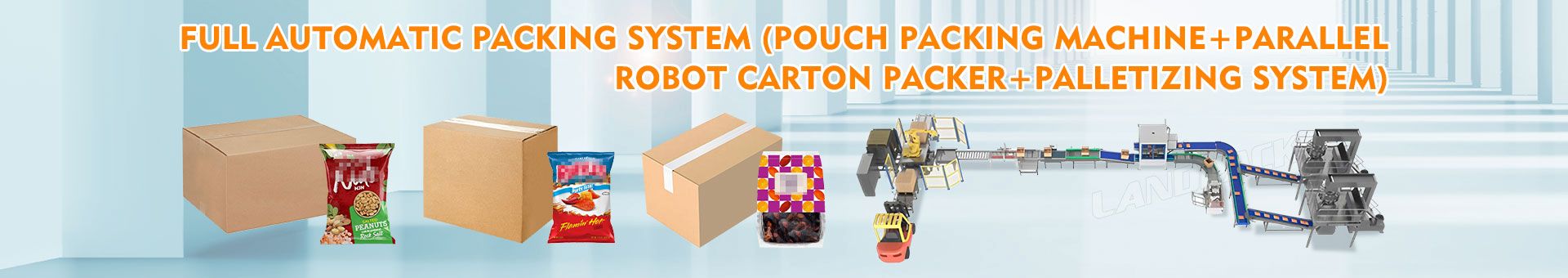

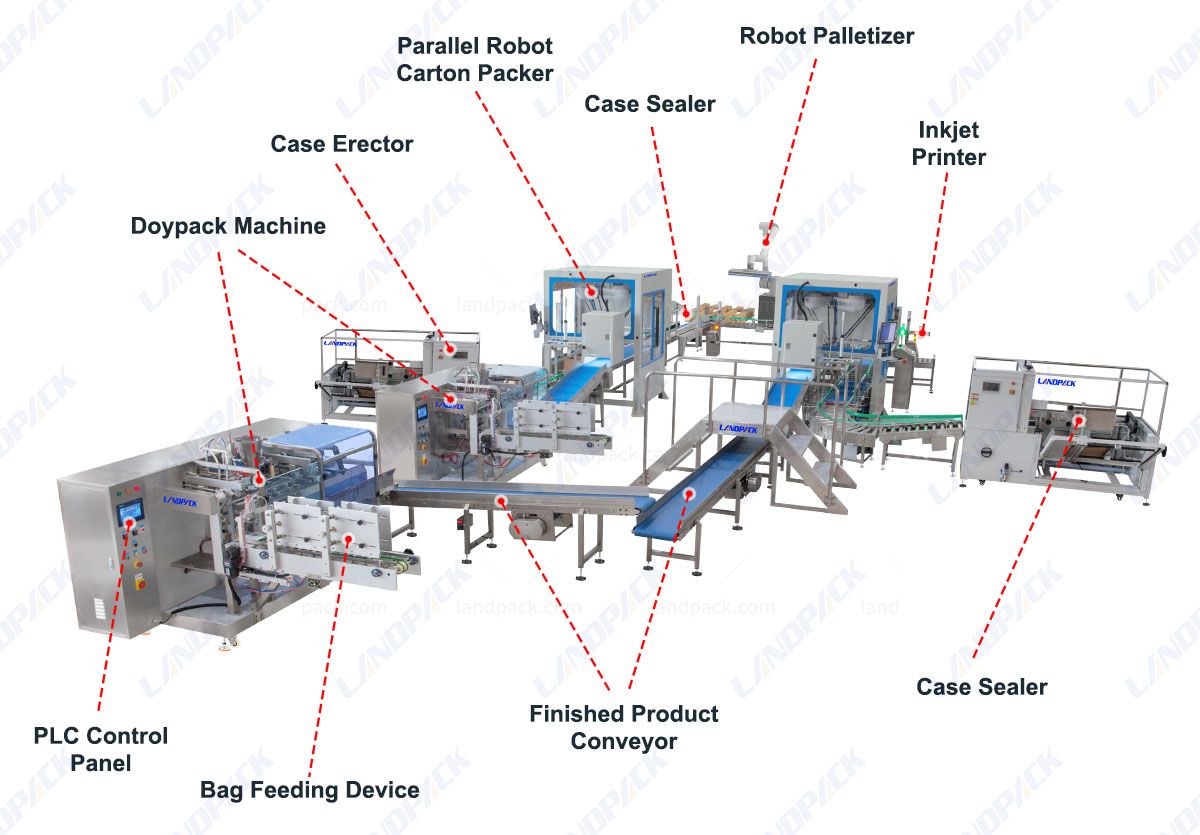

Bagging Cartoning Palletising System | Automatic Horizontal Pouch Packing Machine

Model: Bagging Cartoning Palletising System

Packaging system that combines doypack pouch loading and packing, packaging cases, cartoning and palletizing. Perfect for food packaging systems as well as production lines that are high-efficiency.

Application:

Packing system has been made for production lines that are high-efficiency that require the use of fully automated doypack pouches, from pouch filling and sealing and output feeding, to cartoning and robotic case packing through stretching wrapping and palletizing.

Application:

Packing system has been made for production lines that are high-efficiency that require the use of fully automated doypack pouches, from pouch filling and sealing and output feeding, to cartoning and robotic case packing through stretching wrapping and palletizing.

Package Type:

Designed for versatility, this automated system accommodates various pre-formed bags and cardboard cases. It is fully compatible with diverse formats, including stand-up doypacks, zippered bags, flat pouches, spout designs, quad-seal bags, and other pre-made flexible containers.

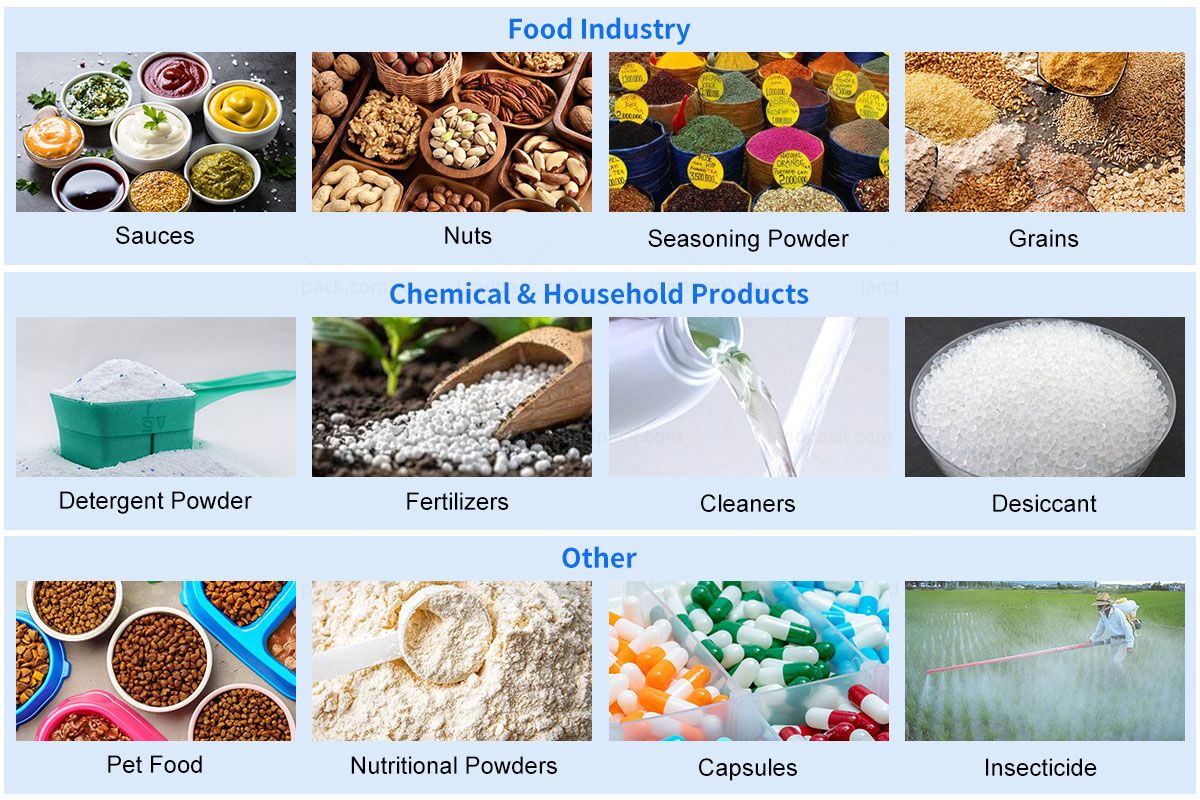

Suitable Product:

This integrated packaging line is designed for medium- to high-output production of bagged food and non-food products. The horizontal pouch machine handles a wide variety of materials, while the robotic cartoner and palletizer support stable downstream automation. Typical applications include:

Food Products: snacks, nuts, beans, pasta, grains, dried fruits, powders, sauces in spout pouches, pet food

Daily & Chemical Products: detergent pods, dishwasher powder, cleaning granules, cosmetic refills

Industrial & Miscellaneous Goods: small parts, hardware kits, agricultural seeds, chemical granules

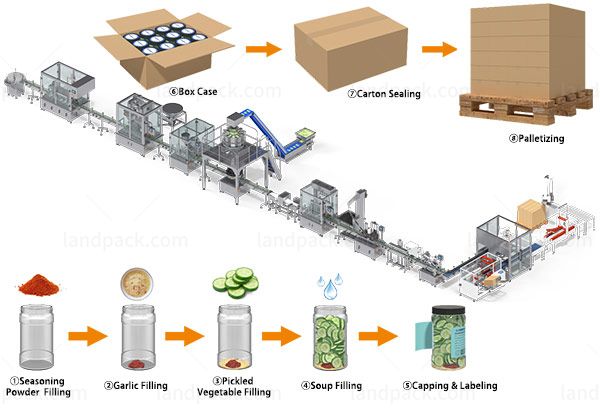

Workflow:

1. Doypack Pouch Packaging

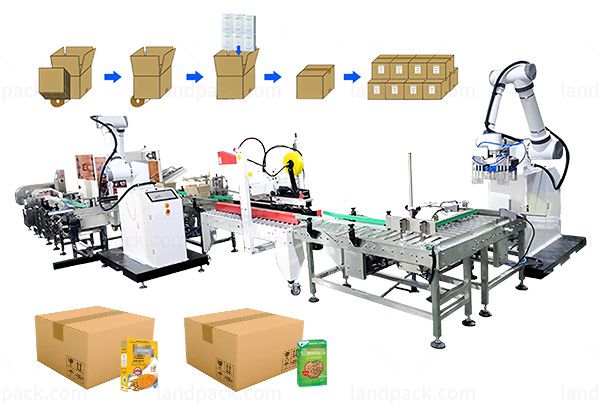

2. Carton Opening

3. Carton Packing

4. Weight Detection

5. Carton Sealing

6. Coding

7. Palletizing

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, Doypack, Box Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Hole, Kraft Paper Bag, Side Gusset Bag etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

| Coding machine | |

| Resolution | 1280*800 |

| Language | 17 |

| Printing Rows | 1-4 (5*7 dot),1-5(5*5 dot) |

| Dot Matrix | *5,5*7,7*9,10*12,12*16,18*24,24*32 |

| Printing Contents | Date, time, batch number, serial number, lot number,bar code, QR code, logo, pattem, variable data, and text. |

| Speed | 285m/min |

| Character Height | 1.8-15mm |

| Printing Head to the Base | 3m |

| Printing Distance(Printing head to the object) | <30mm (Printing head to the object) |

| Temperature and Humidity | 5-45°C,30-90% |

| Power | 220W |

| Voltage | 200-240V,AC,50/60Hz |

| Size | 370*310*510mm |

| Net Weight | 23kg |

| Automatic Parallel box packing workstation | |||

| Model | LD-D-800-4-1 | LD-D-1200-4-1 | LD-D-1600-4-1 |

| Number of Axes | 3+1 | 3+1 | 3+1 |

| Arm Reach | 800 | 1200 | 1600 |

| Maximum Pickup Height | 330 | 425 | 750 |

| Rated Load | 3 | 8 | 8 |

| Maximum Load | 5 | 15 | 15 |

| Repeatability | R±0.1 | R±0.1 | R±0.1 |

| Standard Cycle Time | 240 | 200 | 185 |

| Automatic case erecting machine | |

| Model | LD-CF50H |

| Power supply | 220V 50Hz |

| Maximum packing size | 450*400*400mm |

| Minimum packing size | 250*200*150mm |

| Working height | 600mm |

| Sealing speed | 6-10 boxes/min |

| Applicable tape | (W)48-75mm x(L)0-914mm |

| MechanicalDimensions | 2200*2050*1450mm(L*W*H) |

| Machine weight | About 400kg |

| Automatic Carton sealing machine | |

| Machine Model | LD-FXC50 |

| Voltage | 220V 50Hz |

| Power | 400W |

| Case Size | (L)200-600mm*(W)150-500mm*(H)150-500mm |

| Tape Width | 48-72mm |

| Conveying Speed | 18m/min |

| Height of Worktable | 600-750mm |

| Machine Size | About 1760*890*1450mm(L*W*H) |

| Weight detector | |||||

| Model | LD10 | LD100 | LD201 | LD401 | LD1000 |

| Weight Range | 10-99g | 100-200g | 201-400g | 401-999g | 1000-10000g |

| Rate | 65bag/min | 60bag/min | 50bag/min | 45bag/min | 40bag/min |

| Precision | ±0.5g | ±1g | |||

| Minimum scale | 0.1g | ||||

| Predesign pattern | 10kinds | ||||

| Size | 1050*681*1260 | ||||

| Voltage | 220V | ||||

| Power | 300W | ||||

| Automatic Robot palletizer | |||

| Model | LD60-PL | LD120-PL | LD1800-PL |

| Arm Reach | 2000mm | 2400mm | 3060mm |

| Maximum Load | 60kg | 120kg | 180kg |

| Weight | 500kg | 1050kg | 1120kg |

| Pallet Dimensions | 1200*1200 | 1200*1200 | 1400*1400 |

| Palletizing Speed | 8 cycle/min | 8 cycle/min | 8 cycle/min |

| Stretch Wrapping | |

| Pallet Size | L1200 × W1200 mm |

| Turntable Speed | Variable speed with soft start & stop function |

| Wrapping Height | 1800 mm |

| Loading Weight | MP 303B: 2000 kg; MP 303A: 1000 kg |

| Pre-stretch Ratio | 150% |

| Turntable Height | 550 mm |

Machine Key Components:

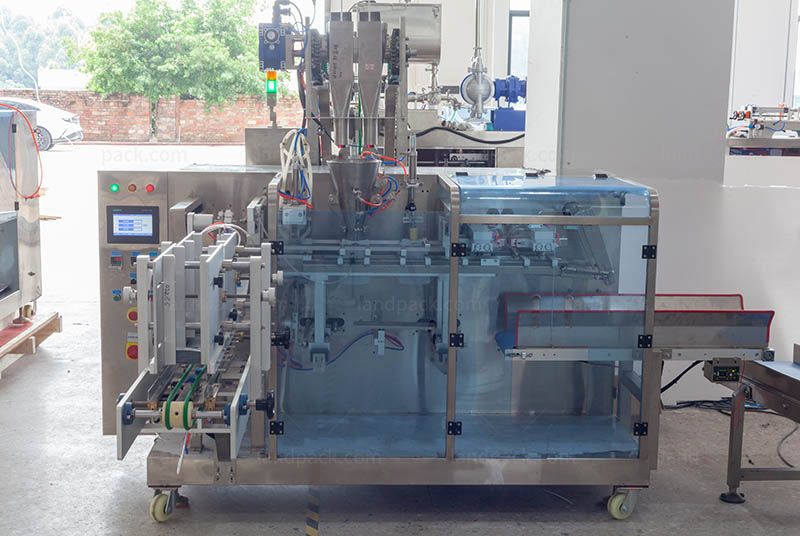

1. Doypack Machine

2. Product Conveyor

3. Case Erector

4. Parallel Robot Carton Packer

5. Weight Checker

6. Case Sealer

7. Inkjet Printer

8. Robot Palletizer

9. Stretch wrapping machine

Feature:

Horizontal Premade Pouch Packing Machine Operating with consistent and fluid motion, the horizontal pouching assembly automatically handles the picking, opening, filling, and sealing of pre-made pouches. |  |

| Finished Product Conveyor The exit conveyor transitions sealed bags to the packing zone efficiently, maintaining consistent product alignment and ensuring a seamless transition from the bagging stage to later steps. |

Cartoning Workstation The cartoning assembly oversees the forming of cases, the grouping of bags, and the precise insertion of pouches into their respective boxes. |  |

| Parallel Robotic Picker A pair of parallel robots performs rapid bag sorting and loading, guided by high-precision motion control systems. |

Weighing System Embedded inline scales validate the mass of every pouch prior to boxing, automatically discarding any units that fall outside of set parameters. |  |

| Palletizing Robot The palletizing system organizes loaded cartons onto pallets with exact layer alignment and customizable stacking configurations. |

Stretch Film Wrapping Machine The wrapping station coats completed pallets with consistent layers of stretch film, enhancing cargo security and stability for warehousing and transit. |  |

Get Price & More Detail