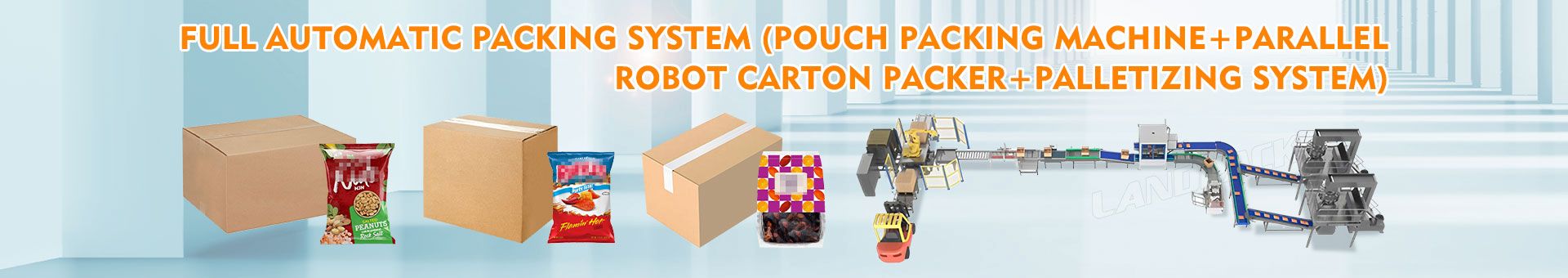

Automated Intelligent Powder Weighing Case Packing System

Model: Case Packing System

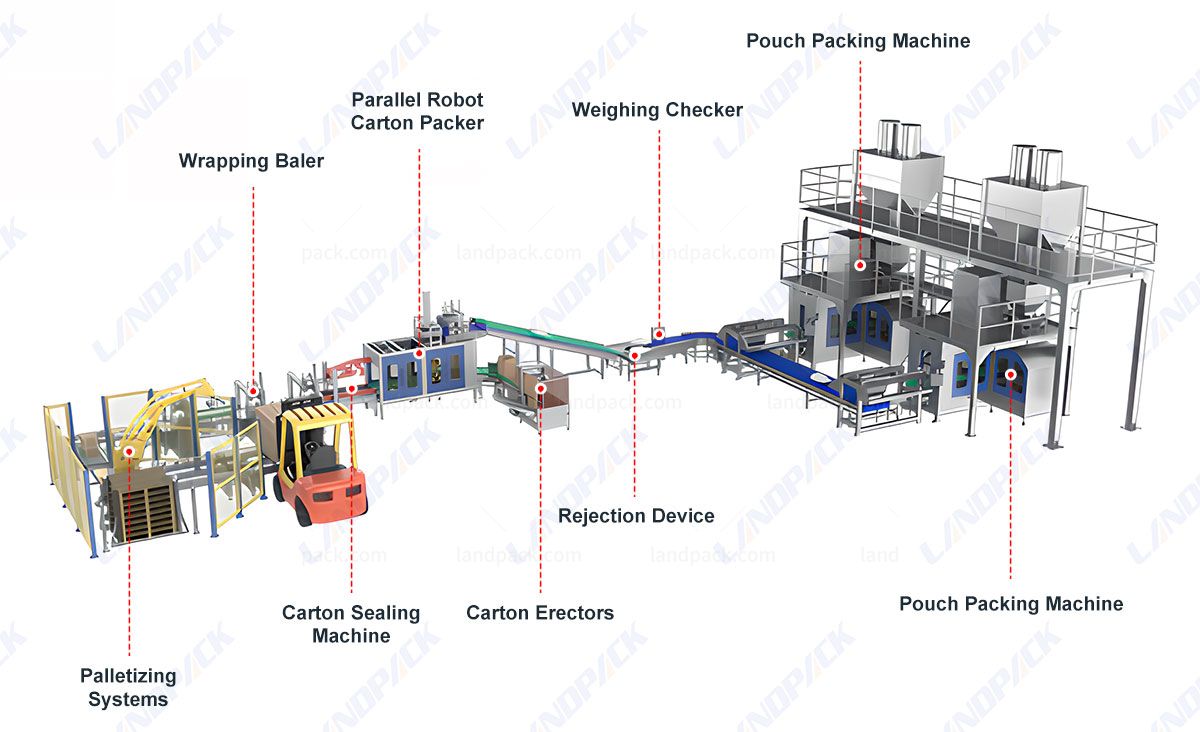

This automatic cartoning line for bagged powder is made up of a vertical packing machine set, a checkweigher, a one-to-two intelligent cartoning robot, a case erector, a case sealer, and a palletizing robot.

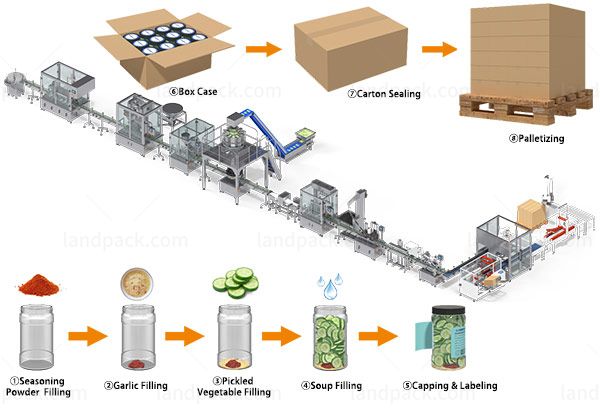

Application:

Packaging system for powder material such as powder products, including milk powder, coffee powder, spice powder, protein powder, nutritional supplements, pharmaceutical powders, and meal replacement powders.

Application:

Packaging system for powder material such as powder products, including milk powder, coffee powder, spice powder, protein powder, nutritional supplements, pharmaceutical powders, and meal replacement powders.

Package Type:

Engineered for high-speed versatility, this multihead weighing and VFFS line automatically forms, fills, and seals a wide range of bag styles from roll film. It is fully compatible with pillow bags, gusseted pouches, flat-bottom bags, and quad-seal formats, offering a seamless solution for diverse flexible packaging needs.

Suitable Products:

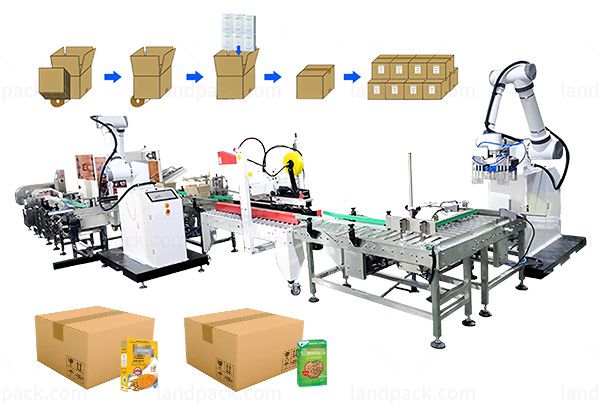

The line uses our self-designed high-speed, flexible parallel robot for picking and placing. This ensures that products stay secure during fast handling without falling, even at high speeds. It's widely used in the automatic detection, sorting, arranging, handling, and cartoning of soft-bag and boxed products, such as powder material like milk powder, protein powder, flour, detergent powder, etc.

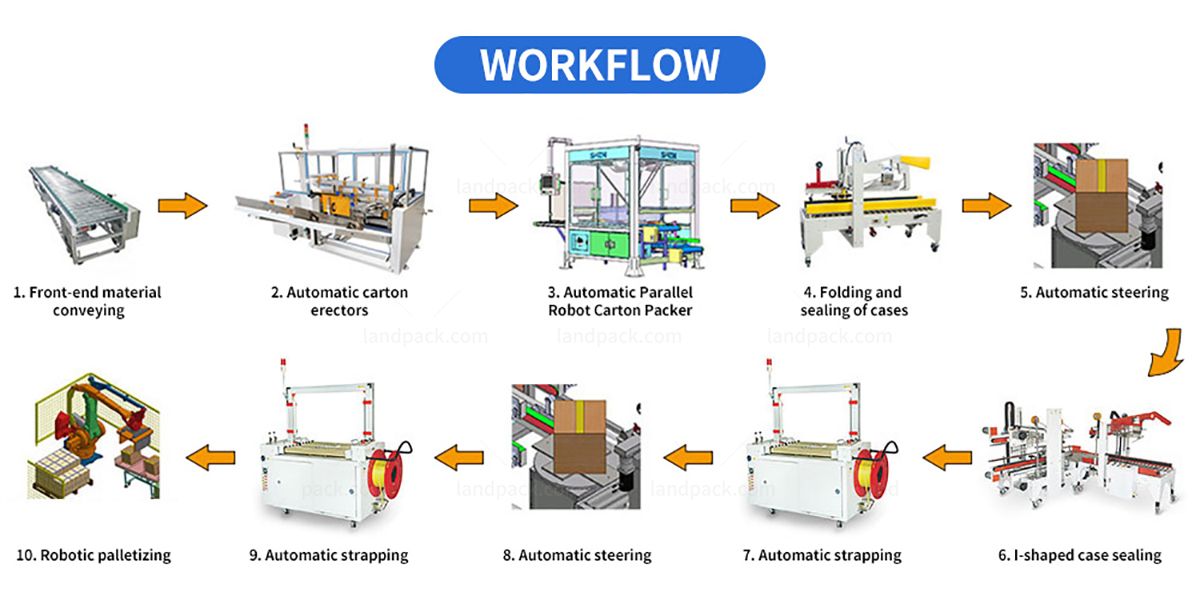

Workflow:

1. Front-end material conveying

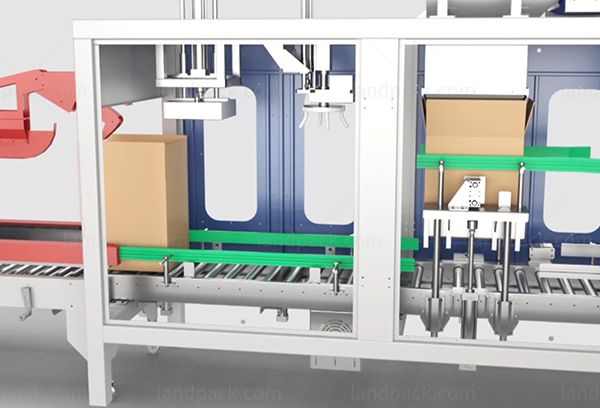

2. Automatic carton erectors

3. Automatic Parallel Robot Carton Packer

4. Folding and sealing of cases

5. Automatic steering

6. I-shaped case sealing

7. Automatic strapping

8. Automatic steering

9. Automatic strapping

10. Robotic palletizing

| Box Case Sealer Sealing Machine | |||||

Model | LD-ZHJ300 | ||||

Power supply | 220V, 50Hz, 0.75kW | ||||

Air pressure requirement | 0.5-0.8MPa | ||||

Machine material | Aluminum + stainless steel | ||||

Applicable | L: 120-300mm, W: 30-150mm, H: 20-60mm | ||||

Size of carton | Customizable | ||||

| Box material | 300-450g cardboard paper, corrugated paper | ||||

Working speed | 30-50 cartons/min | ||||

Machine size | 4008*1354*1633 mm | ||||

Weight | About 1500kg | ||||

| Carton erecting machine | |||||

Carton opening speed | 10-12 cartons/min | ||||

Carton size range | L: 270-450*W: 150-400*H: 100-400mm (Min and max cannot exist at the same time) | ||||

Power supply | 220V, 50/60Hz, 1 Phase | ||||

Power | 2400W | ||||

Adhesive tape width | 48/60/75mm | ||||

Carton storage quantity | 80-100pcs(800-1000mm) | ||||

Air consumption | 450NL/min | ||||

Air compressing | 6kg/cm³ | ||||

Discharge table height | 600+30 mm | ||||

Machine size | L2100*W2100*H1450mm | ||||

Machine weight | 450Kg | ||||

| Automatic Carton Packing Machine | |||||

Model | LD-B8 | LD-B18 | LD-B30 | LD-B42 | LD-B48 |

Capacity | 480case/h | 1100case/h | 1800case/h | 2500case/h | 2800case/h |

Air consumption | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ |

Power | 3.7KW | 3.7KW | 4.5KW | 4.5KW | 5.2KW |

Suitable products | Glass bottles, pet bottles, tin cans, bags, small boxes, and so on(customized) | ||||

Packing way | Paper carton packer, plastic boxes(customized) | ||||

Packing method | Side push, drop, servo, sprocket, robot, spider hand(customized) | ||||

| Carton Box Case Sealer | |||||

Voltage | 220V, 60HZ | ||||

Table height | 620-900mm | ||||

Tape | W: 48-79mm | ||||

Carton size | L: 200-600*W: 150-500*H: 150-500mm | ||||

Machine weight | 165KG | ||||

Machine Key Components:

Feature:

1. High-Precision Servo Packing: Utilizes full servo-driven motion for exact control at rates of 60–70 cases/min.

2. Nordson Adhesive Unit: Integrated with industry-leading glue systems for reliable, long-term durability.

3. Robotic Case Loader: High-flexibility robotics allow for dynamic product orientations and diverse layouts.

4. Tailored Configurations: Scalable design accommodates oversized dimensions and specialized packaging formats.

Get Price & More Detail