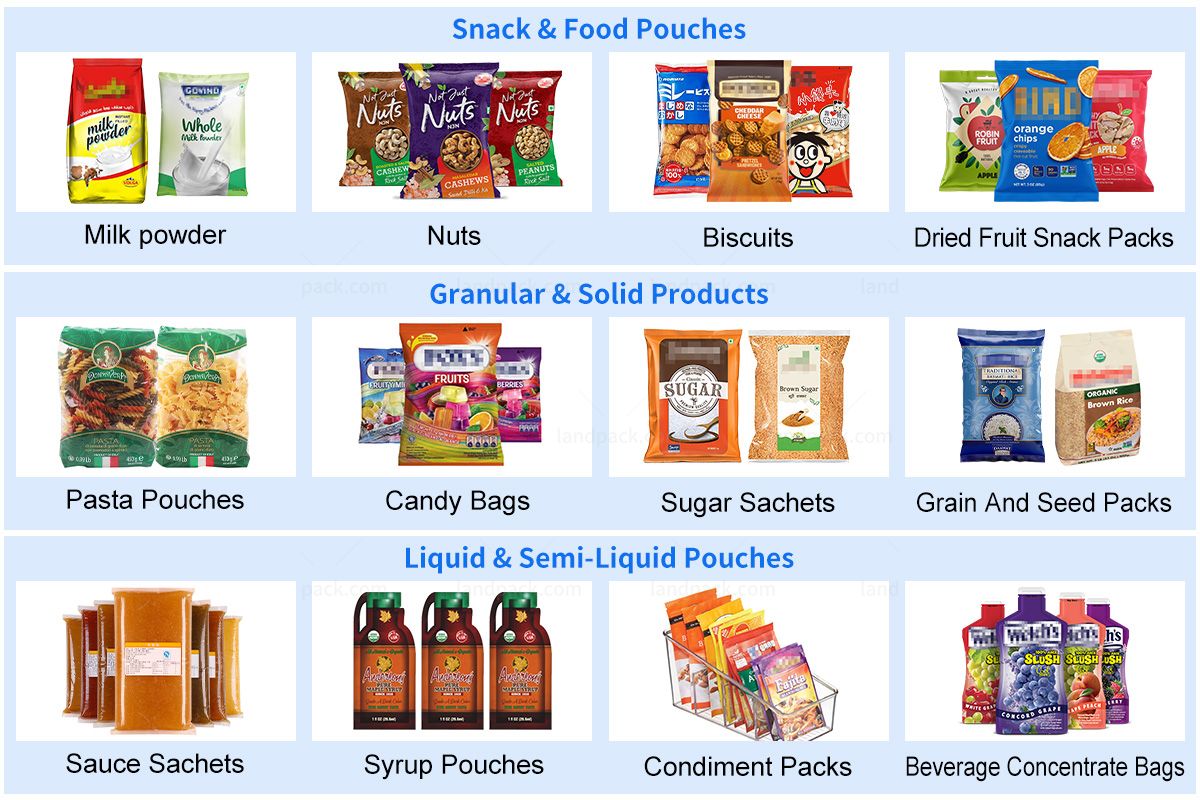

Suitable Products:

Food & Beverage: Juice, ketchup, coffee stick packs, instant noodle seasoning sachets, and snack bags.

Pharmaceutical & Health: Capsule, medical patches, blister cards, and syrup bottles.

Personal Care: Facial mask sheets, toothpaste, cosmetics, travel-size tubes, soap bars, and wet wipe packs.

Workflow:

1. Suction-Feed Cartoning - The rotary vacuum arm extracts carton blanks from the magazine, snapping them into a rigid 90° structure.

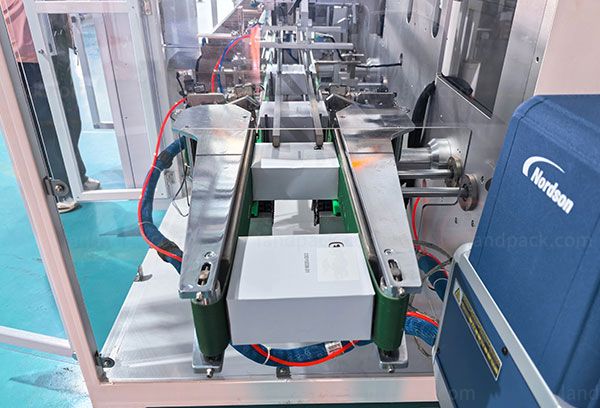

2. Servo-Timed Infeed - Products are synchronized via the Clamp Belt and transferred to the loading station without jamming.

3. Lateral Insertion - A servo-driven pusher executes horizontal end-loading, ensuring zero-damage to fragile bag contents.

4. Integrated Sealing - Depending on the configuration, flaps are either tucked or precision-dotted with hot-melt adhesive.

5. Quality Outfeed - The Conveyor discharges the finished boxes for check-weighing or case packing.

| Model | LD-60 | LD-60L |

| Cartoning speed | 30-60 Cartons/min | 20-45 Cartons/min |

| Quality requirement | 250-450g/m² (According to box dimensions) | |

| Carton Dimension range (L×W×H) | L: 70-250mm W: 50-180mm H: 20-90mm | L: 120-360mm W: 50-260mm H: 20-90mm |

| Customization | Special size can be customized | |

| Working pressure | ≥ 0.6Mpa | |

| Air consumption | 20m³ | |

| Power supply | 220V / 50Hz | |

| Motor power | 4.5kW | 2kW |

| Machine dimension (L×W×H) | 4528mm x 1630mm x 1950mm | 5630mm x 1821mm x 1950mm |

| Machine weight | 1000kg | 1200kg |

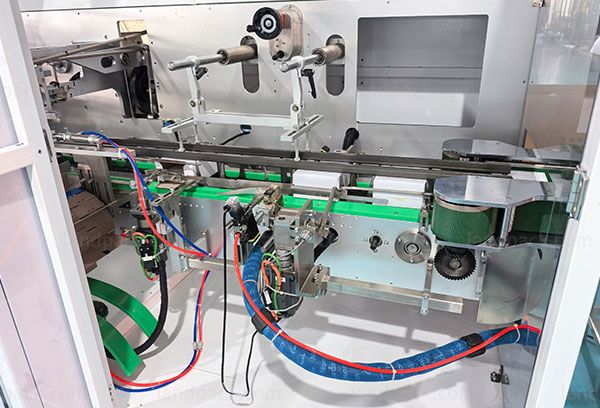

Machine Key Components:

1. Conveyor

2. Gift Box Pick Up

3. Full Servo Drive Case Packer

4. Clamp Belt

Feature:

Full Servo Intelligence - Replaces traditional chains and gears with independent servo motors, reducing noise and mechanical wear.

No Product - No Carton - An optical sensor detects missing infeed items to prevent empty carton waste.

Open Frame Design - The "Landpack" structural layout allows for easy wash-down and debris clearance underneath the conveyor.

Digital Memory - The HMI stores up to 50 product recipes, allowing for "one-button" size adjustments during product switching.

Get Price & More Detail