Automatic Feeding And Packing System For Bread, Waffle, Chocolate Bar

Model: LP-350B

The Automatic Feeding and Packing System for Bread, Waffle, and Chocolate Bar is a complete feeding and packing system integrating automatic product arranging, continuous conveying, and horizontal flow wrapping. Designed for baked goods and snacks.

Application:

This feeding and packing system is applied to the automatic arrangement, feeding, and pillow packaging of chocolate biscuits, waffles, bread slices, chocolate bars, bread, pancakes, biscuits, cakes, rusks, and buns.

Application:

This feeding and packing system is applied to the automatic arrangement, feeding, and pillow packaging of chocolate biscuits, waffles, bread slices, chocolate bars, bread, pancakes, biscuits, cakes, rusks, and buns.

Package Type:

Compatible with pillow pouch, back sealing pouch, 3/4 sides sealing bag, sachet, and gusset pouch, the feeding and packing system integrates automatic product alignment with a horizontal flow wrapper to ensure smooth film forming, precise sealing, and consistent bag shapes.

Suitable Products:

This automatic feeding and packing system efficiently handles a wide variety of snack and baked food with high speed and accuracy.

1. Snack Industry: cookies, cheese curls, pretzels, swiss rolls.

2. Baking industry: Chocolate bars, biscuits, buns, wafers.

3. Health & Nutritional Products: Granola bars, protein bars, cereal bars, energy chews.

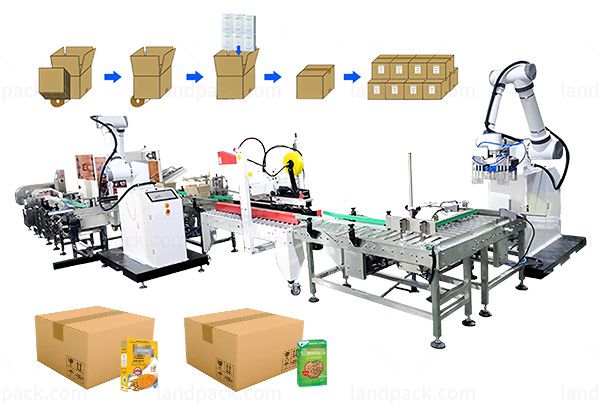

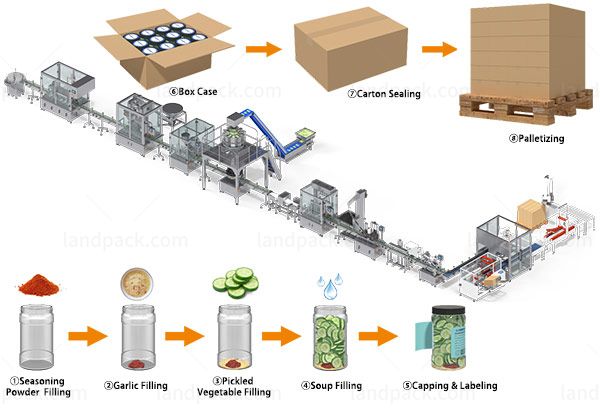

Workflow:

1. Product Loading: Items are loaded onto the infeed conveyor from trays or racks.

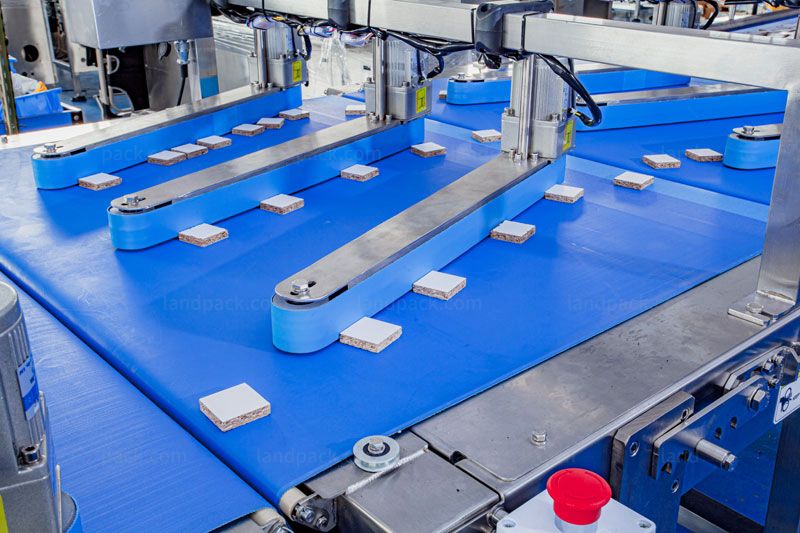

2. Orientation & Alignment: Products are aligned and spaced properly for smooth feeding.

3. Feeding to Packaging Machine: Products are fed continuously into the pillow/flow pack machine.

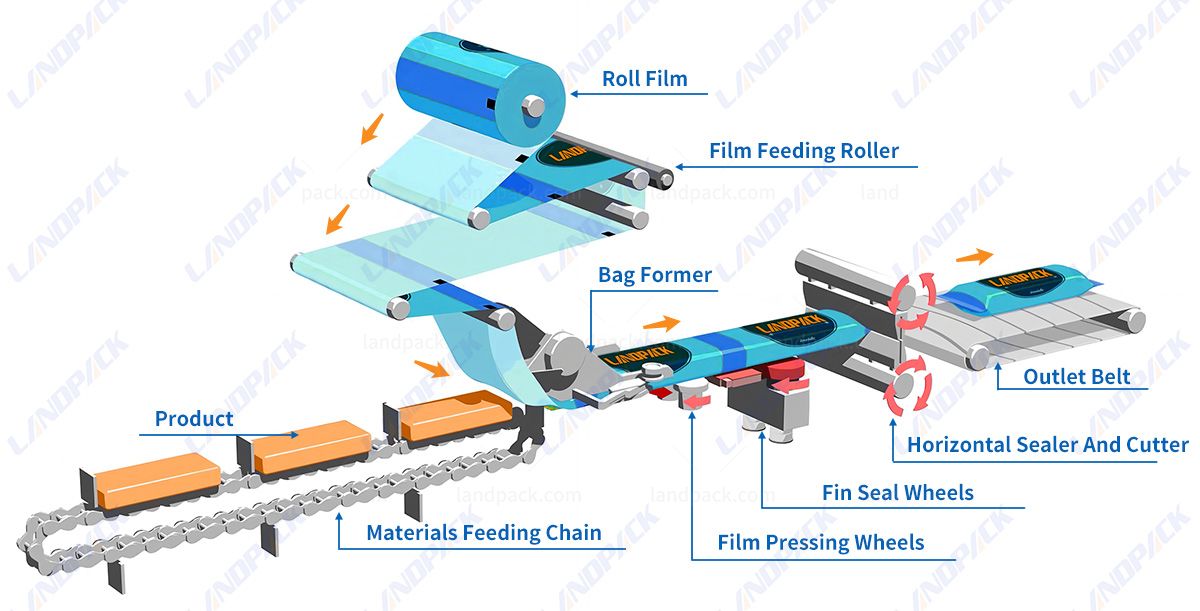

4. Film Forming: Packaging film is pulled, formed, and positioned for filling.

5. Product Insertion & Filling: Items are inserted into the formed bags accurately.

6. Sealing: Bags are heat sealed, forming airtight and neat packages.

7. Cutting & Output: Sealed packages are cut and transferred to the discharge conveyor

| Model | LP-350B |

| Film width | Max.350mm |

| Bag size | 60-190mm(L)*50-160mm(W) |

| Product height | Max 75mm |

| Packing speed | 200-300 bags/min (Depends on material length) |

| Machine size | 7980*3180*1540mm |

| Power voltage | single-phase, AC 220V/60Hz, 5.5kw |

| Material of fame | Machine frame SS201.Contact part: SS304 |

| Packing line | 1+2 / 1+3 |

| Drive | Three servo motors |

| Packaging material | BOPP/CPP, BOPP/VMCPP, BOPP/PE, PET/VMPET/PE, PET/AL/PE, PET/PET, etc. |

| Application | Chocolate bar, biscuits, cookies, bread, cake, Bun, frozen foods, dumpling, frozen meat, etc |

Machine Key Components:

1. Touch screen

2. Up-film feeding system

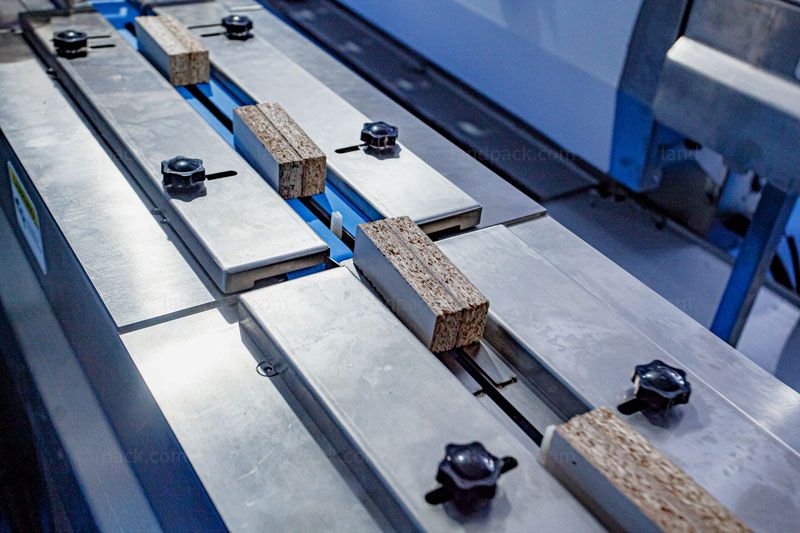

3. Adjustable bag former

4. Product feeding conveyor

Feature:

High-Speed Packaging Capable of packing 500-600 bars, cubes, or clock-shaped items per minute, significantly boosting production efficiency. |  |

| Seamless Feeding Conveyor Smoothly integrates with the production line, ensuring uninterrupted material flow and minimal product jams. |

Hygienic Design Easy to clean with full compliance to food safety standards, maintaining a sanitary processing environment. |  |

| Automatic Stretch Conveyor Guides bars, cubes, or clock-shaped items precisely into the multi-channel sorting and feeding system. |

Precision Sorting System Six high-accuracy SICK sensor-equipped belts ensure consistent product positioning for flawless packaging. |  |

| High-Speed Ink Coding Integrated coding system prints clear batch numbers, expiration dates, or logos accurately at high speed. |

Get Price & More Detail