Cartoning Machine For Horizontal Pouch Bag Sachet Stick

Model: LD-ZHJ300

The horizontal cartoning machine is designed for efficient secondary packaging at a speed of 30–50 cartons/min.

Application:

This equipment is extensively utilized across sectors such as food processing, medical, beauty, household chemical, and retail manufacturing. It is designed for maximum flexibility, functioning as a standalone unit or seamlessly connecting with bagging and filling hardware to create a comprehensive, autonomous production system.

Application:

This equipment is extensively utilized across sectors such as food processing, medical, beauty, household chemical, and retail manufacturing. It is designed for maximum flexibility, functioning as a standalone unit or seamlessly connecting with bagging and filling hardware to create a comprehensive, autonomous production system.

Package Type:

This cartoning machine handles a variety of pre-glued cartons, including tuck-in flap, straight-tuck, and reverse-tuck styles, making it ideal for both retail-ready and protective secondary packaging needs.

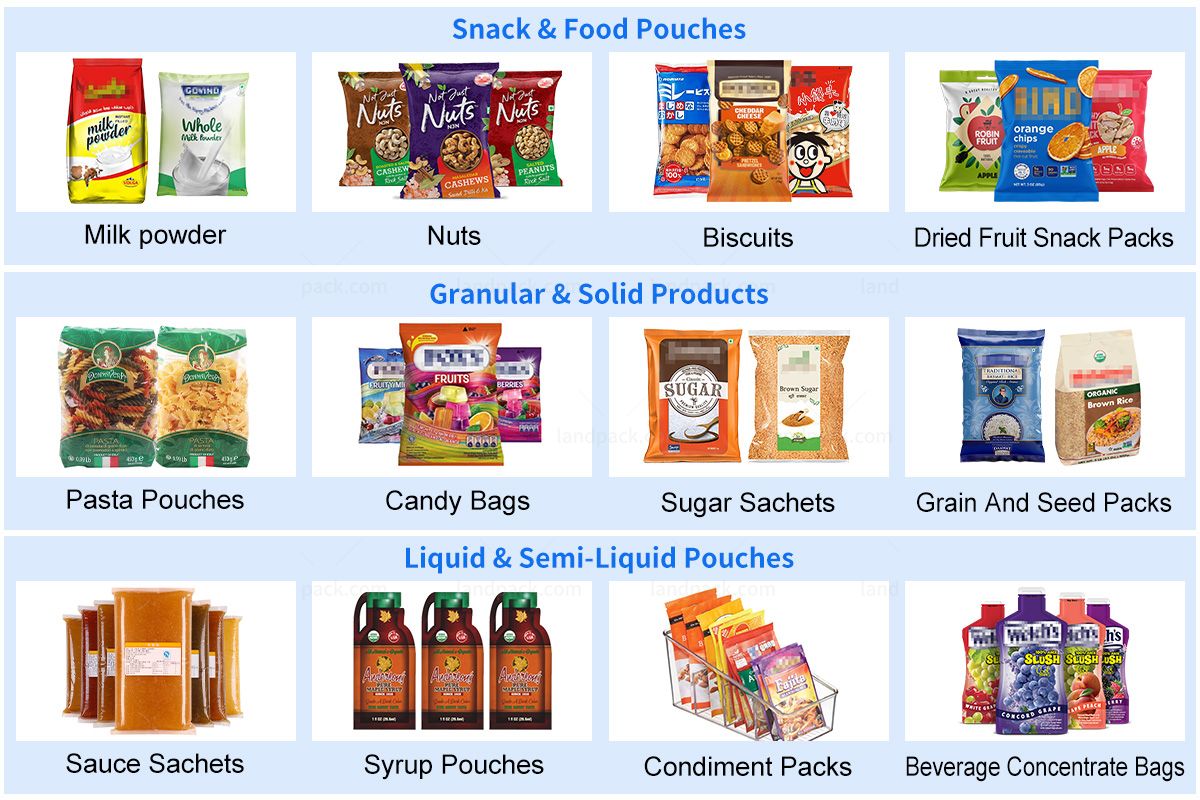

Suitable Products:

The Horizontal Cartoning System is engineered to serve diverse markets, spanning the food, drink, medical, beauty, household chemical, and retail sectors. It provides high-efficiency packing for a broad spectrum of formats—including bags, small packets, stick packs, pouches, and bundled goods—into cartons suited for retail-ready displays or secondary logistics solutions.

Workflow:

1. Product Conveying: Items are moved from the upstream line toward the cartoning station via an integrated supply conveyor.

2. Counting & Sorting: The system automatically tallies and aligns the units to ensure they are correctly grouped for insertion.

3. Carton Box Pick-up & Forming: Flat, pre-glued cases are retrieved from the magazine, opened into shape, and aligned for the loading stage.

4. Product Loading: The organized product batches are smoothly transitioned horizontally into the waiting open cartons.

5. Carton Box Closing: The machine folds and secures the box flaps, finalizing the packaging cycle for a ready-to-ship product.

| Model | LD-ZHJ300 | ||||

| Power supply | 220V, 50Hz, 0.75kW | ||||

| Air pressure requirement | 0.5-0.8MPa | ||||

| Machine material | Aluminum + stainless steel | ||||

| Applicable | L: 120-300mm, W: 30-150mm, H: 20-60mm | ||||

| Size of carton | Customizable | ||||

| Box material | 300-450g cardboard paper, corrugated paper | ||||

| Working speed | 30-50 cartons/min | ||||

| Machine size | 4008*1354*1633 mm | ||||

| Weight | About 1500kg | ||||

Machine Key Components:

1. Conveyor Belt

2. Gift Box Pick Up

3. Servo Drive Case Packer

4. Clamp Belt

Feature:

1. High-Speed & Stable Operation: Delivers 30–50 CPM, providing reliable performance for medium-to-high-speed workflows.

2. Wide Product Compatibility: Processes diverse items, including bags, pouches, sticks, canisters, tubes, and blister sheets.

3. Flexible Carton Adaptability: Compatible with pre-glued straight or reverse-tuck cartons for retail and secondary needs.

4. Fully Automatic Process: Unifies case erecting, product grouping, horizontal loading, and sealing into one smooth cycle.

5. Easy Integration & Scalability: Works independently or interfaces with upstream/downstream units for a fully automated line.

6. User-Friendly Operation & Maintenance: Touch-screen HMI and modular design ensure fast configuration and effortless maintenance.

7. Robust & Hygienic Construction: Stainless steel contact surfaces comply with FDA/GMP standards for food, pharma, and cosmetics.

Get Price & More Detail