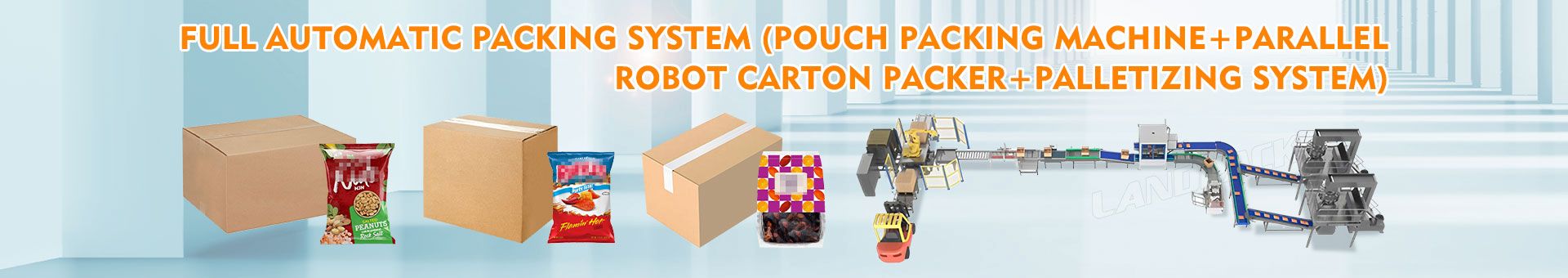

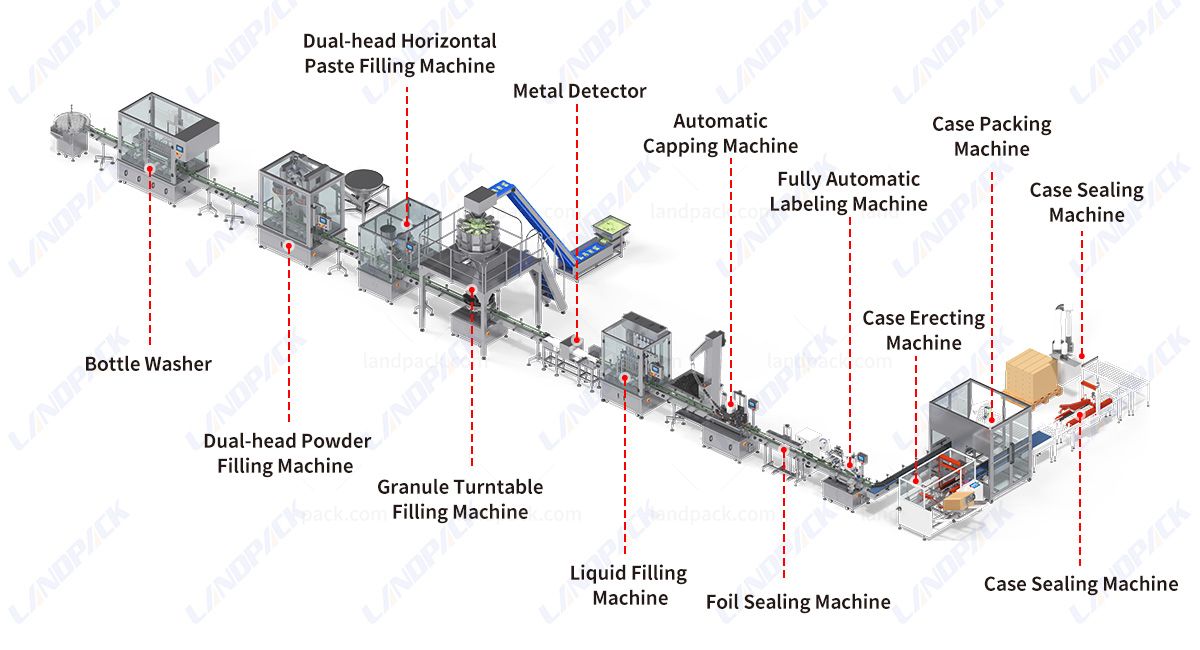

Intelligent Food Packaging Systems With Robot Packer & Palletizer

Model: Food Packaging Systems

Maximize efficiency with our automated food packaging systems. From robotic packing to smart palletizing, this system ensures high-speed, accurate, and hygienic packaging for various food products.

Application:

Our food packaging systems with robotic packers and palletizers are ideal for food factories, especially pickled and canned food production, cartoning and palletizing.

Application:

Our food packaging systems with robotic packers and palletizers are ideal for food factories, especially pickled and canned food production, cartoning and palletizing.

Package Type:

This filling, packaging and palletizing line is made for different rigid packaging containers like tin cans plastic bottles, glass jars and other can-type sealed containers.

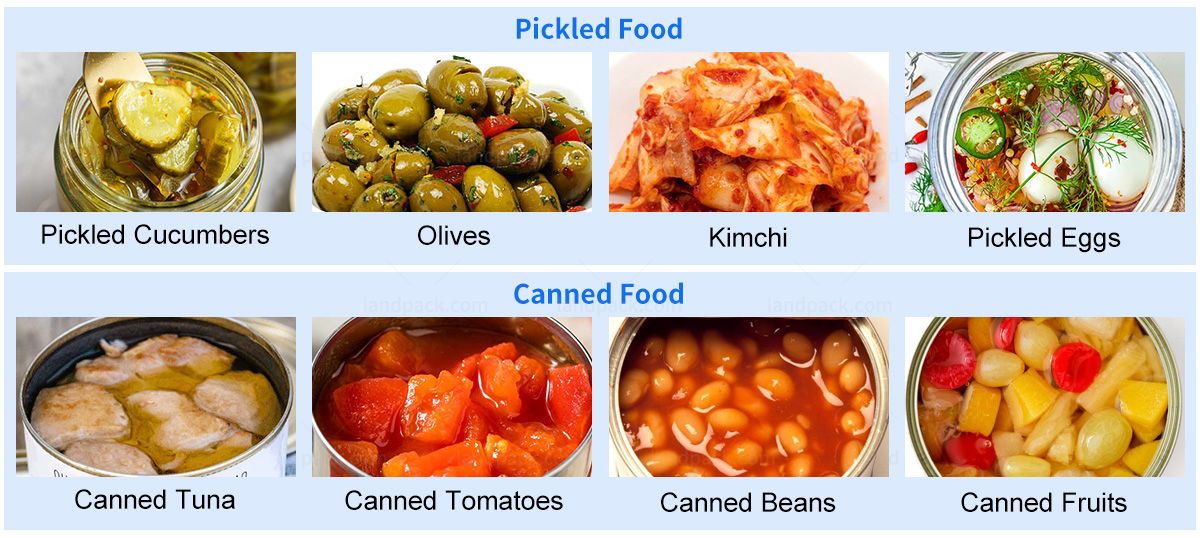

Suitable Products:

This filling, packing and palletizing line has been specifically designed for canned and pickled food.

Pickled Foods: It is ideal for packaging products made of pickled ingredients, such as olives, cucumbers, pickled eggs, kimchi and pickled onions.

Canned Foods: A wide variety of canned food items are used in production, such as canned tuna and canned tomatoes canned soup, canned beans and canned fruit.

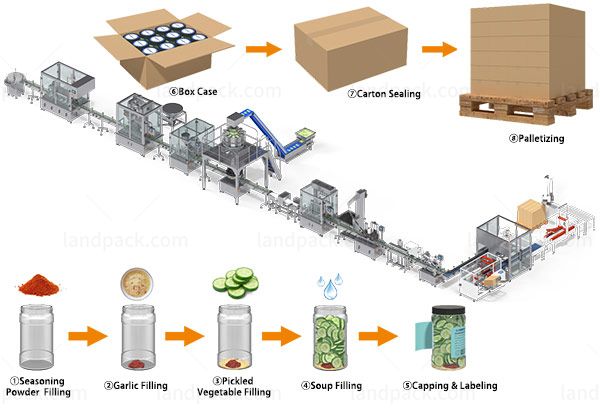

Workflow:

1. Seasoning Powder Filling

2. Garlic Filling

3. Pickled Vegetable Filling

4. Soup (Brine) Filling

5. Canning/Bottling & Labeling

6. Box Case Packing

7. Carton Sealing

8. Palletizing

Powder filling machine | |

Measuring mod | Auger screw dosing model |

Container size | Φ30-130mm H50-250mm(can be customized) |

Filling weight | 50g-500g(can be customized) |

Filling accuracy | 500g,≤±1% |

Filling speed | 20-30 bottles/min(depend on the material and weight) |

Auger hopper | 50L |

Power supply | 220V, 50Hz/60Hz |

Piston filling machine | |

Filling head | 2 Heads(can be customized) |

Metering way | Piston pump |

Filling range | 100-1000ml(can be customized) |

Filling speed | 40-50 bpm |

Bottle width/diameter | 30-130mm(can be customized) |

Machine body | SS 304 |

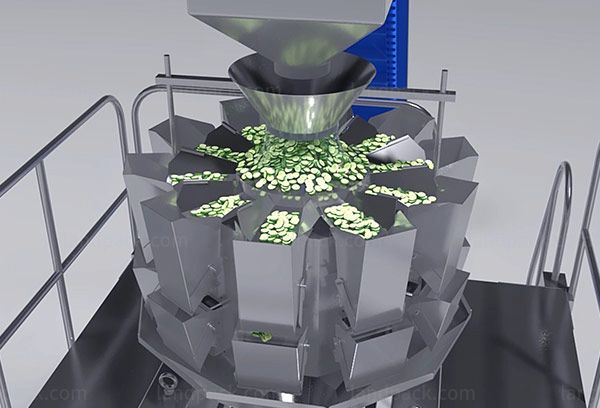

Granule filling machine | |

Material of machine | Stainless Steel 304, 1.2mm thickness |

Filling Speed | 25-30bpm(Whole line speed) |

Measuring Method | Weighing system |

Filling photocell sensor | Included, no bottle no filling |

Filling Accuracy | 0.5-1.0 g |

Air Consumption | 0.6-0.8 MPa, 0.03 m³/min |

Machine weight | 350kg |

Conveyor belt motor | 2.5KW, Single phase 220V 50/60Hz |

Self-flow filling machine | |

Filling head | 6 Heads(can be customized) |

Metering way | Gravity self-flow |

Filling range | 100-1000ml(can be customized) |

Filling speed | 30-40 bpm |

Bottle width/diameter | 30-130mm(can be customized) |

Pair Clamp type capping machine | |

Material of machine | SS304 |

Cover diameter | Diameter 30-80mm |

Min Cover height | 10mm |

Bottle height size | 100-250mm (Customized is acceptable) |

Speed | 30-40bpm (depends on material and cover size) |

Conveyor size | (L)3000*(W)114*(H)900mm |

Machine size | (L)2000*(W)*900*(H)1600mm |

Machine weight | N.W250kg, G.W320kg |

Power | 220V, 50HZ, 2KW |

Air consumption | 0.5-0.7mpa |

Automatic Aluminum foil sealing machine | |

Cooling mould | Water cooling |

Sealing diameter | Max 60 mm(can be customized) |

Sealing speed | 1-20meters/min |

Induction head size | (L*W*H) 670×125×95 mm |

Main machine dimension | (L*W*H) 600*460*1100mm |

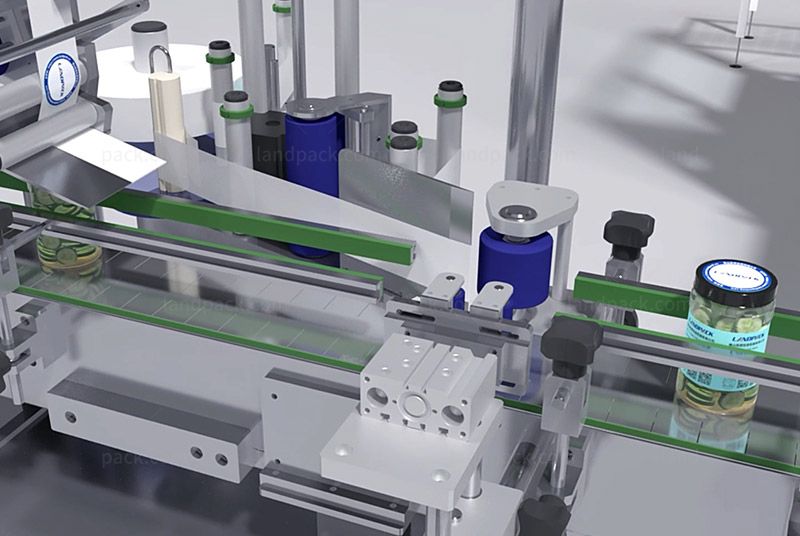

Labeling Machine | |

Model | LD-RBL |

Labeling Speed | 20-60 bottles/min |

Accuracy | ± 1mm |

Label Width | 100-200mm (customizable) |

Bottle Size | φ30-φ80mm (customizable) |

Inner Diameter of label roll | φ76mm |

Outer Diameter of label roll | φ330mm |

Air Source | 4-6 kg, 30 L/min |

Dimension | 2000*800*1600mm |

Voltage/Weight | 220V, 50Hz/60Hz, 2000W |

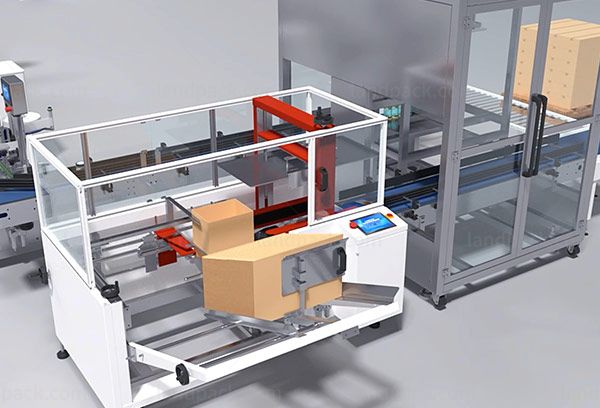

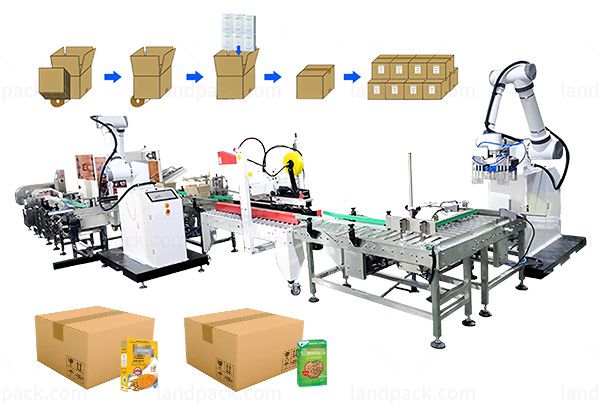

Carton erector | |

Carton opening speed | 10-12 cartons/min |

Carton size range | L: 270-450*W: 150-400*H: 100-400mm (Min and max cannot exist at the same time) |

Power supply | 220V, 50/60Hz, 1 Phase |

Power | 2400W |

Adhesive tape width | 48/60/75mm |

Carton storage quantity | 80-100pcs(800-1000mm) |

Air consumption | 450NL/min |

Air compressing | 6kg/cm³ |

Discharge table height | 600+30 mm |

Machine size | L2100*W2100*H1450mm |

Machine weight | 450Kg |

| Carton Box Case Sealer | |

Voltage | 220V/380V, 50HZ/60HZ |

Table height | 600-750mm |

Tape | W: 48-75mm |

Speed | 480*600 cartons/h |

Carton size | L: 320-500*W: 180-500*H: 180-500mm |

Machine weight | 110kg+350kg |

Machine size | 1910*1150*1400 |

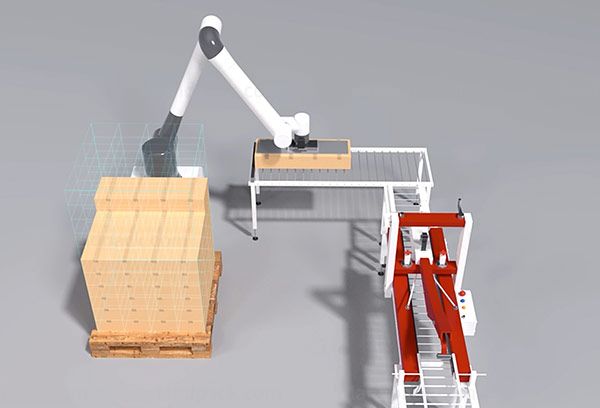

| Robot palletizing | |

Structural form | Six-joint robot |

Degree of freedom | Six-axis |

Payload | 25KG |

Maximum radius of motion | 1805 |

Motion range | 1 axis: ±180°, 2 axis: -125°~+90°, 3 axis: -77°~202°, 4 axis: ±180°, 5 axis: ±125°, 6 axis: ±360° |

Main body weight | 191kg |

Power | 7.7KW |

Machine Key Components:

1. Bottle Washer

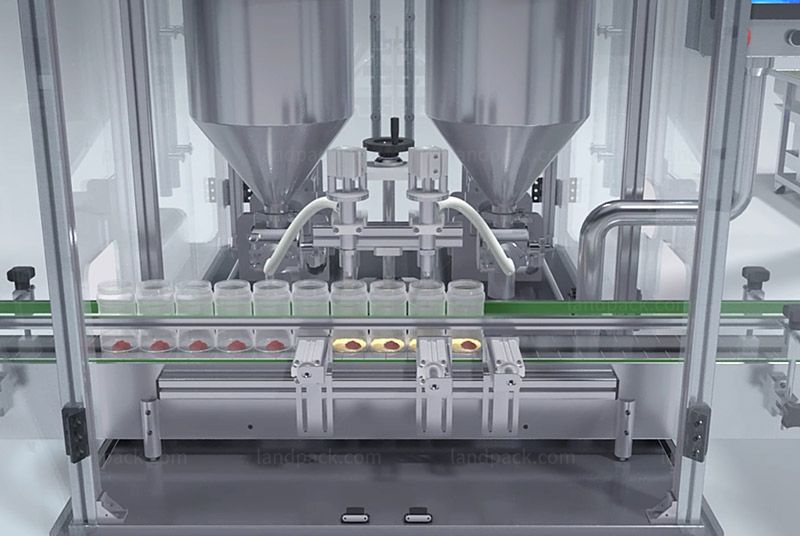

2. Dual-head Powder Filling Machine

3. Dual-head Horizontal Paste Filling Machine

4. Granule Turntable Filling Machine

5. Metal Detector

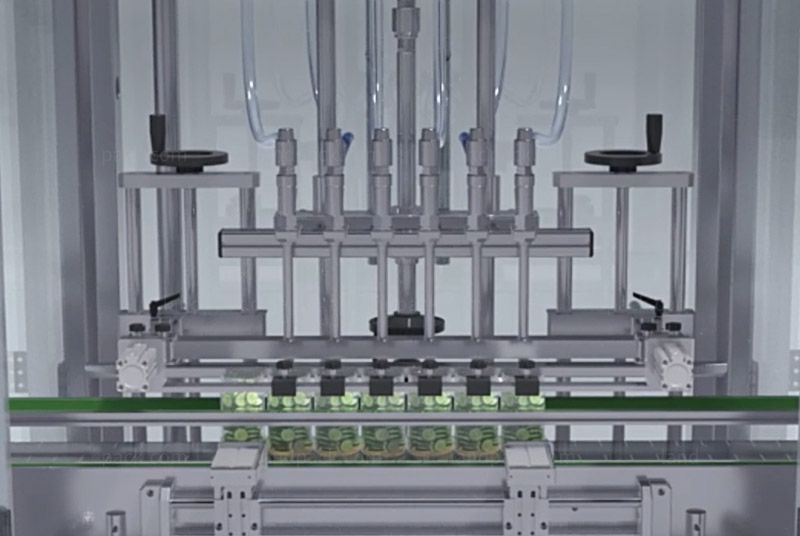

6. Liquid Filling Machine

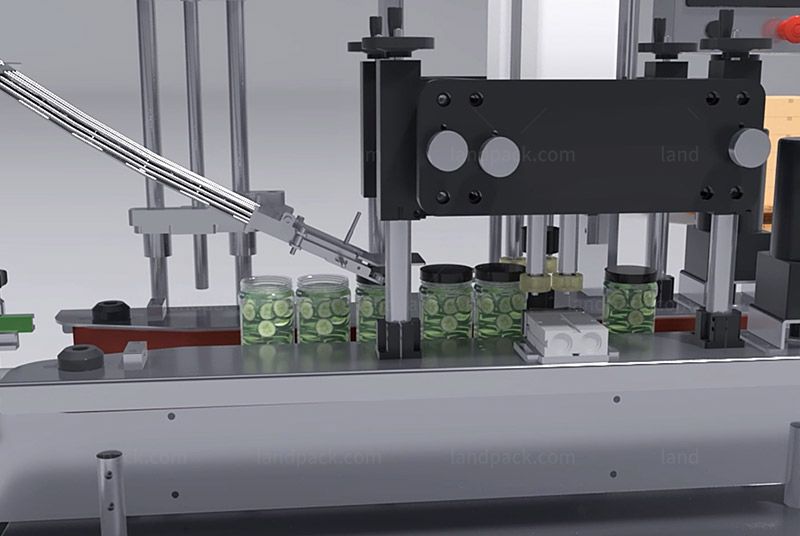

7. Automatic Capping Machine

8. Foil Sealing Machine

9. Case Packing Machine (Case Erector/Packer)

10. Case Sealing Machine

Feature:

Dual-head Powder Filling Machine Equipped with high-accuracy servo-driven fillers, this unit guarantees precise powder dosing and rapid filling cycles to maximize overall output. |  |

| Dual-head Paste Filling Machine Engineered for semi-liquids and high-viscosity substances, this dual-head configuration delivers a steady and uniform filling performance. |

Granule Turntable Filling Machine This module automates the measurement of materials through a rotating mechanism, ensuring a continuous and stable filling flow. |  |

| Liquid Filling Machine Capable of processing various liquid types with exact volumetric precision, this unit minimizes waste while maintaining a sanitary filling environment. |

Automatic Capping Machine A fast and efficient sealing solution for bottles, jars, and canisters that ensures every container is tightened securely. |  |

| Labeling Machine Applies labels with extreme accuracy at high velocities, significantly boosting the visual quality and tracking capabilities of the product. |

Case Erector Automatically shapes and seals carton bottoms, providing rigid and reliable boxes to support uninterrupted manufacturing. |  |

| Case Packing Robot This workflow executes product loading rapidly and effectively, lowering manual labor requirements and improving operational uniformity. |

Robot Palletizer Organizes cartons onto pallets according to pre-defined layouts, optimizing end-of-line efficiency while saving time and human effort. |  |

Get Price & More Detail