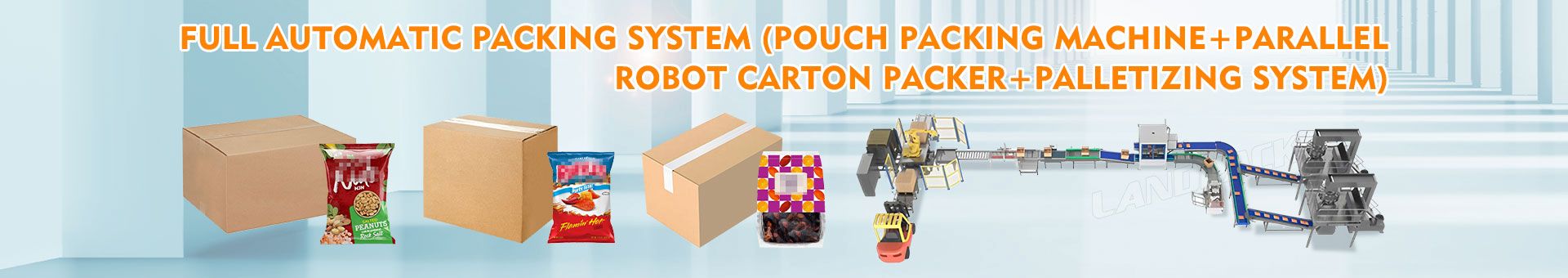

Automated Packaging System End Load Pouch Counting Cartoning Machine

Model: Automated Packaging System

This Automated Packaging System End Load Pouch Counting Cartoning Machine is designed for automatic counting, grouping, and end-load cartoning of finished pouches from upstream packaging machines.

Application:

Widely used in food, snack, pharmaceutical, health product, and daily chemical industries to pack pouches, bags, and bottles into cartons with high accuracy and consistent output.

Application:

This packing system widely used in food, snack, pharmaceutical, health product, and daily chemical industries to pack pouches into cartons with high accuracy and consistent output. Ideal for connecting with premade pouch machines, vertical packing machines, and filling lines, it significantly reduces labor costs while improving cartoning speed, packaging consistency, and overall line automation.

Package Type:

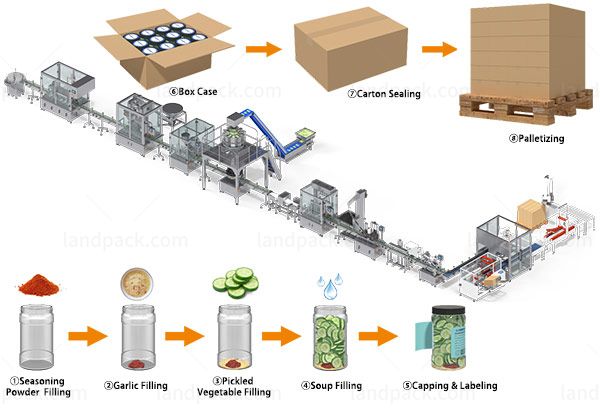

This automated packing system is designed for packing cartons, including folding cartons and standard retail cartons.

Suitable Products:

This Packing System is suitable for counting and cartoning kinds of products with different forms, including solid, granular, liquid, and semi-liquid materials. With stable conveying and accurate counting performance, it ensures efficient and reliable packing for various industries.

- Food products: biscuits, chocolate bars, wafer packs, bread and snack pouches

- Daily necessities: wet wipes, tissues, soap bars and sponge packs

- Health & personal care items: mask packs, medical wipes, sachets and small boxed supplements.

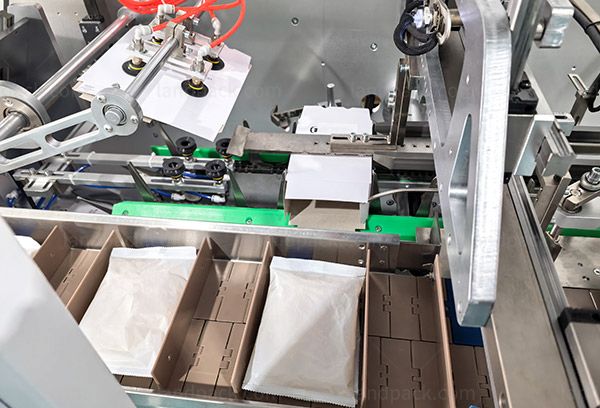

Workflow:

1. Conveying Bag Materials: Finished pouches transferred smoothly from the upstream machine to the cartoning machine.

2. Counting: Accurately counting finished pouches to meet the preset quantity for each carton.

3. Pack into cartons: Automatically loaded pouches into cartons by the end-load cartoning machine.

4. Carton Lid Sealed: Closing and sealing cartons, ready for downstream handling or palletizing.

| Model | LDDS-80 | LDDS-100 | LDDS-220 |

| Packing Speed | 40-60 cartons/min | 30-50 cartons/min | 30-50 cartons/min |

| Box Size | L: 60-220mm, W: 20-125mm, H: 15-60mm | L: 80-250mm, W: 100-160mm, H: 40-90mm | L: 150-320mm, W: 100-180mm, H: 90-110mm |

| Air Consumption | ≥0.6 mpa, 20 m³/h | ||

| Power Supply | 220V/380V, 50HZ | ||

| Machine Power | 4.5KW | 5.5KW | 6.5KW |

| Machine Size | 3425*1390*1771mm | 3450*1450*1800mm | 4200*1650*1850mm |

| Machine Weight | 1200KG | 1600KG | 2500KG |

Machine Key Components:

Feature:

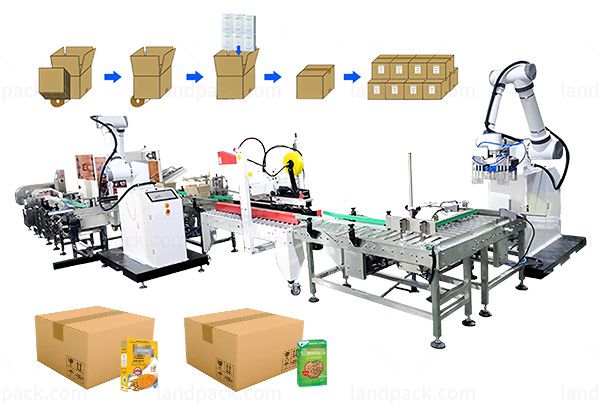

1. End-Side Pushing Design: Ensures stable and precise product loading, especially suitable for stackable and regularly shaped products.

2. Servo-Driven Control: The servo-driven control system offers exact motion and smooth control and quick speed adjustments.

3. Automatic Carton Handling: Automated carton erecting and closing enhances efficiency and minimizes intervention by hand.

4. Product & Carton Detection: Carton presence and detection of products screening to prevent missing or empty product cartons.

5. Quick Changeover: User-friendly design allows fast and easy adjustment for different product and carton sizes.

6. Compact & Flexible Layout: Space-saving structure with stable output, ideal for seamless integration with VFFS machines, flow wrappers, doypack machines, multi-lane packing machines, and filling systems.

Get Price & More Detail