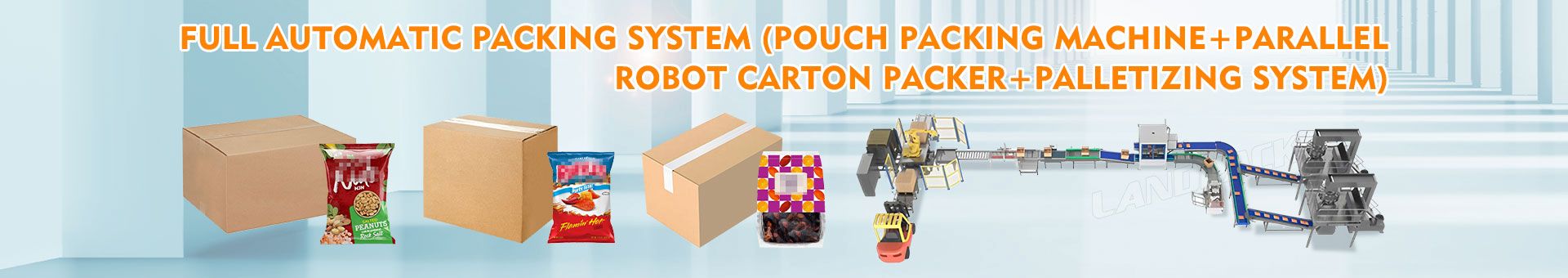

Automatic Cartoning Packing System With Heat Shrink Machine

Model: Cartoning Packing System

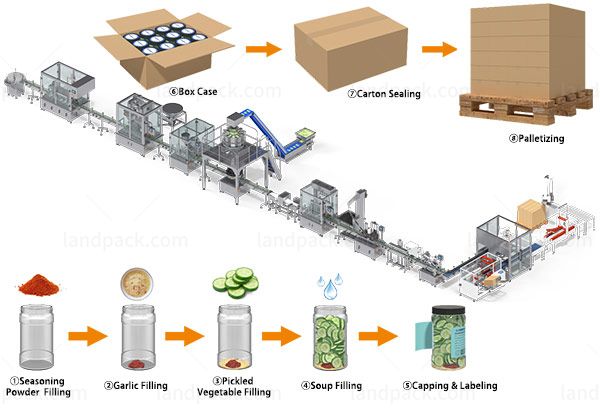

This automated system combines case packing with heat-shrink technology for a total end-of-line solution.

Application:

Optimized for food, beverages, and industrial goods, it streamlines cartoning and film-wrapping into one workflow.

Application:

This automated system combines case packing with heat-shrink technology for a total end-of-line solution. Optimized for food, beverages, and industrial goods, it streamlines cartoning and film-wrapping into one workflow.

Package Type:

This automatic case packing system with heat shrink machine is suitable for loading heat shrink products from different industries into cases.

Suitable Products:

This Robot Case Packer With Palletizing System is extensively used in the food, daily products that are already packed in boxes.

Food: Sauce, candy, cakes, drinks, sauce, instant noodles, chocolate, coffee, etc.

Daily Products: Accessories, mobile phone, shampoo, accessory, tissue, facial mask, toothpaste, crayons, etc.

Medical Supplies: Mask, syrup, medicine, condoms, adhesive bandage, e-cigarette, etc

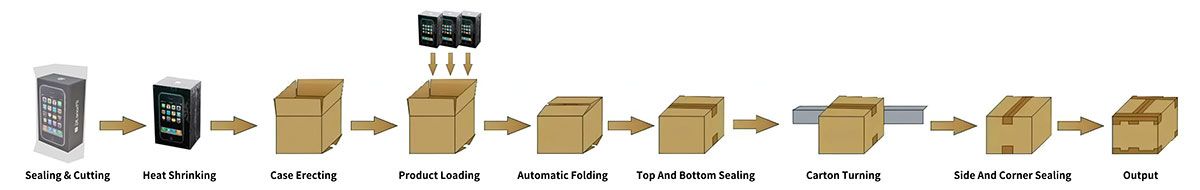

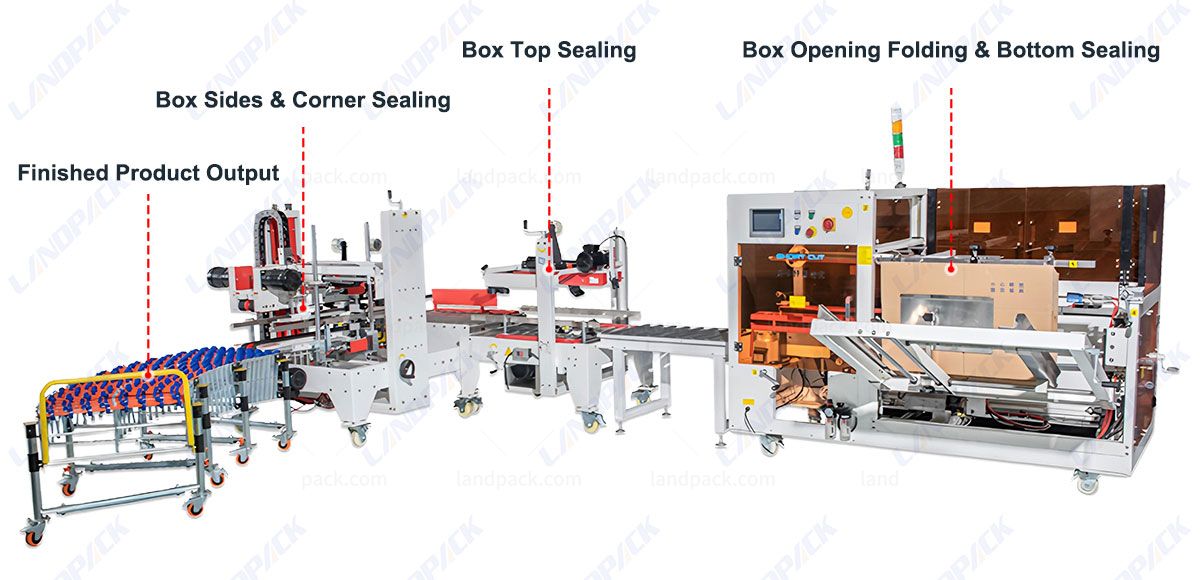

Workflow:

1. Sealing & Cutting – Products are first sealed and cut into neat packaging by L type packing machine.

2. Heat Shrinking – The package goes through heat shrinking to achieve a tight, professional look.

3. Case Erecting – Cartons are automatically formed and prepared for loading.

4. Product Loading – Finished products are neatly placed into the carton.

5. Automatic Folding – The carton flaps are folded automatically to save time.

6. Top and Bottom Sealing – Both the top and bottom of the carton are securely sealed with tape.

7. Carton Turning – The carton is rotated for further sealing steps.

8. Side and Corner Sealing – Additional sealing reinforces the carton for extra strength.

| L type sealing cutting machine | |||||

Power Supply | AC 220V 1PH 60Hz | ||||

Power | 1.8KW | ||||

Max. Packing Size | L<500mm; W<430mm; H<130mm | ||||

Sealing Size | L550*W450mm | ||||

Table Height | 800mm | ||||

Packing Speed | 15-30pcs/min | ||||

Air Source | 6kgf/c㎡ | ||||

Shrink Film | POF | ||||

Film Size | (W)≤550mm;(D)≤250mm;(G)≤35KG | ||||

Sealing Type | L type full closed | ||||

Machine Size | (L)1800×(W)800×(H)1600mm | ||||

Package Size | (L)1850×(W)920×(H)1620mm | ||||

G./N. Weight | 390/320kg | ||||

| Heat shrink machine | |||||

Power Supply | AC 220/380V 3PH 50/60 Hz | ||||

Power | 12KW | ||||

Table Height | 800mm | ||||

Conveying Load | 30KG | ||||

Conveyor Speed | 1-15m/min | ||||

Tunnel Size | L1500×W450×H220mm | ||||

Overall Dimensions | L1910×W700×H1320mm | ||||

Package Size | L1960×W850×H1470mm | ||||

G./N. Weight | G./N. Weight | ||||

| Carton erecting machine | |||||

Carton opening speed | 10-12 cartons/min | ||||

Carton size range | L: 270-450*W: 150-400*H: 100-400mm (Min and max cannot exist at the same time) | ||||

Power supply | 220V, 50/60Hz, 1 Phase | ||||

Power | 2400W | ||||

Adhesive tape width | 48/60/75mm | ||||

Carton storage quantity | 80-100pcs(800-1000mm) | ||||

Air consumption | 450NL/min | ||||

Air compressing | 6kg/cm³ | ||||

Discharge table height | 600+30 mm | ||||

Machine size | L2100*W2100*H1450mm | ||||

Machine weight | 450Kg | ||||

| Carton Box Case Sealer | |||||

Voltage | 220V/380V, 50HZ/60HZ | ||||

Table height | 600-750mm | ||||

Tape | W: 48-75mm | ||||

Speed | 480*600 cartons/h | ||||

Carton size | L: 320-500*W: 180-500*H: 180-500mm | ||||

Machine weight | 110kg+350kg | ||||

Machine size | 1910*1150*1400 | ||||

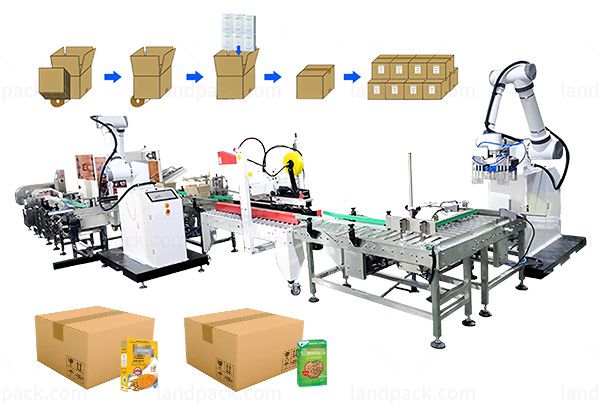

Machine Key Components:

1. Case Erector

2. Automatic L-Type Sealing Machine

3. Shrink Wrapping Machine

4. H-Type Sealer

Feature:

1. L-Type Sealer: High-precision film cutting and sealing for a clean, professional finish.

2. Heat Shrink Tunnel: Uniform heat application for tight, secure, and aesthetic packaging.

3. Carton Erector: Automated box forming to increase labor efficiency and structural consistency.

4. Universal Conveyor: Flexible, seamless product transfer across the entire production line.

5. Top & Bottom Sealer: Synchronized dual-surface sealing for reliable carton protection.

6. Corner Sealer: Targeted edge reinforcement to prevent damage during transit.

Get Price & More Detail