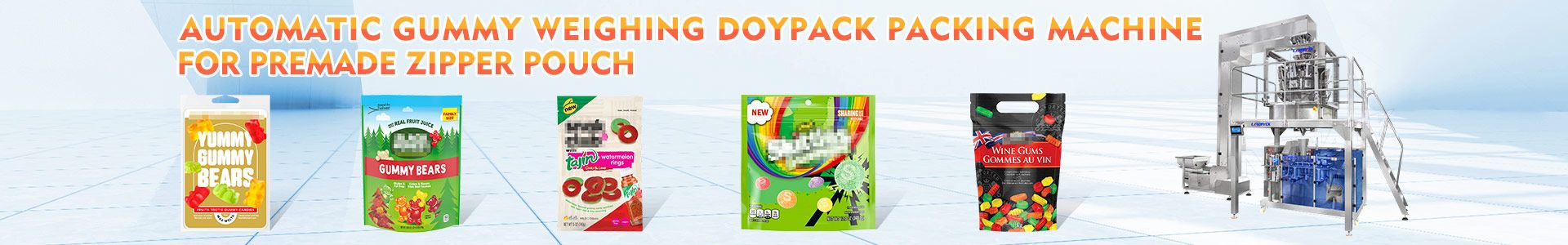

Automatic Gummy Candy Packaging Machine Rotary Pouch Packing Machine

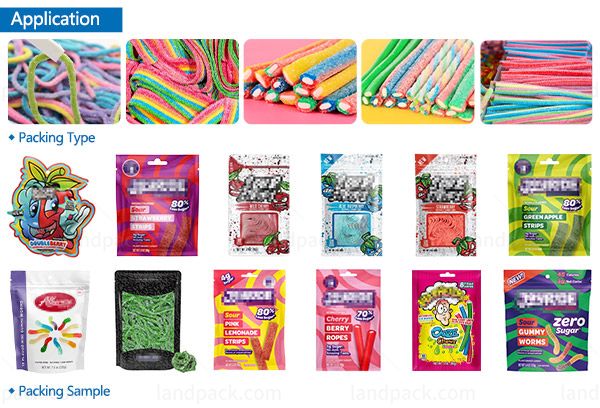

Application:

The Automatic Gummy Candy Packaging Machine (Rotary Pouch) is a fully automatic solution for fast, accurate, and hygienic gummy candy and small granule packaging. Its intelligent rotary pouch system and precise dosing ensure consistent filling and airtight sealing. With speeds up to 60 bags/min, it offers stable performance, minimal waste, and premium pack appearance—ideal for efficient confectionery production lines.

Application:

The Automatic Gummy Candy Packaging Machine Rotary Pouch Packing Machine is a fully automatic solution designed for fast, accurate, and hygienic packaging of gummy candies, jelly sweets, and other small granules. Equipped with an intelligent rotary pouch system and high-precision measuring devices, it ensures consistent pouch filling and airtight sealing for every pack.

This machine is widely used by gummy packaging machine manufacturers and candy producers who seek efficiency and product uniformity. With a packing speed of up to 60 bags/min, it delivers stable performance, minimal material waste, and premium packaging appearance - making it the perfect choice for modern confectionery production lines.

Package Type:

The Automatic Gummy Candy Packaging Machine Rotary Pouch Packing Machine is designed to handle various premade pouch styles such as doypack (stand-up pouch), flat pouch, M-shape pouch, and flat bottom pouch, making it ideal for different gummy candy packaging requirements. It supports pouches made from PET/PE, OPP/AL/PE, kraft paper, and other laminated materials, ensuring strong sealing, durability, and excellent barrier protection.

Suitable Products:

This Automatic Gummy Candy Packaging Machine has been specifically designed to handle a broad range of granular and gummy items. It provides exact measurement, precise sealing and appealing packaging for a variety of foods and confectionery.

This machine is ideal for:

- Gummy bears, fruit gummies, and vitamin gummies

- Jelly candies, soft chews, and coated candies

- Small granules, nuts, cereals, and dry fruits

- Pet treats and similar small-sized snacks

With a high-speed rotary pouch system, it can easily handle sticky or irregularly shaped candies, maintaining accuracy and freshness in every pouch. The machine's adaptability makes it a trusted solution among gummy packaging machine manufacturers and snack producers worldwide.

Workflow:

1. Giving Bag: The system automatically picks up premade pouches and accurately positions them on the rotary station for filling.

2. Coding: Each pouch is printed with the date, batch number, or production information for easy product tracking.

3. Pouch Opening: Vacuum suction gently opens the pouch, preparing it for gummy filling.

4. Product Filling: Gummies are accurately weighed and filled into each pouch, ensuring precision and minimal product waste.

5. First Pressing: The filled pouch is leveled so that gummies settle evenly before sealing.

6. Second Pressing: A second press flattens the pouch, enhancing appearance and readiness for sealing.

7. First Heat Seal: The top of the pouch is heat-sealed to prevent air and moisture from entering.

8. Final Sealing: The final seal guarantees airtight protection and a polished, professional finish.

Machine Key Components:

1. Chain Bucket Elevator

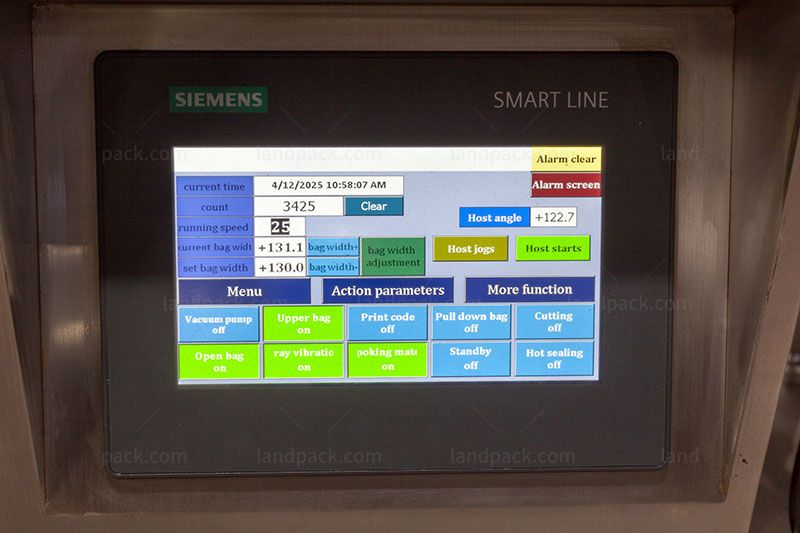

2. PLC Control Panel

3. Emergency Button

4. Bags Feeding

5. Rotary Packer

6. Finished Product Conveyor

Features:

Chain Bucket Elevator Efficiently conveys gummies or raw materials to the machine, ensuring continuous production and reducing manual handling. |  |

| PLC Control Panel Intelligent touch control for easy operation, fully adjustable parameters, enabling precise monitoring and automation. |

Emergency Button One-touch emergency stop for operator safety, preventing accidents and equipment damage. |  |

| Bags Feeding |

Rotary Packer Core packaging unit with rotary station and precise dosing, quickly filling gummies with high accuracy and neat presentation. |  |

| Finished Product Conveyor Smoothly transports packed products for stacking or boxing, maintaining continuous workflow. |

| Type | LD-8230 | LD-8260 | LD-8300 | LD-8400 |

| Bag Type | Doypack, stand up pouch, flat pouch, M shape pouch, flat bottom pouch, etc | |||

| Bag Size | 150-380mm*80-230mm (L*W) | 150-380mm/140-260mm (L*W) | 150-430mm/180-300mm (L*W) | 200-500mm/270-400mm (L*W) |

| Filling Range | 10g-1000g | 1500g | 2000g | 3000g |

| Packing Speed | 20-60 bags/min | 20-50 bags/min | 10-40 bags/min | 10-25 bags/min |

| Voltage | Standard AC380V+10%, three-phase 50HZ; | |||

| Total Power | 3.75KW | 3.75KW | 3.85KW | 4.5KW |

| Air Consumption | 0.4m³/min | |||

| Dimensions | 1740*1380*1450mm(L*W*H) | 2460*1830*1460mm(L*W*H) | 2260*2200*1520mm(L*W*H) | |

| Machine Weight | 1300KG | 1300KG | 1700KG | 2000KG |

Get Price & More Detail