Automatic Packaging Machine For Gummy Bear

Model: LD-320SF

Application:

The Automatic Packaging Machine for Gummy Bear is specially designed for fast and accurate packaging of gummy candies, vitamin gummies, and gummies. With an advanced servo-driven system and intelligent weighing control, the machine can reach a packing speed of up to 100 bags/min, ensuring both efficiency and precision.

Application:

Its Automatic Packaging Machine for Gummy Bear was specifically designed to ensure quick and precise packaging of gummy candy as well as vitamin gummies and Gummies. Utilizing a high-end servo-driven technology and a sophisticated weighing control system, this machine can reach the speed of packing 100 bags/min which guarantees accuracy and efficiency. The Gummy Bear packaging machine incorporates automated feeding, packing, weighing, cutting, and sealing into a single unit drastically reducing the cost of labor and waste material. Touch screen technology permits simple parameter adjustments, and high-precision sensors ensure constant bag quality and smooth production.

Package Type:

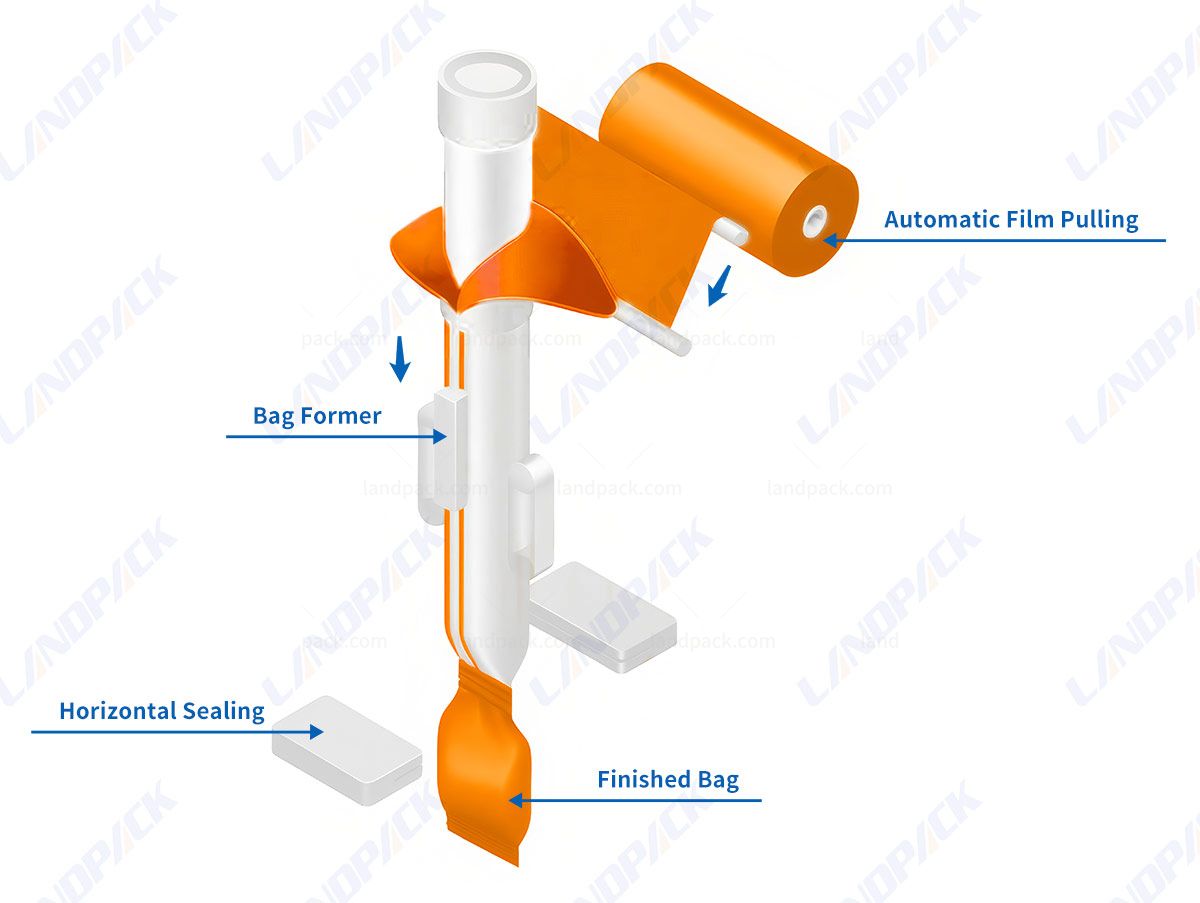

The integrated Vertical Form Fill Seal (VFFS) system efficiently converts film rolls into various bag styles, including back-sealing bags, pillow bags, gusseted bags, and quad-seal bags.

Suitable Products:

The Gummy Packaging Machine is designed to handle a wide range of granular and irregular-shaped products in the food, snack, and confectionery industries. It ensures high precision, stable sealing, and perfect bag appearance for different product types.

It is suitable for:

- Nuts & Dried Fruits: Almonds, Cashews, Cranberries, Apricots, and other dried fruits.

- Confectionery & Snacks: Gummies, Candies, Popcorn, and Biscuits - ideal for both soft and crunchy products.

- Other Granular Products: Breakfast Cereals, Beans, Pet Food, and Desiccant Beads.

Whether for small candies, vitamin gummies, or mixed nuts, this machine provides efficient and hygienic packaging solutions, keeping every product fresh, attractive, and ready for retail.

Workflow:

1. Automatic Film Feeding: Packaging film is removed from the film roll before being effortlessly fed into the machine to ensure continuous operation.

2. Bag Forming: This film goes over the forming tube and is then formed into a circular pouch. The side seam is sealed.

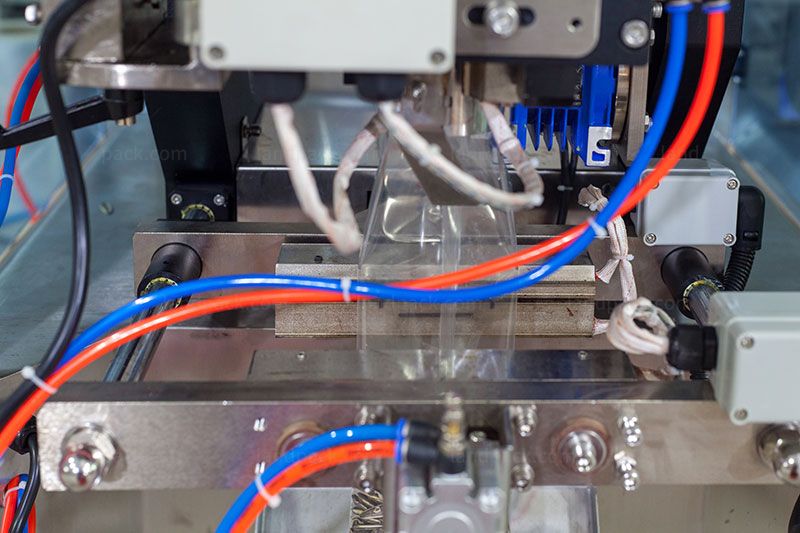

3. Horizontal sealing: The jaws are closed to create the seal on the bottom of the bag, while at the same time sealing over the top seal of the bag that was previously sealed.

4. Finalized bags output: The sealed pouch is then cut off and released, ready for next step packaging.

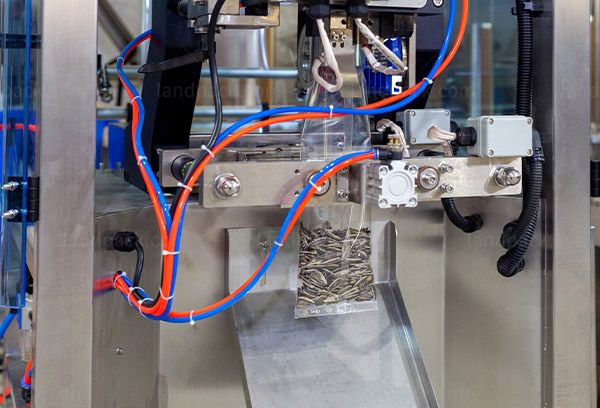

Machine Key Components:

1. Z Type Material Conveyor

2. Storage Hoppe

3. Volumetric Cups to Measure

4. Form Structure

5. Control Panel

6. Sealing Structure

Features:

Z Type Material Conveyor Lifts gummy bears smoothly from the feeding station to the weighing hopper without causing damage or sticking. The Z-type design saves floor space and ensures a continuous, efficient material supply. |  |

| Storage Hopper Used as a buffer for Gummy bears before measuring. Made from food-grade stainless steel, it guarantees hygiene, simple cleaning and stable feeding throughout the operation. |

Volumetric Cups to Measure Equipped with adjustable measuring cups for precise and consistent filling by volume. Ideal for gummy bears and other uniform granules, ensuring each bag has the correct quantity. |  |

| Form Structure |

Control Panel Smart touch-screen interface allowing easy parameter setting, production monitoring, and real-time adjustment. User-friendly design reduces operator training time. |  |

| Sealing Structure Adopts temperature-controlled horizontal and vertical sealing units to create strong, airtight seals. Keeps gummy bears fresh, prevents leakage, and enhances the bag's retail appearance. |

| Model | LD-320SF |

| Capacity | 20-100 bags/min |

| Bag size | L: 50-170mm, W: 50-150mm |

| Film width | 120mm-320mm |

| Film thickness | 0.05-0.12mm |

| Control system | PLC+Servo Motor+Color Touch Screen; PLC+Servo+Touch screen |

| Power supply | 1N+PE/50HZ/AC220V 4KW |

| Airconsumption | 0.6-0.8Mpa, 0.3-0.5㎥/h |

| Dimension | L1350*W900*H1400mm |

| Equipment Material | Main body 3mm thickness 304 stainless steel frame |

| Weight | 350kg |

| Description of Main Packaging Process | Pulling film-coding-bag making-measurement-filling (inflating)-sealing (punching)-cutting-packaging finished product output. |

Get Price & More Detail