Automatic Powder Tin Can Jar Filling Seaming Labeling Machine Packing System

Model: Packing System

This automatic powder filling line is a complete tin/can/jar packing system integrating bottle unscrambling, can sterilizing, powder filling, nitrogen flushing sealing, capping, and finished product collection. Designed for hygienic, consistent filling accuracy for powdered food products.

Application:

A powder filling machine specially developed for dairy and nutritional powders.The line integrates accurate dual-head powder filling with multi-station vacuum nitrogen sealing to effectively prevent oxidation and moisture absorption.

Application:

A powder filling machine specially developed for dairy and nutritional powders.The line integrates accurate dual-head powder filling with multi-station vacuum nitrogen sealing to effectively prevent oxidation and moisture absorption.

Package Type:

Designed for powder filling into a tin/can/jar/bottle, Compatible with different container diameters and heights, ensuring stable conveying, accurate filling, and airtight sealing.

Suitable Products:

This packing system is suitable for a wide range of powdered products requiring high hygiene and long shelf life:

Dairy Powders: Milk powder, infant formula, goat milk powder

Nutritional Powders: Protein powder, meal replacement powder, vitamin blends

Food Powders: Coffee powder, cocoa powder, creamer powder, seasoning powder

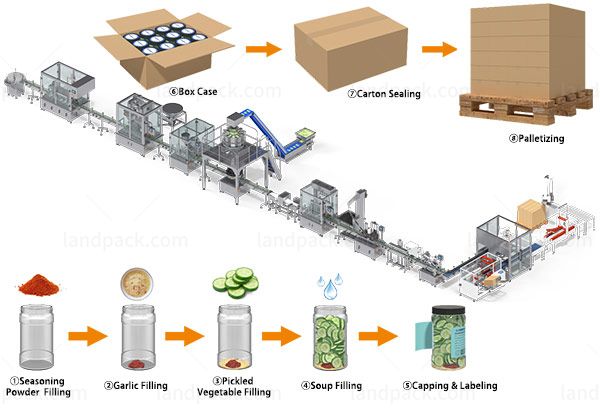

Workflow:

1. Bottle Unscrambling – Empty cans are automatically sorted and aligned for stable downstream conveying.

2. Empty Can Sterilizing – Cans are cleaned and sterilized to ensure a hygienic filling environment.

3. Powder Filling – Dual-head powder filler accurately doses powder into each can.

4. Spoon Feeding – Spoons are automatically fed into cans via vibration feeder.

5. Vacuum Nitrogen Sealing – Oxygen is removed and nitrogen is flushed before sealing to extend shelf life.

6. Can Body Cleaning – Residual powder on the can surface is removed for a clean appearance.

7. Capping – Caps are applied and pressed securely onto sealed cans.

8. Finished Can Output – Completed products are collected and discharged in order.

| Model | LD-PAF03 |

| Filling Range | 100-2000g (Customizable) |

| Filling Speed | 10-25 bottles/min |

| Measurement accuracy | ±1% |

| Power | 4.5 KW |

| Working power supply | 220V, 50Hz |

| Working pressure | 0.6-0.8MPa |

| Weight | 500kg |

| Size | L11782*W3465.09*H2523.52 (mm) |

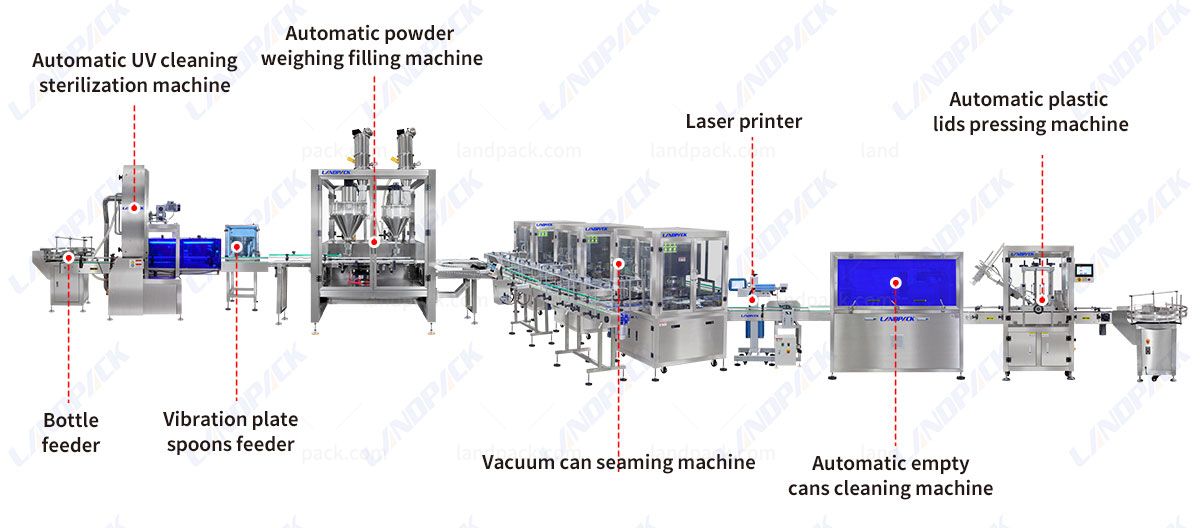

Machine Key Components:

1. Automatic powder weighing filling machine

2. Automatic UV cleaning sterilization machine

3. Laser printer

4. Automatic plastic lid pressing machine

5. Bottle feeder

6. Vibration plate spoons feeder

7. A vacuum can seaming machine

8. Automatic empty cans cleaning machine

Feature:

Complete Powder Can Filling Line Design It integrates bottle unscrambling and empty container sterilization, powder filling, nitrogen sealing and flushing, capping and output. |  |

| Dual-Head Powder Filling System This ensures high accuracy of filling and a consistent dosing of milk powders and fine powders, helping to reduce weight loss and product deviation. |

Vacuum Nitrogen Flushing Sealing (3 Stations) Effectively replaces oxygen in cans to prolong shelf life, stop the formation of oxidation and preserve freshness of powder. |  |

| High Hygiene Structure With empty can sterilization and cylinder body cleaning and food-grade contact components, that meet strict requirements for food safety. |

Stable Can Handling & Sealing A precise and accurate spoon-feeding system, precise positioning of the can and secure capping assure an uncluttered seal and uniform appearance. |

|

Get Price & More Detail