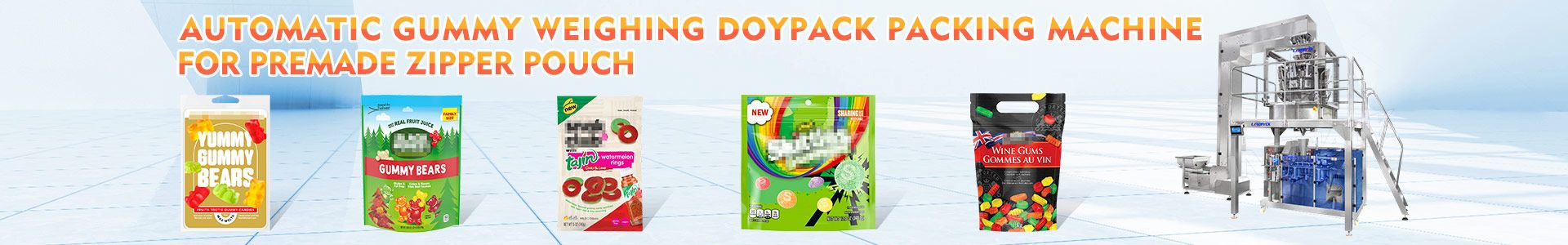

Multi-function Premade Pouch Packing Machine For gummy bear

Model: Gummy Weighing Doypack Packing Machine

The LD-8300A rotary premade pouch packaging machine is specially designed for automatic gummy packing. It integrates bag feeding, opening, accurate dosing, filling, sealing, and output.

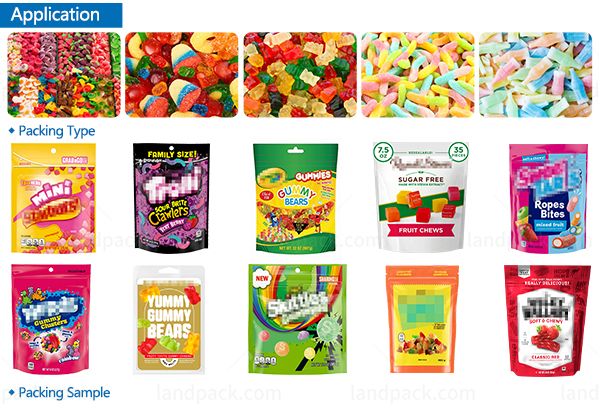

Application:

The LD-8300A is perfectly suited for the packaging of various gummy and confectionery products, offering flexible solutions for different bag types and product characteristics. It is widely used for fruit gummies, vitamin gummies, jelly candies, functional supplements, and chewy sweets, ensuring accurate filling and attractive pouch presentation.

Application:

The LD-8300A is perfectly suited for the packaging of various gummy and confectionery products, offering flexible solutions for different bag types and product characteristics. It is widely used for fruit gummies, vitamin gummies, jelly candies, functional supplements, and chewy sweets, ensuring accurate filling and attractive pouch presentation.

Suitable Products:

The LD-8300A can be used for the packaging of various semi-soft and solid products that require precise dosing and easy handling. It is especially suitable for candies made of gummy, such as vitamin gummies, fruit Gummies, and functional supplement Gummies. In addition to gummies, this machine can also be used for other snack or confectionery products like chocolate beans, chewy sweets and tiny jellies. The machine's solid weighing and sealing capabilities ensures the integrity of the product and its appearance which makes it a flexible solution for nutraceutical and food industries.

Workflow:

1. Bag Feeding: Pre-made pouches are automatically picked and delivered to the rotary indexing system, ensuring smooth and continuous operation.

2. Bag Opening: The machine gently opens the pouch using vacuum suction, preparing it for accurate product filling.

3. Product Weighing: A high-precision multihead weigher measures the exact quantity of gummies, ensuring each pouch contains the correct weight.

4. Product Filling : Measured gummies are dropped cleanly into the opened pouches without damage or sticking, maintaining product quality.

5. Sealing: The filled pouch is sealed through a stable and temperature-controlled heat-sealing system to ensure airtight closure.

6. Date Coding (Optional) : A coding device can print production date, batch number, or expiry information as needed.

7. Finished Product Output: The sealed pouches are discharged neatly for manual collection or conveyed to the next packing stage.

| Model | LD-8300A |

| Name | Automatic Doypack Packing machine |

| Sealing number | 8 |

| Packing Speed | 40 bags/ min |

| Applicable can Height | 30-200mm (Adjustable) |

| Applicable can diameter | 40-150mm (Adjustable) |

| Air sourse | 0.6-0.8MPa |

| Power | 2.5KW |

| Weight | 2500K |

| Size | 10000mm*3900mm*3000mm |

| Voltage | 380V/220V,50Hz |

Machine Key Components:

1. Z Type Elevator

2. Support Platform

3. Control Panel

4. Horizontal bag giving device

5. Multi-heads Weigher

6. Rotary Doypack Machine

7. Output Feeding Conveyor

Feature:

Eight-Station Rotary Structure The system is fully automated and has eight stations design that allows continuous pouch feeding opening, closing, filling and sealing. It ensures smooth operation, steady performance, and a high level of packaging efficiency for gummy items. |  |

| High-Precision Weighing System It is equipped with a multihead weighter to ensure precise dosing, and minimal waste of product. Perfect to handle the soft and irregular shapes of gummy with a consistent level of accuracy. |

Intelligent Control & Easy Operation A PLC-integrated control system that is a touch-screen interface that allows real-time adjustment of parameters as well as display of errors and monitoring of production, providing user-friendly and easy operation. |  |

| Hygienic & Durable Construction |

Flexible Pouch Compatibility The system supports a range of pouches, including stand-up, zipper as well as flat pouch. It allows quick changeovers for various sizes of pouches and sealing formats, increasing productivity flexibility. |  |

| Reliable Sealing Performance Utilizes a precise temperature-controlled sealing system that ensures firm, leak-proof, and aesthetically pleasing pouch seals, maintaining the freshness and integrity of gummies. |

Get Price & More Detail