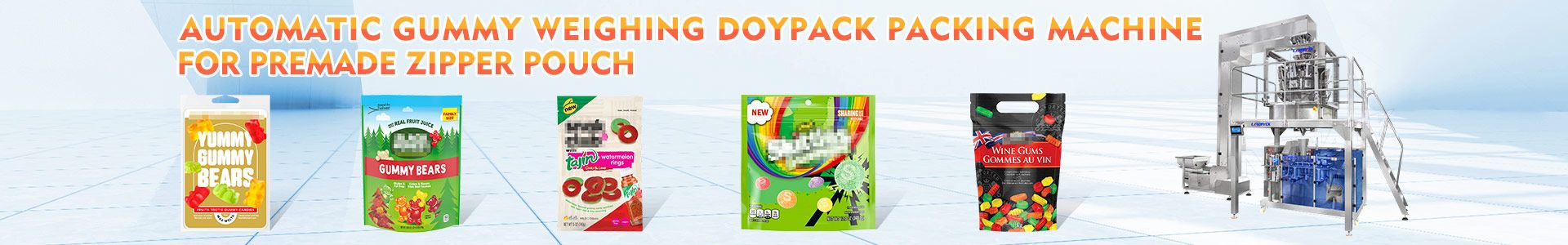

Automatic Gummy Weighing Doypack Packing Machine for Premade Zipper Pouch

Model: Gummy Weighing Doypack Packing Machine

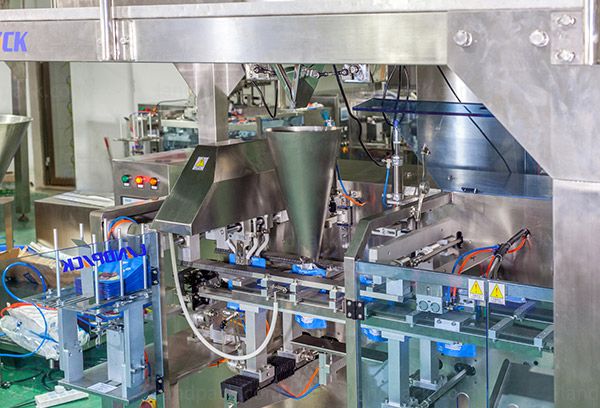

The GP-210A is a fully automatic horizontal doypack packing machine designed for packing gummy candies in premade pouches. With a stainless-steel dust cover that guarantees an hygienic and clean production area while also stopping sugar particles and other waste from getting into the system.

Application:

The machine is used primarily to pack gummy candy such as fruit chews, jelly sweets Vitamin gummies, as well as other soft confectionery items. It also handles similar products like marshmallows, chocolate, and sugar-coated confectionery with reliable performance and smooth operation.

Application:

The machine is used primarily to pack gummy candy such as fruit chews, jelly sweets Vitamin gummies, as well as other soft confectionery items. It also handles similar products like marshmallows, chocolate, and sugar-coated confectionery with reliable performance and smooth operation.

Suitable Products:

The machine is suited to pack various snacks and confectionery items, such as gummy candies such as fruit chews, jelly drops soft toffees, vitamin Gummies, and collagen candy. It is also able to be used to small-sized solid food items that have similar characteristics, which ensures an accurate filling process and perfect sealing of the pouch without affecting the texture or shape of the product.

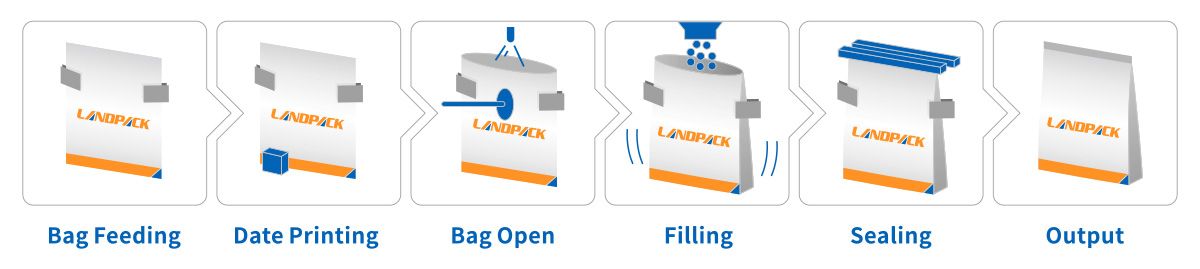

Workflow:

1. Gummy Product Conveying: Gummies are smoothly transported from the feeding system to the weighing unit through a hygienic conveyor.

2. Multi-Head Weighing: The multihead weigher accurately measures each portion, ensuring consistent weight and minimal product loss.

3. Bag Feeding: Pre-made pouches are automatically picked and positioned for filling, maintaining continuous and efficient operation.

4. Bag Opening: The machine gently opens each pouch using vacuum suction and mechanical grips, ensuring precise alignment for filling.

5. Product Filling: Measured gummy portions are discharged into the opened bags with controlled speed to prevent sticking or damage.

6. Sealing: The pouches are heat-sealed firmly and neatly, preserving product freshness and preventing leakage.

7. Finished Product Output: The sealed bags are conveyed to the output section for final inspection, packing, or downstream processes.

| Type | GP-160 | GP-160L | GP-210L | GP-260L |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

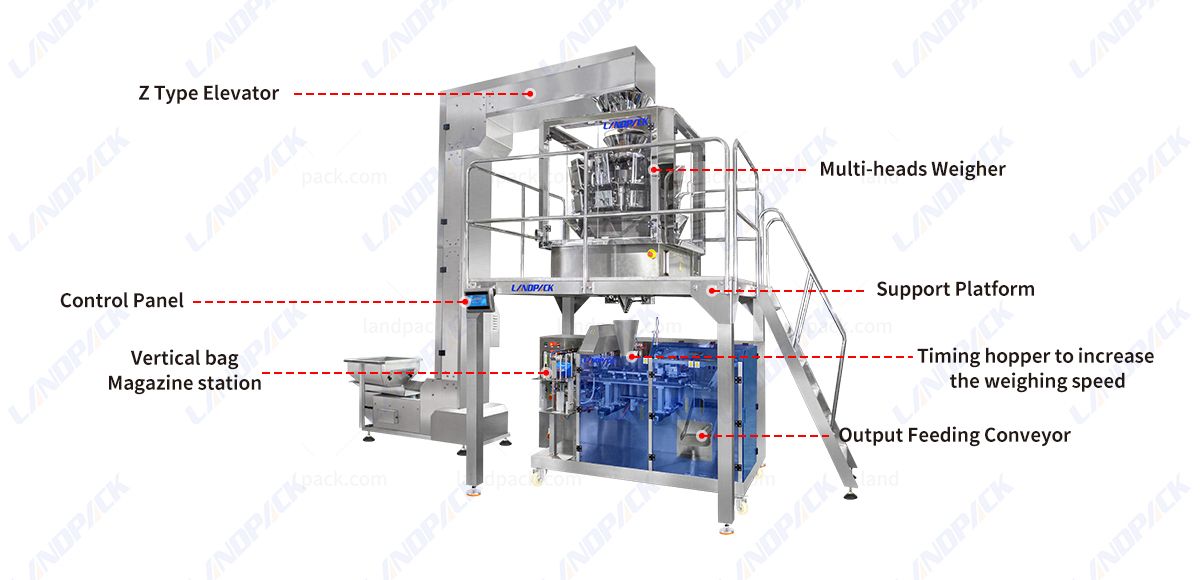

Machine Key Components:

1. Z Type Elevator

2. Multi-heads Weigher

3. Support Platform

4. Control Panel

5. Vertical bag magazine station

6. Labeling Machine

7. Timing hopper

8. Output Feeding Conveyor

Feature:

Product Conveying System Gummy candy is gently transported through a food-grade conveyor which ensures a stable and continuous feed process. The design reduces stickiness and friction while making sure the work area is tidy and neat. |  |

| Multihead Weighing Unit Equipped with a high-precision, multihead weigher, this system ensures exact dosing and quick weigh cycles. It is perfect for gummies with irregular or sticky shapes and will ensure consistency throughout each pouch. |

Automatic Bag Feeding System Premade bags are automatically pulled from magazines and placed for the next stage of production. Servo-driven arm movements ensure smooth movement and a stable bag transfer, which reduces time to complete and increasing speed of production. |  |

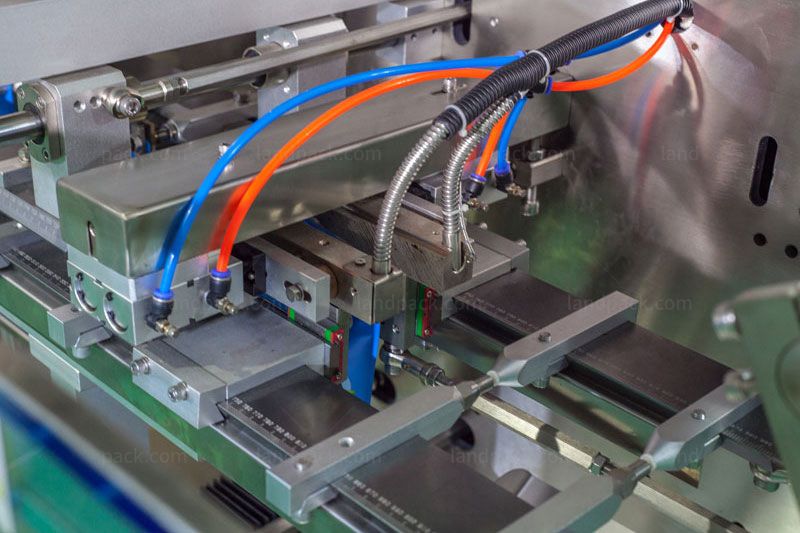

| Bag Opening Mechanism |

Product Filling Station Gummies are taken out of the weighing hopper and into the pouch using a controlled timing. The specially designed drop path stops candy deformation while maintaining the product's integrity and its visual appeal. |  |

| Sealing Unit The sealing system uses equal pressure and heat to create airtight, firm seals. The temperature is controlled automatically in accordance with different film types that ensure freshness and durability within every bag. |

Get Price & More Detail