Case Packing Robot | Packaging Systems

Model: Carton Packing System

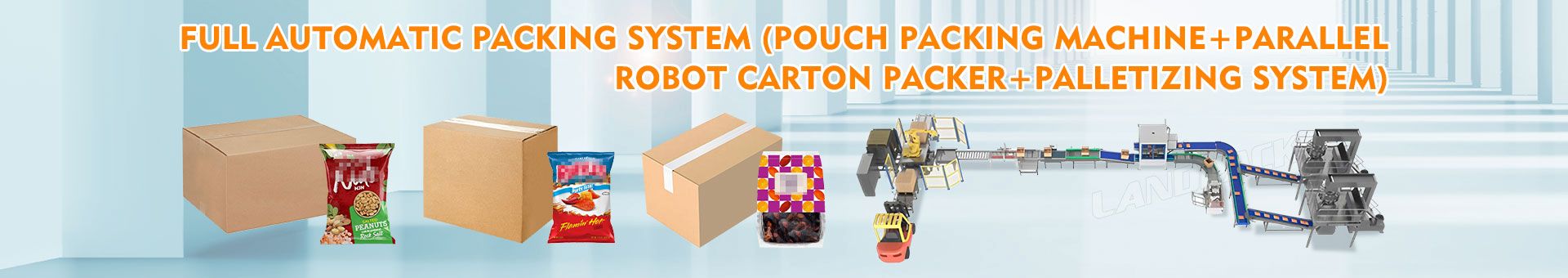

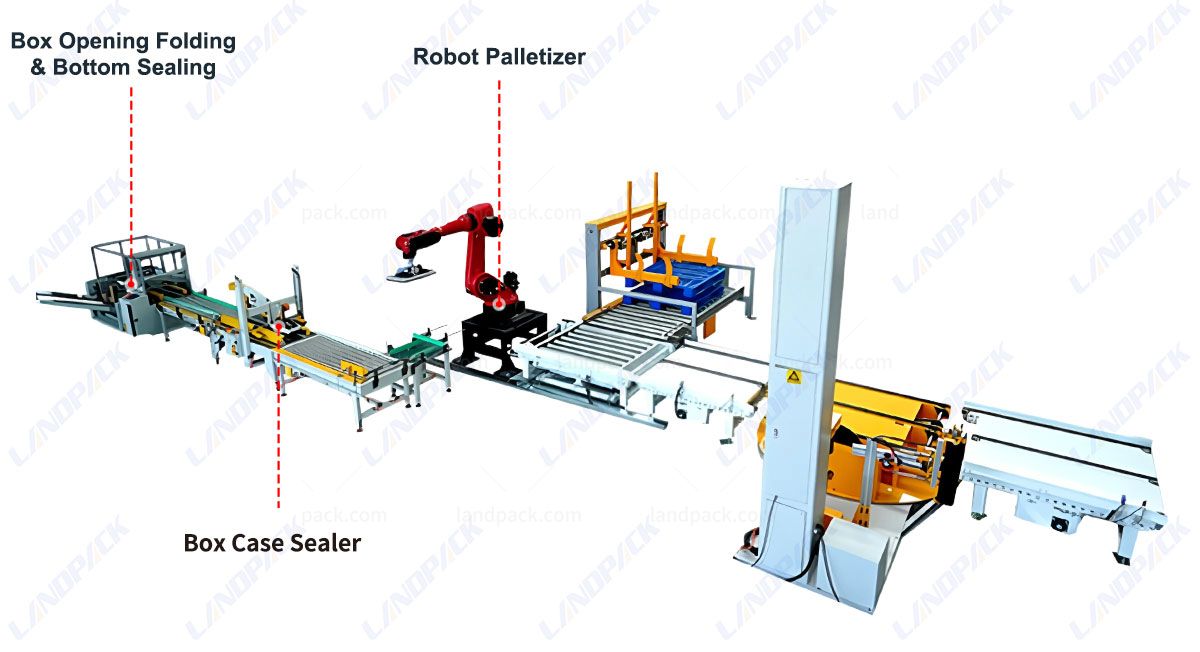

This automatic packing system is applied to an end-of-line packaging solution, integrating carton erecting, sealing, palletizing, and pallet wrapping into one continuous workflow.

It is ideal for carton-based secondary packaging and palletized tertiary packaging.

Application:

This automatic packing system is designed for end-of-line carton packing and palletizing of finished products such as snacks, biscuits, confectionery, detergent, spice, frozen food, daily chemical products, and household goods.

Application:

This automatic packing system is designed for end-of-line carton packing and palletizing of finished products such as snacks, biscuits, confectionery, detergent, spice, frozen food, daily chemical products, and household goods.

Package Type:

This packaging systems are designed for automatic handling of cartons, cases, and boxes throughout erecting, sealing, and palletizing processes.

Suitable Products:

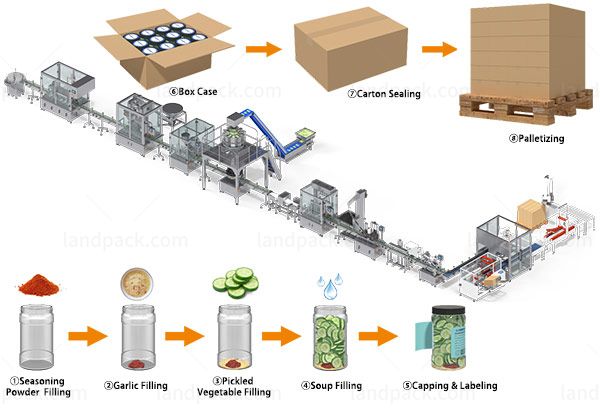

This automated packing system is designed for carton erecting, carton sealing, and palletizing of products:

Food & Beverages: Snack cartons, biscuit boxes, chocolate bar boxes, bottled beverage cases, instant noodle boxes, dairy product cartons.

Daily Chemical Industry: Detergent cartons, shampoo and liquid soap boxes, tissue paper cases, household cleaner boxes, personal care product cartons.

Pharmaceutical & Health Products: Medicine cartons, health supplement boxes, vitamin bottle cases, medical supply cartons, nutraceutical product boxes.

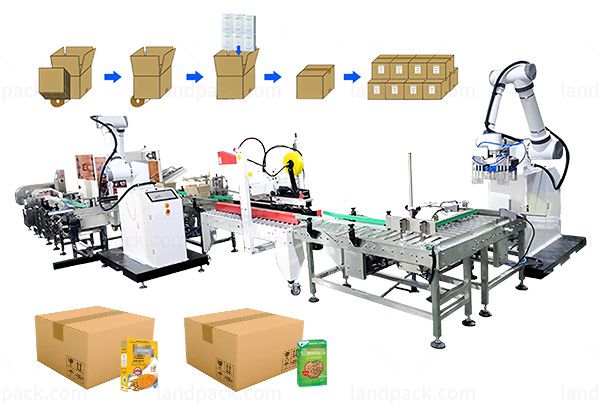

Workflow:

1. Carton Forming: The case erector automatically forms and conveys empty cartons to the packing line.

2. Carton Sealing: Filled cartons are sealed securely to ensure stable box output.

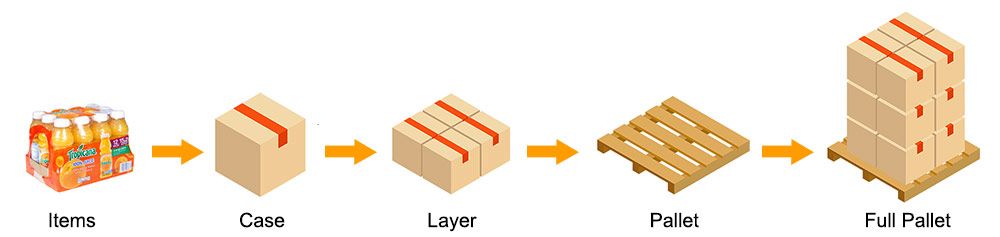

3. Pallet Supplying: The pallet dispenser automatically feeds empty pallets to the palletizing station.

4. Palletizing: The palletizer stacks cartons onto pallets according to preset patterns.

5. Pallet Wrapping: Completed pallets are wrapped with stretch film for safe storage and transportation.

| Carton erecting machine | |||||

Carton opening speed | 10-12 cartons/min | ||||

Carton size range | L: 270-450*W: 150-400*H: 100-400mm (Min and max cannot exist at the same time) | ||||

Power supply | 220V, 50/60Hz, 1 Phase | ||||

Power | 2400W | ||||

Adhesive tape width | 48/60/75mm | ||||

Carton storage quantity | 80-100pcs(800-1000mm) | ||||

Air consumption | 450NL/min | ||||

Air compressing | 6kg/cm³ | ||||

Discharge table height | 600+30 mm | ||||

Machine size | L2100*W2100*H1450mm | ||||

Machine weight | 450Kg | ||||

| Carton Box Case Sealer | |||||

Voltage | 220V, 60HZ | ||||

Table height | 620-900mm | ||||

Tape | W: 48-79mm | ||||

Carton size | L: 200-600*W: 150-500*H: 150-500mm | ||||

Machine weight | 165KG | ||||

| palletizer machine | |||||

Palletizing Speed | 17 cycles/minute | ||||

Payload Capacity | 130 kg / 180 kg | ||||

Repeatability | ±0.5 mm | ||||

Reach (Arm Span) | 3,255 mm | ||||

Degrees of Freedom | 4-axis | ||||

Mounting | Floor-mounted | ||||

Protection Rating | IP67 (standard); Optional IP69K for washdown | ||||

| Stretch Wrapping | |||||

Pallet Size | L1200 × W1200 mm | ||||

Turntable Speed | Variable speed with soft start & stop function | ||||

Wrapping Height | 1800 mm | ||||

Loading Weight | MP 303B: 2000 kg; MP 303A: 1000 kg | ||||

Pre-stretch Ratio | 150% | ||||

Turntable Height | 550 mm | ||||

Carriage Speed | 3 m/minute | ||||

Cut Method | Heater-based cutting | ||||

Packing Speed | 15–30 pallets/hour | ||||

Power | 2.1 kW | ||||

Machine Voltage | 3PH 380V, 50/60 Hz, 20A | ||||

Machine Weight | 1800 kg | ||||

Control System | PLC programmable control | ||||

Working Method | Fully automatic, unmanned operation | ||||

Air Pressure | 0.4–0.7 MPa | ||||

Machine Key Components:

1. Box Opening Folding& Bottom Sealing

2. Robot Palletizer

3. Box Case Sealer

Feature:

Automatic Case Erector Forms cartons accurately and continuously, ensuring stable box supply for downstream packing. |  |

| Carton Sealing Machine Provides consistent I-shape or customized sealing, ensuring strong and reliable carton closure. |

Robotic Palletizer Automatically stacks cartons with precise positioning, supporting multiple pallet patterns and layouts. |  |

| Pallet Dispenser Automatically supplies empty pallets to the palletizing station, reducing manual handling and downtime. |

Pallet Wrapping Machine Applies uniform stretch film wrapping to secure pallet loads and improve transport stability. |  |

Get Price & More Detail