Vitamin Gummy Counting Packaging Machine Filling Line

Application:

High-precision vitamin gummy packaging machine designed for counting and filling gummies, vitamins, and granules into bottles or jars. Reliable performance at 30 bags/min from trusted gummy packaging machine manufacturers for food and nutraceutical industries.

Application:

Vitamin Gummy Counting Packaging Machine Filling Line is an entirely automated machine designed to ensure accurate counting as well as the filling and packaging of a range of gum products, including vitamin Gummies, gummies, jelly Gummies, and small granules. Utilizing the latest technological advancements in electronic count technology as well as precise control of filling, ensures the same dosage, a clear operation, and consistent packaging quality. It operates at a steady speed of 30 bags/min. This line is perfect for the pharmaceutical, nutraceutical or food and supplement industry.

Package Type:

It is the Vitamin Gummy Packaging Machine Line is designed to handle a wide variety of container types, such as plastic (PET/PP) bottles, glass bottles, and aluminum bottles. No matter if you're making use of square, round, or custom-designed bottles, this system will ensure seamless bottle feeding, accurate weighing, and fast sealing. With a capacity of 30 bottles/min, it provides steady performance, high accuracy and reliable results for today's gummy packaging processes.

Suitable Products:

This Vitamin Gummy Counting Packaging Machine Filling Line is specifically designed to work with a range of semi-soft and solid products in the nutraceutical food and pharmaceutical industries. Its sophisticated counting and filling process assures precision and safe handling of fragile substances, ensuring form as well as quality during the entire process.

It is perfect for:

- Hard Gelatin Capsules & Soft Gel Capsules

- Tablets, Pills, and Effervescent Tablets

- Gummy, Gummies, and Candy

- Spirulina, Dietary Supplements, and Herbal Capsules

- Caffeine Capsules and Mineral Products

This machine is a great solution for gummy or capsule manufacturers who require an efficient output, hygiene-friendly production, and exact control of the product throughout every packaging process.

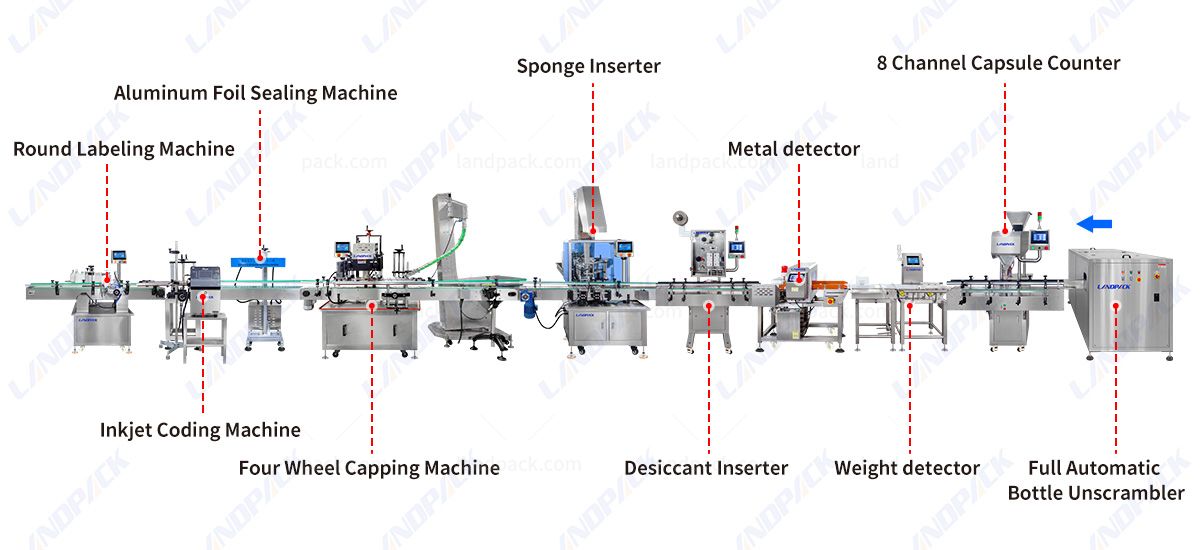

Workflow:

It is an Automated Gummy Bottle Filling Machine that provides the complete solution for filling, weighing and sealing gummy candies with the highest accuracy and hygiene. This is how it's executed step-by-step:

1. Bottle Unscrambling: Empty bottles will be aligned before being loaded onto the conveyor to ensure continual efficient production.

2. 8-Channel Counting: High-speed electronic counter precisely measures every Gummy, making sure that there are exact amounts inside every bottle.

3. Weight-checking: Every bottle that is filled is tested by using a weight detector to ensure consistency in the high-quality of the product.

4. Metal detection: Bottles go by an electro-detector which removes the possibility of contamination, ensuring that the product is safe.

5. Desiccant Insertion: Desiccant Sachets are inserted automatically into each bottle to keep the Gummies fresh and free of moisture.

6. Sponge Insertion: Soft sponges can be inserted to prevent gummies from breaking in transport or handling.

7. Four-Wheel Capping System: The capping system locks each bottle with an impervious cap that is leak-proof.

8. Aluminum Foil Sealing: Induction sealing consists of using an aluminum foil to provide an airtight, tamper-evident, and waterproof shield.

9. The Inkjet Coder: Product details such as Batch number, expiry times as well as batch number are recorded to guarantee the tracking.

10. Labeling: They are carefully put in place, giving every bottle a stylish and professional appearance.

Machine Key Components:

1. Automatic Bottle Unscrambler

2. 8 Channel Counter

3. Weight Detector

4. Metal Detector

5. Desiccant Inserter

6. Sponge Inserter

7. Four Wheel Capping Machine

8. Aluminum Foil Sealing Machine

9. Inkjet Coding Machine

10. Round Bottles Labeling Machine

Features:

Automatic Bottle Unscrambler Automatically organizes empty bottles onto production lines in a tidy and continuous manner, which ensures an efficient and stable operation, without any manual handling. |  |

| 8 Channel Counting filling machine Featuring ultra-fast photoelectric sensors. This counter precisely measures tablets, gummies or capsules, guaranteeing exact quantities in every bottle, with the least amount of errors. |

Weight Detector Real-time weigh checking system assures that each bottle meets the standard of filling, which automatically refuses to fill any underfilled or overfilled bottles. |  |

| Metal Detector |

Desiccant Inserter Automatically inserts desiccant bags inside each bottle to ensure the freshness of the product, prolong shelf life, and avoid the damage caused by moisture. |  |

| Sponge Inserter Lays a sponge on top of tablets or gummies to stop breaking or moving during transport and storage. |

Four Wheel Capping Machine Features four wheel with torque controls for speedy and secure tightening of caps on different bottles and materials, preventing leakage while giving a neat finish. | |

| Aluminum Foil Sealing Machine Uses electromagnetic induction to securely close bottle openings with aluminum foil. This provides excellent airtight protection from water and contamination. |

| Inkjet Coding Machine Prints precise, permanent dates of production batch numbers, batch numbers or expiration codes directly onto bottles for easy traceability and conformity. |  |

| Round Bottles Labeling Machine Applies labels quickly and precisely onto round bottles giving them an elegant appearance while increasing the visibility of your brand. |

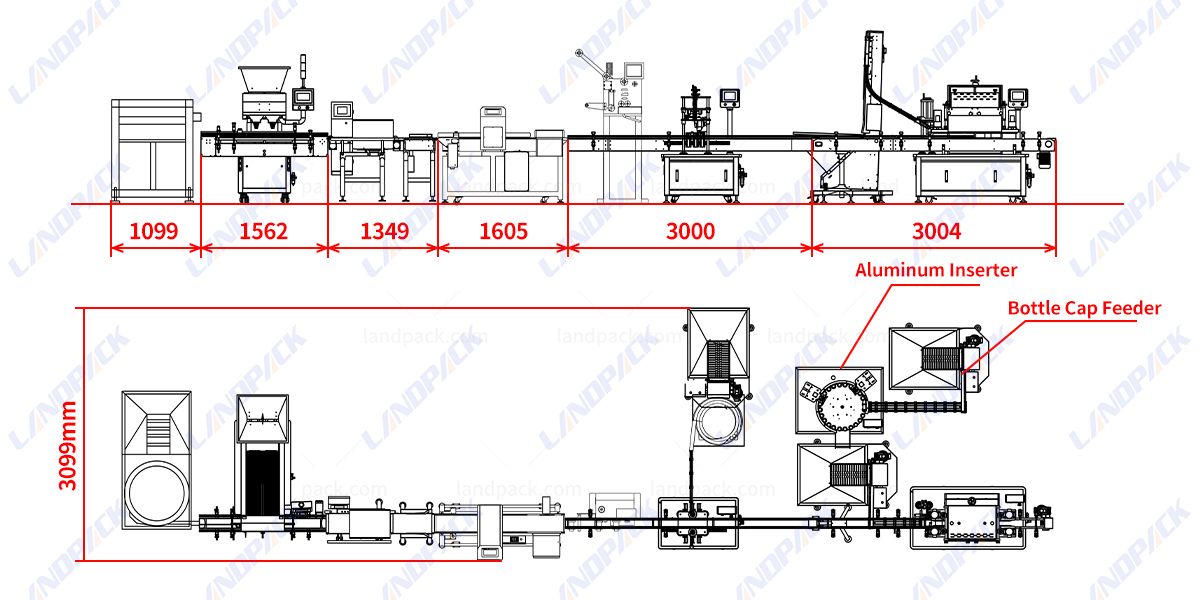

| Automatic Bottle Unscrambler | ||

| Bottle size range | 15-300 ml | |

| Power | 0.50 KW | |

| Air pressure/supply | 0.5 MPa / 0.2 m³/h | |

| Dimensions (L×W×H) | 1006×1506×1200 mm | |

| Weight | 260 kg | |

| Bottle diameter range | 30-85 mm | |

| Output | up to 260 bottles/min | |

| Power consumption | 3.4 KW | |

| Compressed air | 3.5 cfm (≈ 100 L/min) | |

| 8-Channel Capsule Counting Machine | ||

| Output / Bottles per min | up to 50 bottles/min | |

| Counting Accuracy / Precision | > 99.80 % | |

| Power / Voltage | 0.6 kW, 380 / 220 V, 50 Hz Richpacking | |

| Net Weight | 360 kg | |

| Capacity | 10–30 bottles/min | |

| Counting range | 1–999 grains | |

| Tablet / Capsule size | Tablet: 3–22 mm, Capsule: 00–5 | |

| Air pressure & consumption | 0.4–0.6 MPa, ~120 L/min | |

| Overall size | 1800*1300*1600 mm | |

| Desiccant Bag Dispenser | ||

| Insertion Speed | 60-150 bottles/min (depending on model & sachet size) | |

| Sachet Type | Single strip or continuous roll, paper/film sachets | |

| Sachet Size Range | Length 20-60 mm; Width 15-30 mm (customizable) | |

| Bottle Size Range | Diameter 30-120 mm; Height up to 250 mm | |

| Cutting & Feeding | Automatic sachet cutting, positioning, and inserting | |

| Insertion Accuracy | ≥ 99.8% | |

| Control System | PLC with touch screen operation | |

| Power Supply | AC 220 V, 50/60 Hz, 1.0 kW | |

| Air Requirement | 0.4-0.6 MPa, ~100 L/min | |

| Machine Weight | 300-400 kg | |

| Metal Detector | ||

| Metal detection tunnel size | 200 mm (W) × 150 mm (H) | |

| Continuous weighing range | 6-600 g | |

| Weighing accuracy | ±0.3 g | |

| Max throughput | 120 containers/min | |

| Detection sensitivity (no product) | Fe ≥ 0.8 mm, Non-Fe ≥ 1.0 mm, SS ≥ 1.2 mm | |

| Checkweigher range | 20-5,000 g | |

| Accuracy | ±0.02 g | |

| Max product width/height | up to 290 mm width, 5-280 mm height | |

| Weight detector | ||

| Weighing Range | 1 g - 6,000 g | |

| Accuracy | ±0.2 - ±0.5 g (depending on product & speed) | |

| Max Throughput | 100 - 400 pcs/min | |

| Conveyor Speed | 2 - 60 m/min, adjustable | |

| Conveyor Width | 50 - 600 mm (customizable) | |

| Resolution | 0.01 g / 0.1 g / 0.5 g (optional) | |

| Reject Mechanism | Air blast, pusher, drop gate, or swing arm | |

| Power Supply | AC 220 V, 50/60 Hz | |

| Air Requirement | 0.5 - 0.7 MPa (for reject device) | |

| Machine Dimensions | Approx 1200 × 710 × 750 mm | |

| Sponge dispenser | ||

| Insertion speed | e.g. 100-200 bottles/min | |

| Insertion accuracy | e.g. ±1 mm or better | |

| Bottle neck/mouth diameter range | customizable, e.g. 15–50 mm | |

| Power & pneumatic | e.g. 220 V / 50 Hz, air 0.4–0.6 MPa | |

| Aluminum foil sealing machine | ||

| Model | LD-ZS(Double Heads Aluminum Foil Sealing) | LF-LB-2000(Single Heads Aluminum Foil Sealing) |

| Applicable bottle diameter | Φ10-200mm (Could be customized) | Φ10-200mm (Could be customized) |

| Applicable bottle height | H:40-300mm (Could be customized) | H:40-300mm (Could be customized) |

| Speed | 0-30 bottles/min | 0-10 bottles/min |

| Bottle material | Glass, ceramics, plastics, metals | Glass, ceramics, plastics, metals |

| Voltage | 220V,50HZ | 220V,50HZ |

| Power | 1500W | 1200W |

| Dimension | 1500*800*1750mm | 1200*600*1550mm |

| Bottom Inkjet Coding Machine | ||

| Printing speed | 1024 seconds(5*7) | |

| Power | 220V/50HZ,150VA | |

| Printing direction | Positive sequence/reverse order/reverse/reverse | |

| Printing distance | The nozzle and the object to be sprayed are kept within 3cm | |

| Store information | The system can store 1000 print information | |

| Ink consumption | 70 million words per print | |

| Machine weight | 48kg | |

| Automatic Labeling Machine | ||

| Model | LFT-LG-100(Low speed labeling) | LFT-GS-100(High speed labeling) |

| Label length | 20mm~300mm | 20mm~300mm |

| Label width/height | 20mm~200mm(can be customized) | 20mm~200mm(can be customized) |

| Bottle width | 30-150mm(can be customized) | 30-150mm(can be customized) |

| Roll Label outer diameter | 300mm | 300mm |

| Roll Label inner diameter | 76mm | 76mm |

| Accuracy | ±1mm | ±1mm |

| Label speed | 40-100pcs/min | 60-120pcs/min |

| Conveyor speed | 5~25m/min | 15~20m/min |

| Suitable label type | Adhesive sticker label(transparent label need customized) | Adhesive sticker label(transparent label need customized) |

| Working air pressure | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Voltage | 220V can be customized 4KW | 220V can be customized 4KW |

| Weight | 350KG | 450KG |

| Overall dimension | 3000mm×1450mm×1950mm | 3050mm×1550mm×1950mm |

Get Price & More Detail