Gummy Filling Packaging Machine With Multihead Weigher

Application:

This Gummy Packaging Machine equipped with Multihead Weigher is specifically made for precise and fast packaging of a variety of gummy products such as gummy bears, jam candies, fruit gummies and vitamin gummies. This machine for packaging gummies ensures exact weighing, quick filling, and secure seals at up to 60 bags/min, which makes it suitable for confectionery, food, and health supplement companies.

Application:

This Gummy Packaging Machine equipped with Multihead Weigher is specifically made for precise and fast packaging of a variety of gummy products such as gummy bears, jam candies, fruit gummies and vitamin gummies. This machine for packaging gummies ensures exact weighing, quick filling, and secure seals at up to 60 bags/min, which makes it suitable for confectionery, food, and health supplement companies. With modern Gummy packaging equipment that ensures the same weight, reduces material waste and increases productivity and makes it is a top option among reputable manufacturers of gummy packaging machines worldwide.

Package Type:

This high-speed gummy packaging machine is suitable for packing back sealing bags, pillow bags, and gusset bags with or without easy tear.

Suitable Products:

This Gummy Filling Machinery for Packaging with Multihead Weigher is suitable for a wide range of gummy items and other granules:

1. Gummy Candies: Gummies with fruit flavors, vitamins, jelly candy soft chewies, sugar-coated Gummies

2. Caramels and Soft Candies: Toffee, soft candy, milk chewies made of chocolate, caramel cubes

3. Jelly-based and Gel-Based Snacks: mini jelly bites, collagen gummies and healthy functional Gummies

4. Customized and Mixed Products: Gummies that come in various flavors or colors. sweetened with vitamins or sugar-free candies

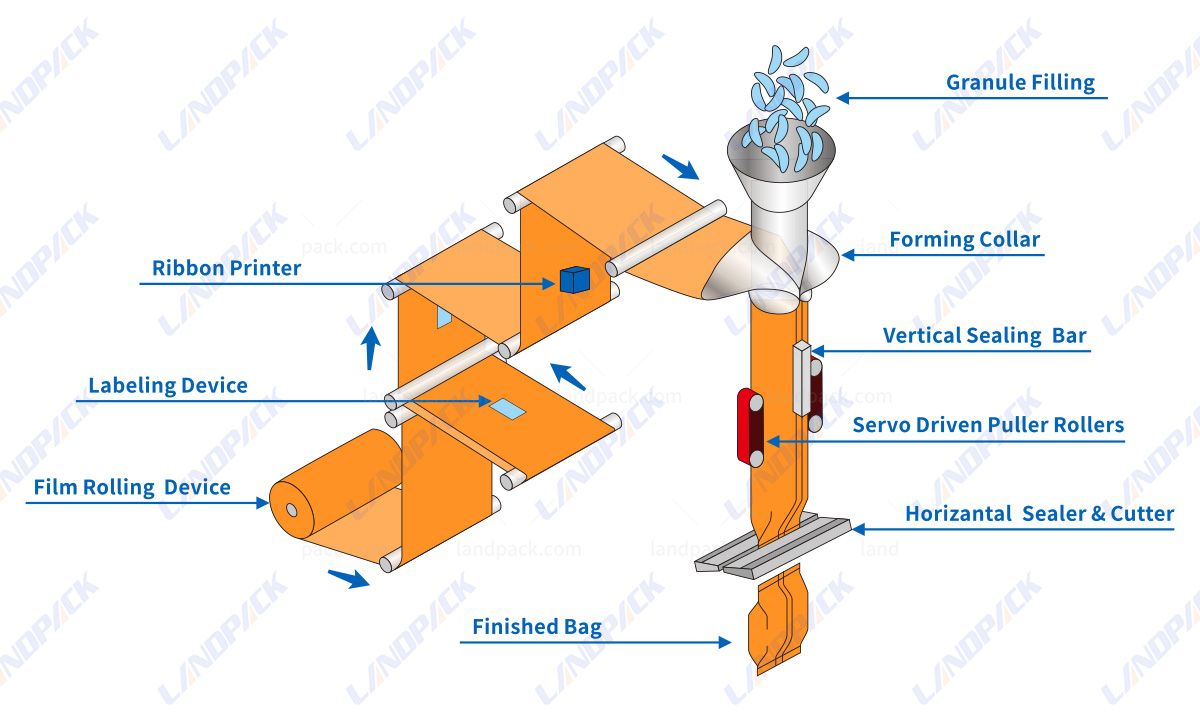

Workflow:

1. Granule Filling: Accurate gummy filling by multi-head weigher ensures consistent weight and high efficiency.

2. Forming Collar: Shapes the film into bags with neat and uniform appearance.

3. Ribbon Printing: Prints batch number and expiry date clearly on the film.

4. Labeling: Automatically applies labels precisely, saving labor time.

5. Film Rolling: Feeds film smoothly for stable and continuous packaging.

6. Vertical Sealing: Creates firm vertical seals to keep gummies fresh.

7. Servo Driven Pulling: Controls film tension and ensures accurate bag length.

8. Horizontal Sealing & Cutting: Seals and cuts bags automatically with clean finish.

9. Finished Bag Output: Delivers well-sealed, neatly labeled, and ready-to-sell gummy packages.

Machine Key Components:

1. Z Type Material Conveyor

2. Multi Heads Weigher

3. Support Platform

4. Vertical Packing Machine

5. Output Feeding Conveyor

Features:

Z Type Material Conveyor Efficient material transport design smoothly delivers gummies from the hopper to the weighing system, reducing spillage and blockages, ensuring continuous production. |  |

| Touch Screen Intelligent HMI interface allows easy setting of packaging parameters and real-time production monitoring, making operation simple and efficient. |

Multi Heads Weigher The high-speed, precise multi-head weighing system assures the precision of each bag, which reduces the amount of waste and ensures consistency. |  |

| Vertical Packing Machine |

Sealing Structure The robust sealing mechanism guarantees waterproof, leak-proof packaging that is moisture-proof, keeping freshness and quality. |  |

| Output Feeding Conveyor Automatically conveys finished products to the next process or collection station, reducing manual handling and increasing overall production efficiency. |

| Model | LD-420 | LD-520 | LD-720 | LD-900 | LD-1050 | LD-1200 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 100-800mm | 100-1000mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-505mm | 290-580mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | 400mm | 400mm | 400mm |

| Pakaging Rate | 5-60 bags/min | 5-60 bags/min | 5-55 bags/min | 5-20 bags/min | 5-20 bags/min | 5-20 bags/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm | Max.900mm | Max.900mm | Max.1200mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml | 1-25L | 1-25L | 1.5L-45L |

Get Price & More Detail