Automatic Mixed Gummies Can Tin Filling Sealing and Labeling Machine

Model: Mixed Nuts Peanuts Can Tin Filling Line

Automate your snack packaging with our versatile granule filling line. Accurately fill up to six different products into tin cans. Features precision vacuum nitrogen flushing and airtight sealing for maximum freshness and extended shelf life.

Application:

This automated filling and sealing line handles 6 types of granular snacks like nuts, gummies, pet food, dry fruit, oatmeal, etc. It precisely fills tin cans, then uses advanced vacuum nitrogen flushing and sealing technology.

Application:

This line is specifically engineered for tin cans (metal canisters, plastic cans), utilizing a robust vacuum nitrogen flushing and sealing process to ensure an ultra-long shelf life for food products like gummies, chocolate, rices and nuts.

Suitable Products:

Our automated filling line is engineered for high-precision packaging of premium snacks, starting with delicate gummies and crunchy nuts. Beyond this, its multi-product capability is ideal for a vast range of granular and solid items, including: candies and gummies, coffee beans, confections, dried fruit pieces, cereals & granola, rice & beans, loose-leaf tea, small pasta shapes, seeds & spices, pet food, desiccant packets, etc. This system offers versatile, high-speed filling for up to six different materials into airtight tin cans, utilizing vacuum nitrogen flush and sealing technology to guarantee long-lasting freshness and superior product quality.

Workflow:

1. Bottle Unscrambler: Automatically sorts and aligns empty tin cans from bulk supply onto the conveyor belt in a single file.

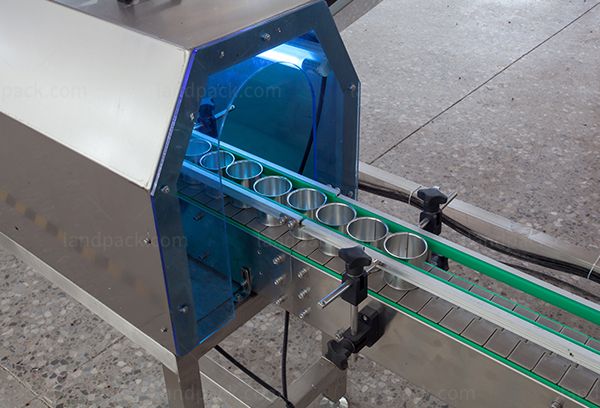

2. UV Sterilization Channel: Empty containers pass through this tunnel, using UV light to ensure a sterile environment for food safety and a longer shelf life.

3. 6 Heads Linear Weigher for weighing mixed-gummies: Precisely measures and combines the six different granular products into the exact target weight for consistent batches.

4. Straight Type Nuts Filling Machine: The straight-line filler gently and precisely dispenses the weighed mixed granules into the aligned tin cans.

5. Vacuum Seaming and Nitrogen Filling Machine: Removes oxygen (vacuum), flushes the can with nitrogen, and hermetically seals the lid to guarantee long-term freshness.

6. Round Bottle Labeling Machine: High-speed unit accurately applies pre-printed labels to the curved surface of the sealed cans for retail presentation.

7. Bottle Flip Device: Inverts the sealed cans to ensure contents are settled and to allow for a final seal inspection.

8. Finish Can Collection Table: The finished, labeled, and sealed products accumulate here for easy manual or automated transfer to final case packing.

| Linear Type Granule Filling Machine | |

| Item | Specification |

| Model | LD-6G |

| Filling Range | 50g – 2000g (customizable) |

| Filling Speed | 20 – 50 cans/min (depending on material and container size) |

| Filling Accuracy | ≤ ±1% |

| Applicable Containers | Tin cans, plastic jars, glass bottles, etc. |

| Control System | PLC & Touch Screen (English/Chinese interface) |

| Material Contact Parts | SUS304 stainless steel |

| Power Supply | AC220V / 50Hz / 1.5kW |

| Air Pressure Requirement | 0.6MPa, 0.3m³/min |

| Machine Dimension | 2000 × 800 × 1800mm |

| Machine Weight | Approx. 350kg |

| 6 Heads 999g Linear Weigher | |

| Item | Specification |

| Model | LD-6H |

| Weighing Range | 10g – 999g (per head) |

| Max. Speed | 60 weighs/min |

| Accuracy | ±0.3~1.5g (depends on product characteristics) |

| Hopper Volume | 1.6L / 2.5L (optional) |

| Feeding Method | Dual vibration feeding with digital load cell |

| Display System | 10” touch screen, programmable target weight & ratio |

| Material | Full SUS304 stainless steel (food grade) |

| Power Supply | AC220V / 50Hz / 1.0kW |

| Machine Weight | Approx. 300kg |

| Machine Dimension | 1500 × 1000 × 1300mm |

| Vacuum Seaming and Nitrogen Filling Machine | |

| Item | Specification |

| Model | LD-1 |

| Applicable Container | Tin cans, round cans, aluminum cans, plastic jars |

| Container Diameter Range | 50 – 120 mm |

| Container Height Range | 80 – 200 mm |

| Seaming Accuracy | ±0.1 mm |

| Nitrogen Filling Accuracy | Residual O₂ ≤ 3% |

| Production Capacity | 15 – 30 cans/min (depending on size and product) |

| Control System | PLC with Touch Screen (English interface) |

| Vacuum Pump | High-efficiency industrial vacuum pump |

| Seaming Heads | 1 or 2 heads (optional) |

| Material Contact Parts | Food-grade stainless steel SUS304 |

| Power Supply | AC220V / 50Hz / 2.2kW |

| Air Pressure Requirement | 0.6 MPa, 0.3 m³/min |

| Machine Dimension | 1800 × 800 × 1500 mm |

| Machine Weight | Approx. 400 kg |

| Features | Vacuum + Nitrogen filling, automatic can feeding & seaming, adjustable residual oxygen, hygienic design, easy cleaning |

| Round Bottle Labeling Machine | ||

| Model | LFT-LG-100(Low speed labeling) | LFT-GS-00(High speed labeling) |

| Labeling speed | Max 120bottle/min | Max 140bottle/min |

| Labeling accuracy | ±1mm | ±1mm |

| Label maximum width | 100mm(Could be customized) | 100mm(Could be customized) |

| Size of the object being attached | Φ30mm-Φ100mm(Could be customized) | Φ30mm-Φ80mm(Could be customized) |

| Label ID | Φ76mm | Φ76mm |

| Label OD | MaxΦ330mm | MaxΦ380mm |

| Voltage | 220V、50HZ | 220V、50HZ |

| Power | 1.5KW | 1KW |

| Weight | 250kg | 300kg |

Machine Key Components:

1. Bottle Unscrambler

2. UV Sterilization

3. 6 Heads Linear Weigher

4. Chain Conveyor Filler

5. Vacuum Seaming Machine

6. Labeling Machine

7. Bottle Filp Device

8. Finish Collection Table

Feature:

Bottle Unscrambler Fully automatic rotary sorting and single-filing mechanism. Eliminates manual labor and ensures a high-speed, continuous, and steady supply of properly oriented cans to the filling line. |  |

| 6 Heads Linear Weigher for weighing mixed gummies High-precision, multi-head linear weighing system with fine-tuning control. Achieves ultra-accurate, consistent target weights for complex mixed products, dramatically minimizing product giveaway and ensuring uniform blend quality. |

UV Sterilization Channel Integrated UV-C germicidal lamps within an enclosed tunnel. Provides critical pre-fill sanitization of empty containers, guaranteeing a sterile environment and extending the final product’s shelf stability. |  |

| Modular and Quick-Release Filling Zone Feature |

Straight Type Nuts Filling Machine Dedicated straight-line filling mechanism with product-specific tooling. Ensures gentle handling and rapid, efficient transfer of weighed granules into the cans, reducing product breakage and maximizing throughput. |  |

| Bottle Flip Device Integrated powered conveyor mechanism for 180-degree container inversion. Allows for thorough inspection of the can base or seal integrity, and aids in settling granular contents before final collation. |

Finish Can Collection Table Stainless steel accumulation/rotary table with adjustable speed control. Acts as an efficient buffer for finished product, allowing smooth transfer to downstream case-packing, preventing line blockages, and easing operator collection. |  |

Get Price & More Detail