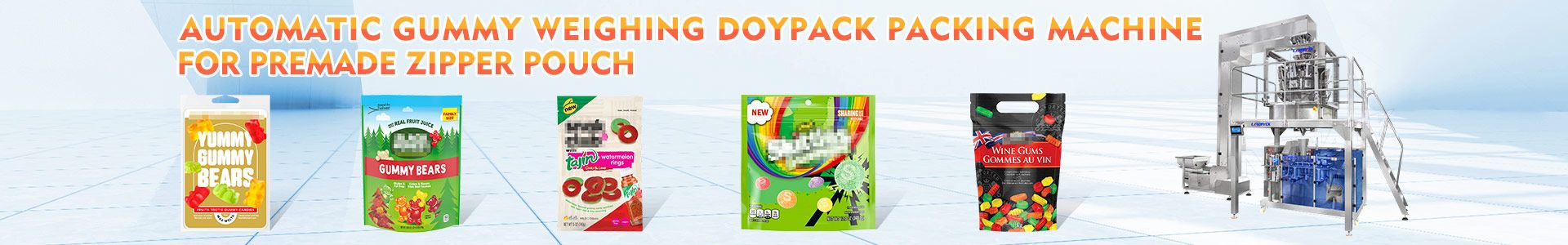

Automatic Gummy Vertical Counting Packaging Machine

Model: Gummy Weighing Doypack Packing Machine

This vertical packaging machine equipped with ten vibrating bowls is specially designed for accurate counting and filling of gummy candies. It offers smooth feeding, precise measurement, and stable bag forming at high speed. Ideal for packaging gummies, jelly candies, and other small confectionery items with consistent quality and efficiency.

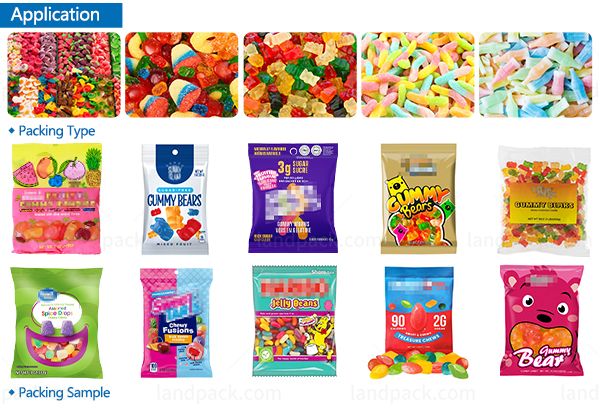

Application:

This machine is widely used in the confectionery and snack industries for packing various small and irregular products. It is ideal for gummies, jelly candies, chocolate beans, nuts, dried fruits, and similar bite-sized items.

Application:

This machine is widely used in the confectionery and snack industries for packing various small and irregular products. It is ideal for gummies, jelly candies, chocolate beans, nuts, dried fruits, and similar bite-sized items.

Suitable Products:

This machine is extremely suitable to package a variety of irregular and small-sized materials like soft chews, vitamin Gummies, coated tablets miniature biscuits, nuts and seeds that have been roasted. With 10 bowls that vibrate that ensure precise counting, gentle feeding and steady filling, keeping the product from getting damaged or stuck. The vertical form-fill seal structure is able to support diverse types of film and bag designs, providing neat, airtight and attractive packaging perfect for retail display.

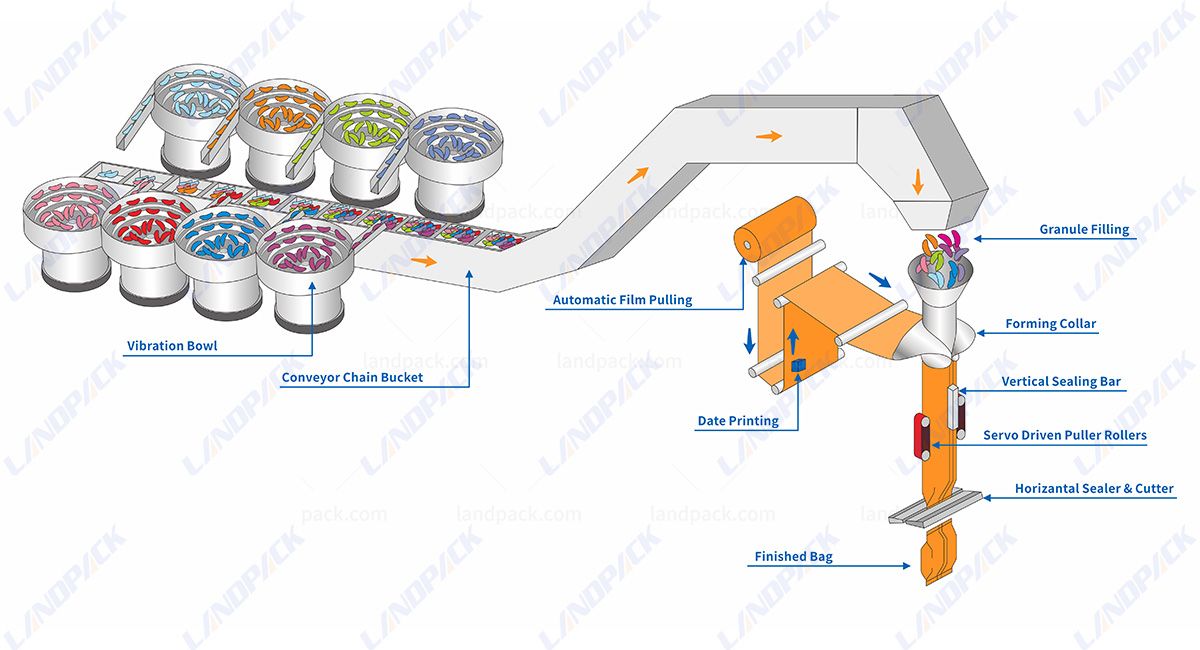

Workflow:

1. Product Feeding: Gummies or small items are evenly distributed through ten vibrating bowls for accurate counting.

2. Counting & Collecting: Counted products are gathered and transferred into the main filling system.

3. Bag Forming: The vertical machine automatically forms bags from film rolls according to the preset size.

4. Filling: Counted gummies are gently filled into the formed bags without damage or loss.

5. Sealing & Cutting: Bags are heat-sealed and precisely cut to ensure neat and airtight packaging.

6. Finished Product Output: Packed bags are discharged onto the conveyor for inspection or further packing.

| Model | LD-LS-300 | LD-LS-500 |

| Packing size | L: 30-180mm, W: 50-140mm | L: 50-300mm, W: 90-250mm |

| Max film width | 320mm | 520mm |

| Packing material | OPP, CPP, Laminated film | |

| Air supply | 0.4-0.6 MPa | |

| Packing speed | 10-50 bags/min (Depending on the counting quantity and material size) | |

| Power | AC220V or AC 380V, 2KW-6KW | |

| Machine size | Customized size | |

Machine Key Components:

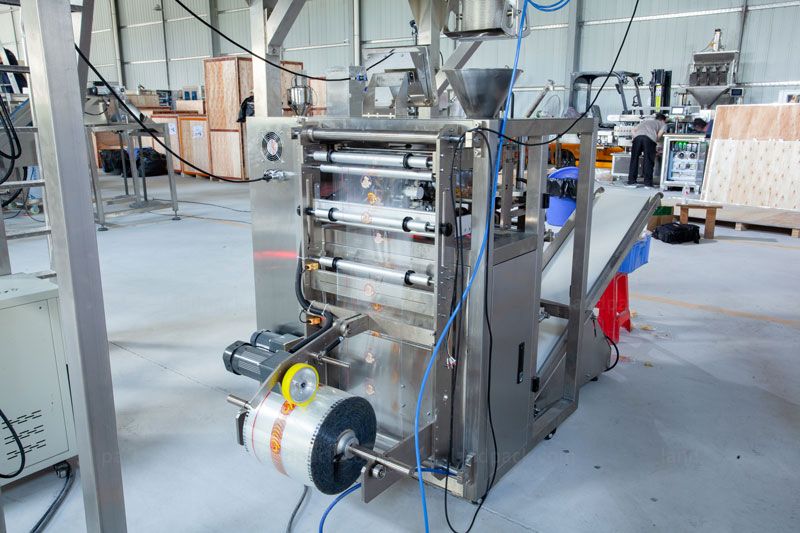

1. Packing Film

2. Packing Machine

3. Vibration Bowl

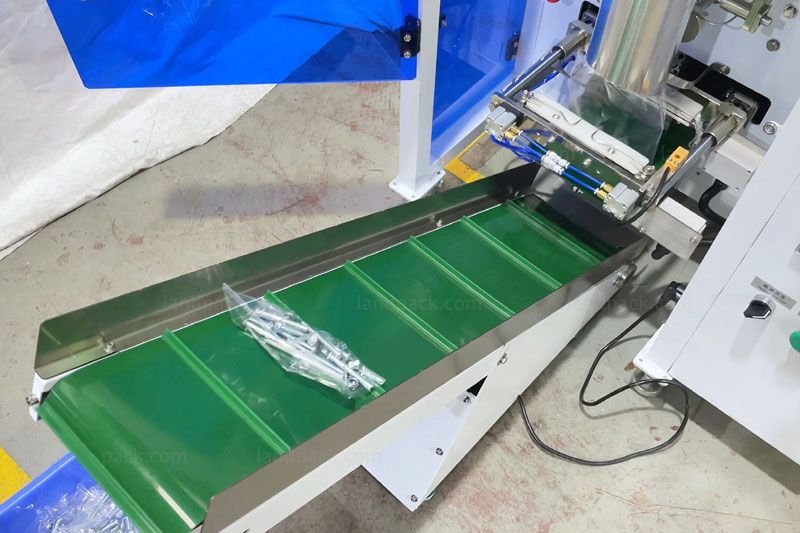

4. Finished Conveyor Belt

5. Electric Box

Feature:

Vibration Feeding Equipment Fitted 10 separate vibrating bowls that can be used for exact counting and smooth distribution of gummies. This ensures a an even distribution of the product and avoiding overflow or injury to. |  |

| Central Collecting Hopper Efficaciously collects the counted items from each bowl, and then synchronizes to the primary packing unit to ensure continuous operation and precise filling. |

Vertical Form Fill Seal Unit (VFFS) Automatically completes bag making sealing, cutting, and sealing with precision and high accuracy, able to adapt to different film types and bags sizes. |  |

| Film Pulling and Sealing Mechanism |

Screen Control Panel with Touchscreen An integrated PLC system that provides a an intuitive user interface that allows for real-time monitoring as well as parameter adjustment and diagnostics of faults. |  |

| Conveyor for Finished Product Moves bags that are sealed smoothly into the next stage and is ideal for labeling, inspection, or for packaging secondary to the original. |

Get Price & More Detail