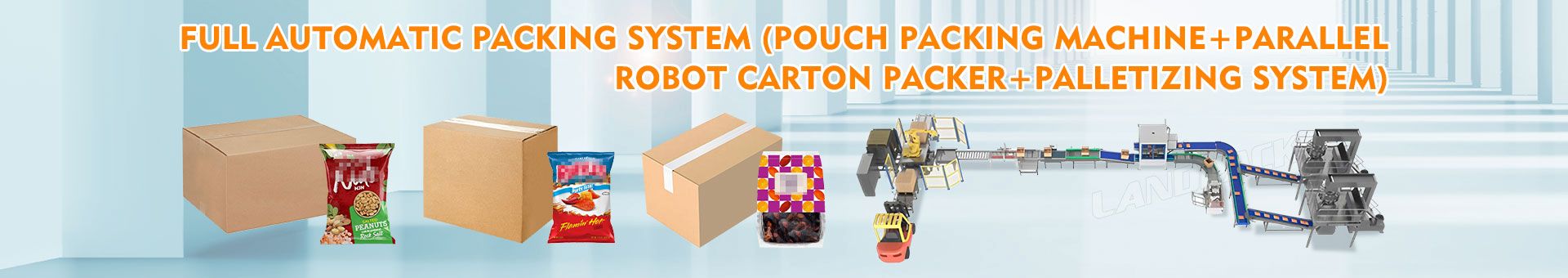

Powder Horizontal Premade Pouch Doypack Case Packaging Systems

Model: LDSP-260AS

The packing system combines auger dosing, weighing, and automatic case packing into one complete solution for granular and powder products. Equipped with screw feeder, vacuum feeding system, powder filling machine, 4-head linear weigher, check weigher, rotary arranging table, carton erector, and carton sealer, perfect for pouch packing.

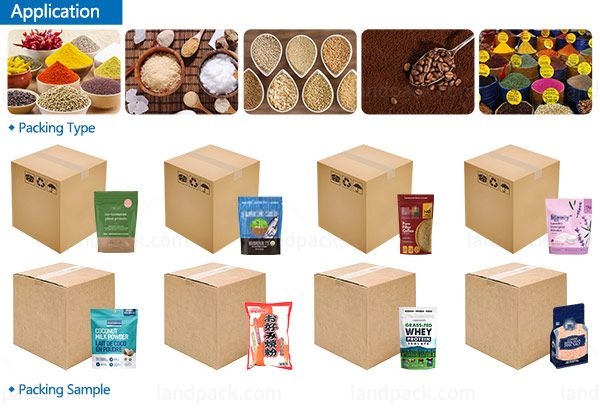

Application:

This packing system is suitable for automatic pouch packing and case packing of both granular and powder products, including rice, sugar, salt, seeds, coffee beans, nuts, pet food kibbles, milk powder, protein powder, flour, spice powder, seasoning, feed additives, and chemical powders.

Application:

This packing system is suitable for automatic pouch packing and case packing of both granular and powder products, including rice, sugar, salt, seeds, coffee beans, nuts, pet food kibbles, milk powder, protein powder, flour, spice powder, seasoning, feed additives, and chemical powders.

Package Type:

Compatible with premade pouches commonly used for granular and powder products, including flat pouches, stand-up pouches, zipper pouches, spout pouch and gusset pouches.

Suitable Products:

Designed for automatic weighing, filling, and cartoning of both granules and powders:

1. Food products: rice, sugar, salt, coffee beans, nuts, milk powder, protein powder, flour, and spice.

2. Daily chemical products: detergent powder, washing powder, and deodorizer granules.

3. Industrial and agricultural products: feed additives, premixes, seed granules, fertilizer additives, and chemical powders.

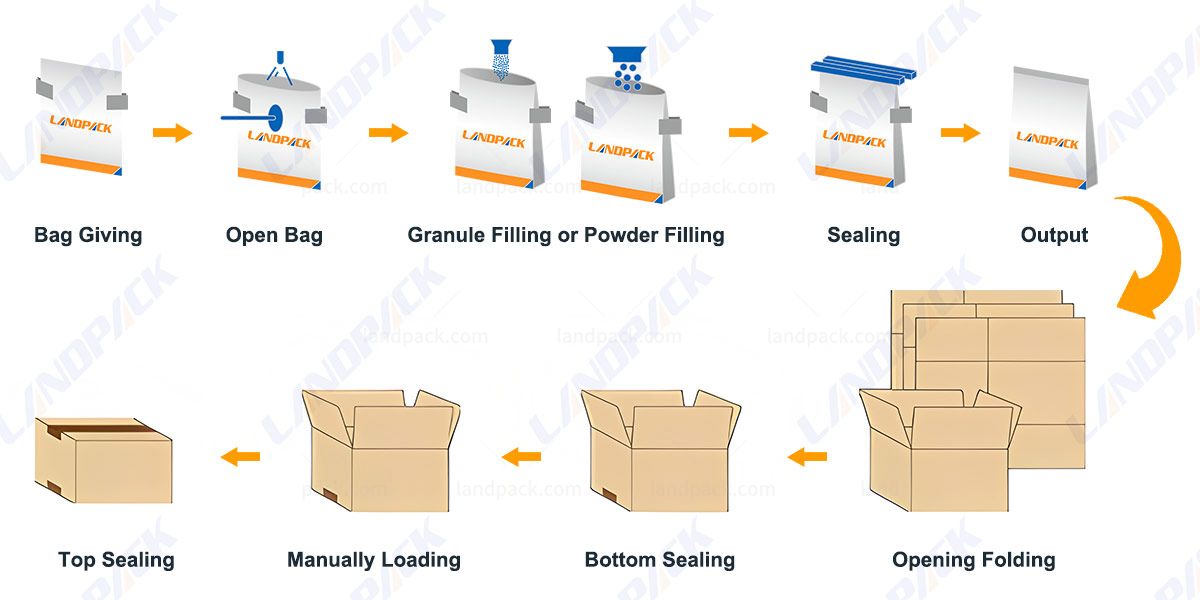

Workflow:

1. Material Feeding: Powder or granule materials are conveyed automatically by vacuum feeder into the dosing system.

2. Weighing & Metering: Auger filler or four-head linear weigher accurately measures products according to preset weights.

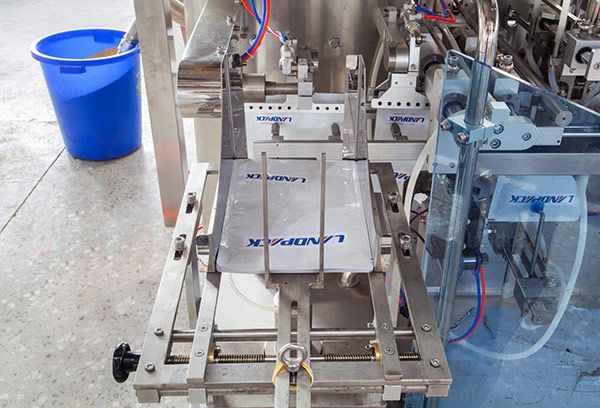

3. Filling: Measured materials are filled into bags smoothly

4. Weight Inspection: Finished packs pass through the check weigher to remove any underweight or overweight products.

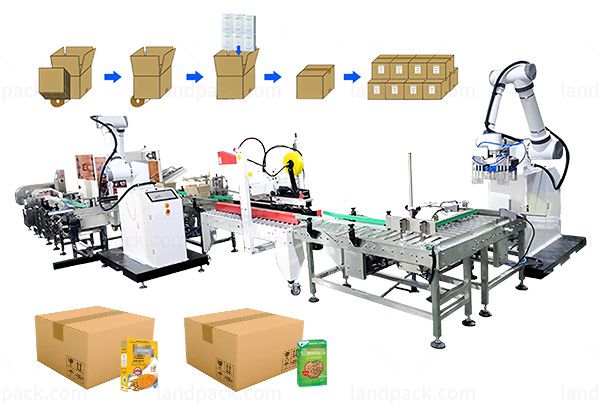

5. Finished Product Conveying: Cartons are automatically formed and positioned by the case erector.

6. Carton Erecting: Cartons are automatically formed and positioned by the case erector.

7. Case Packing: Bags are automatically loaded into cartons in the required arrangement.

8. Case Sealing & Output: Filled cartons are sealed and conveyed

| Type | LDSP-160 | LDSP-160L | LDSP-210L | LDSP-260L |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

| Box Case Sealer Sealing Machine | |||||

| Model | LD-ZHJ300 | ||||

| Power supply | 220V, 50Hz, 0.75kW | ||||

| Air pressure requirement | 0.5-0.8MPa | ||||

| Machine material | Aluminum + stainless steel | ||||

| Applicable | L: 120-300mm, W: 30-150mm, H: 20-60mm | ||||

| Size of carton | Customizable | ||||

| Box material | 300-450g cardboard paper, corrugated paper | ||||

| Working speed | 30-50 cartons/min | ||||

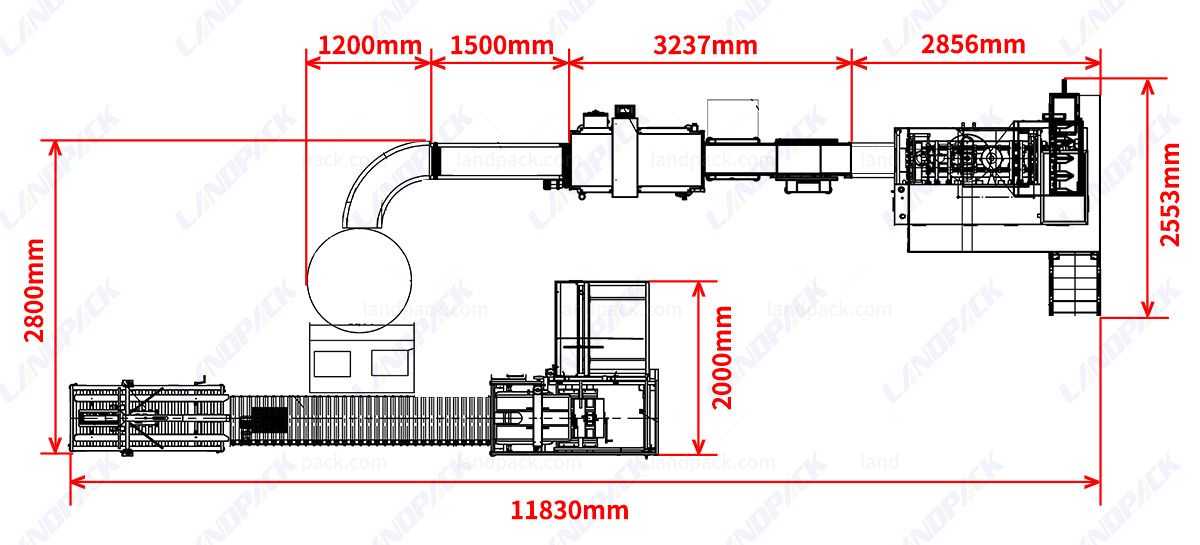

| Machine size | 4008*1354*1633 mm | ||||

| Weight | About 1500kg | ||||

| Carton erecting machine | |||||

| Carton opening speed | 10-12 cartons/min | ||||

| Carton size range | L: 270-450*W: 150-400*H: 100-400mm (Min and max cannot exist at the same time) | ||||

| Power supply | 220V, 50/60Hz, 1 Phase | ||||

| Power | 2400W | ||||

| Adhesive tape width | 48/60/75mm | ||||

| Carton storage quantity | 80-100pcs(800-1000mm) | ||||

| Air consumption | 450NL/min | ||||

| Air compressing | 6kg/cm³ | ||||

| Discharge table height | 600+30 mm | ||||

| Machine size | L2100*W2100*H1450mm | ||||

| Machine weight | 450Kg | ||||

| Automatic Carton Packing Machine | |||||

| Model | LD-B8 | LD-B18 | LD-B30 | LD-B42 | LD-B48 |

| Capacity | 480case/h | 1100case/h | 1800case/h | 2500case/h | 2800case/h |

| Air consumption | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ |

| Power | 3.7KW | 3.7KW | 4.5KW | 4.5KW | 5.2KW |

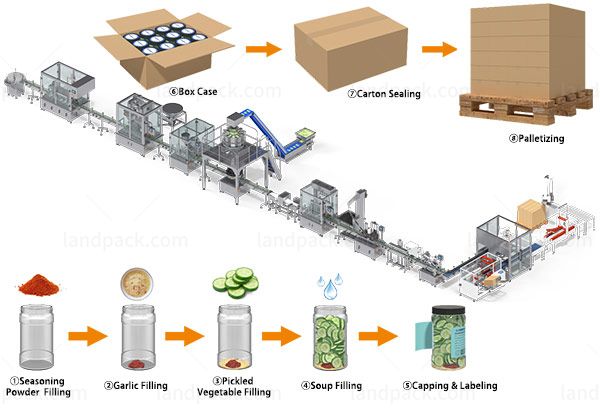

| Suitable products | Glass bottles, pet bottles, tin cans, bags, small boxes, and so on(customized) | ||||

| Packing way | Paper carton packer, plastic boxes(customized) | ||||

| Packing method | Side push, drop, servo, sprocket, robot, spider hand(customized) | ||||

| Carton Box Case Sealer | |||||

| Voltage | 220V, 60HZ | ||||

| Table height | 620-900mm | ||||

| Tape | W: 48-79mm | ||||

| Carton size | L: 200-600*W: 150-500*H: 150-500mm | ||||

| Machine weight | 165KG | ||||

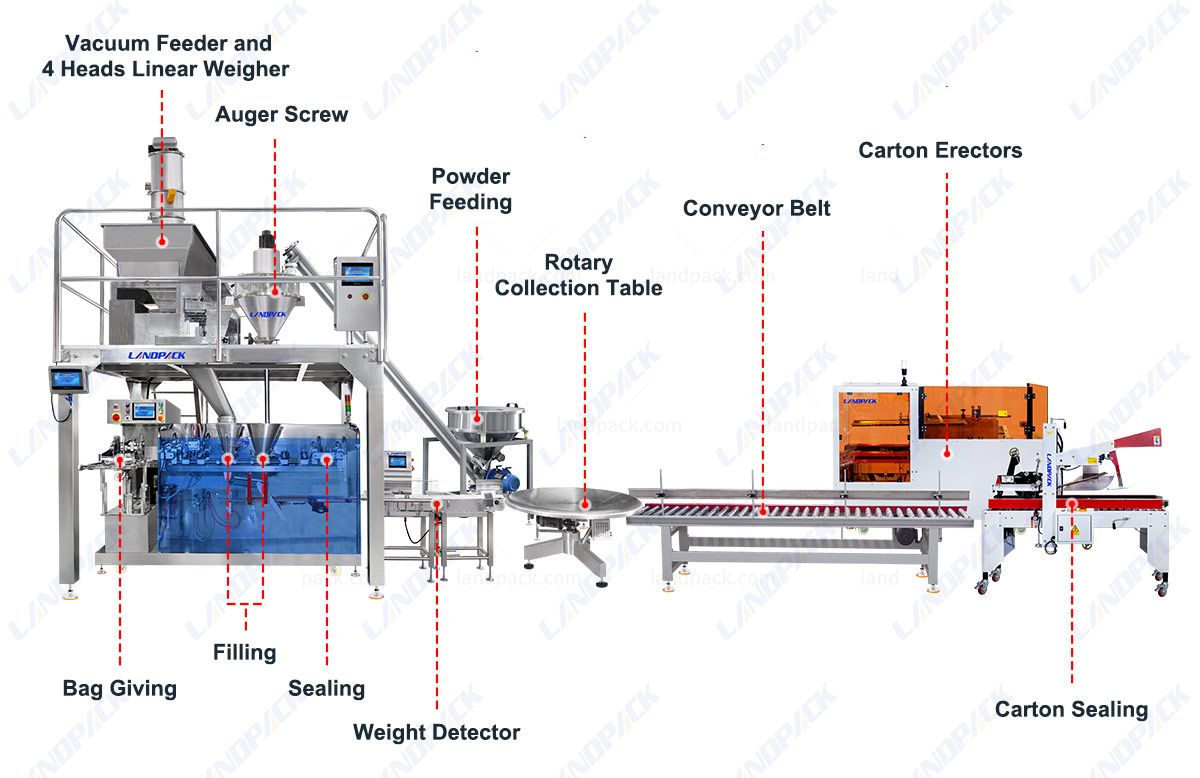

Machine Key Components:

1. Vacuum Feeder and 4 Heads Linear Weigher

2. Auger Screw

3. Powder Feeding

4. Conveyor Belt

5. Carton Erectors

6. Filling Heads

7. Rotary Collection Table

8. Bag Giving Device

9. Sealing Device

10. Weight Detector

Feature:

Siemens PLC Intelligent Control System It is a Siemens PLC with user-friendly HMI that allows reliable operation, precise setting of parameters and simple monitoring. |  |

| Dual Dosing System with Dual Discharge Stations It is equipped with two measuring systems as well as two filling outlets, which allow for an incredibly flexible handling of powders and granules along the same system |

Integrated Dust Removal for Clean Packaging Bag mouths and body dust-removal systems effectively remove any remaining powder that remains after filling |  |

| Full SS304 Stainless Steel Structure The frame as well as the components that interface with the product are constructed out of high-quality food SS304 stainless steel |

Automatic Carton Erecting and Sealing System The packing system is fitted by automatic carton-erectors as well as sealers for cases, which allow direct bag-to-carton packaging with less time and effort. |  |

| Integrated Check Weighing and Quality Control The built-in weight inspection system detects and rejects any non-conforming packaging to ensure consistent weight of the product and a stable quality of packing prior to packing. |

Get Price & More Detail