Automatic Gummy Vertical Packing Machine with Measuring Cup

Model: LD-420C

Our Vertical Form Fill Seal (VFFS) Granule Bagger is designed for high-accuracy, high-speed packaging. Perfect for free-flowing products.

Application:

Boost efficiency with our Vertical Granule Packaging Machine. Precision volumetric or weigher filling for granular products like gummy, rice, sugar, popcorn, dry food and nuts.

Application:

This Vertical Granule Packaging Machine expertly handles diverse free-flowing materials, including food items like gummy, candy, coffee beans, pet food, rice, sugar, beans, seeds, and snacks, along with non-food granular products such as detergents and fertilizers. Achieve precise, high-speed, and reliable packaging across multiple industries.

Package Type:

Our machine provides maximum shelf appeal by creating diverse bag styles. Easily produce classic Pillow bags, Gusseted bags, Flat/Block Bottom bags for stable display, Quad Seal bags for premium presence, and convenient Stand-Up Pouches.

Suitable Products:

The automatic gummy packing machine is designed to handle a range of irregularly shaped and granular products that are used in the food, snack and confectionery industry.

It is suitable for:

-Snack & Confectionery Products: gummies, popcorn, corn chips, chocolate, biscuits.

-Nuts, Seeds & Dried Fruits: almonds, cashews, peanuts, sunflower seeds, banana chips, dried apricots.

-Grains, Cereals & Frozen Foods: rice, coffee beans, peas, oats, pasta, frozen snacks.

-Non-Food & Industrial Products: pet food, fish feed, hardware, rubber parts, detergent powders.

Workflow:

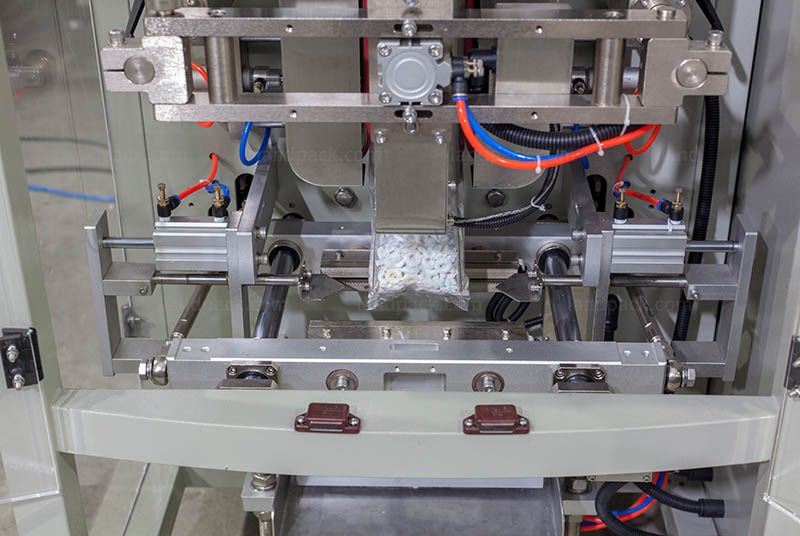

Forming Collar: Film is shaped from a flat roll into a continuous tube.

Ribbon Printer: Prints date, lot codes, or batch numbers onto the film.

Vertical Sealing Bar: Seals the back seam of the film tube.

Servo-Driven Puller Rollers: Accurately pull the film tube downwards to control bag length.

Filling System (Volumetric/Cup Filler): Granular product is dispensed into the formed bag.

Horizontal Sealer & Cutter: Seals the top and bottom of the bag, and cuts it free.

Finished Bag: The accurately filled and securely sealed package is discharged.

Model | LD-420C | LD-520C | LD-720C |

| Film Width | Max.420mm | Max.520mm | Max.720mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm |

| Roll Diameter | Max.320mm | Max.320mm | Max.320mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Measuring Range | 150-1500ml | 2000ml | 4000ml |

| Packing Speed | 5-60bag/min | 5-60bag/min | 5-55bag/min |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW | 220V 50/60Hz 3KW |

| Machine Size(L*W*H) | 1217*1015*1343mm | 1488*1080*1490mm | 1780*1350*2050mm |

| Machine Weight | About 650kg | About 680kg | About 750kg |

| Option Device | 1.Date Printing, 2.Hole Punching Device(Pinhole, Round hole, the butterfly hole), 3.Air-filling Device, 4.Tear Notch Device | ||

Machine Key Components:

1. Z Type Material Conveyor

2. Volumetric Cups To Measure

3. Control Panel

4. Packing Machine

5.Finished Product Output

Feature:

Z Type Material Conveyor Lifts gummy bears smoothly from the feeding station to the weighing hopper without causing damage or sticking. The Z-type design saves floor space and ensures a continuous, efficient material supply. |  |

| Storage Hopper Used as a buffer for Gummy bears before measuring. Made from food-grade stainless steel, it guarantees hygiene, simple cleaning and stable feeding throughout the operation. |

Volumetric Cups to Measure Equipped with adjustable measuring cups for precise and consistent filling by volume. Ideal for gummy bears and other uniform granules, ensuring each bag has the correct quantity. |  |

| Form Structure |

Control Panel Smart touch-screen interface allowing easy parameter setting, production monitoring, and real-time adjustment. User-friendly design reduces operator training time. |  |

| Sealing Structure Adopts temperature-controlled horizontal and vertical sealing units to create strong, airtight seals. Keeps gummy bears fresh, prevents leakage, and enhances the bag's retail appearance. |

Get Price & More Detail